As part of its partnership with the Chinese manufacturer of 3D printers Farsoon, the Fraunhofer Institute for Material and Beam Technology IWS in Dresden will install an industrial 3D printer that is unique in Europe.

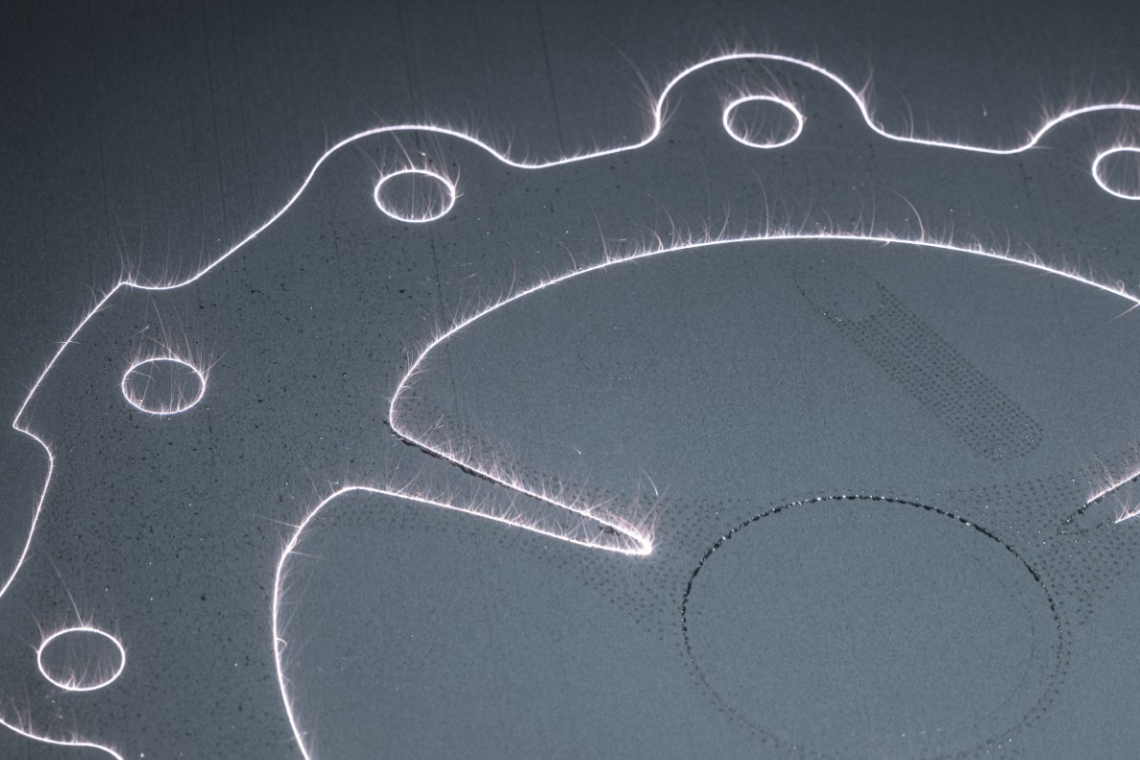

The new AM system is based on selective laser beam melting in a powder bed and is designed to help produce components with complex geometries made of aluminum, titanium, nickel, iron and copper. As part of the joint project "SpreeTec neXt", new manufacturing processes and value chains for the post-coal era are to be established together with the Brandenburg University of Technology Cottbus-Senftenberg (BTU). In addition to the production of hard-to-get spare parts for agriculture, the focus will be on energy technology and machine components.