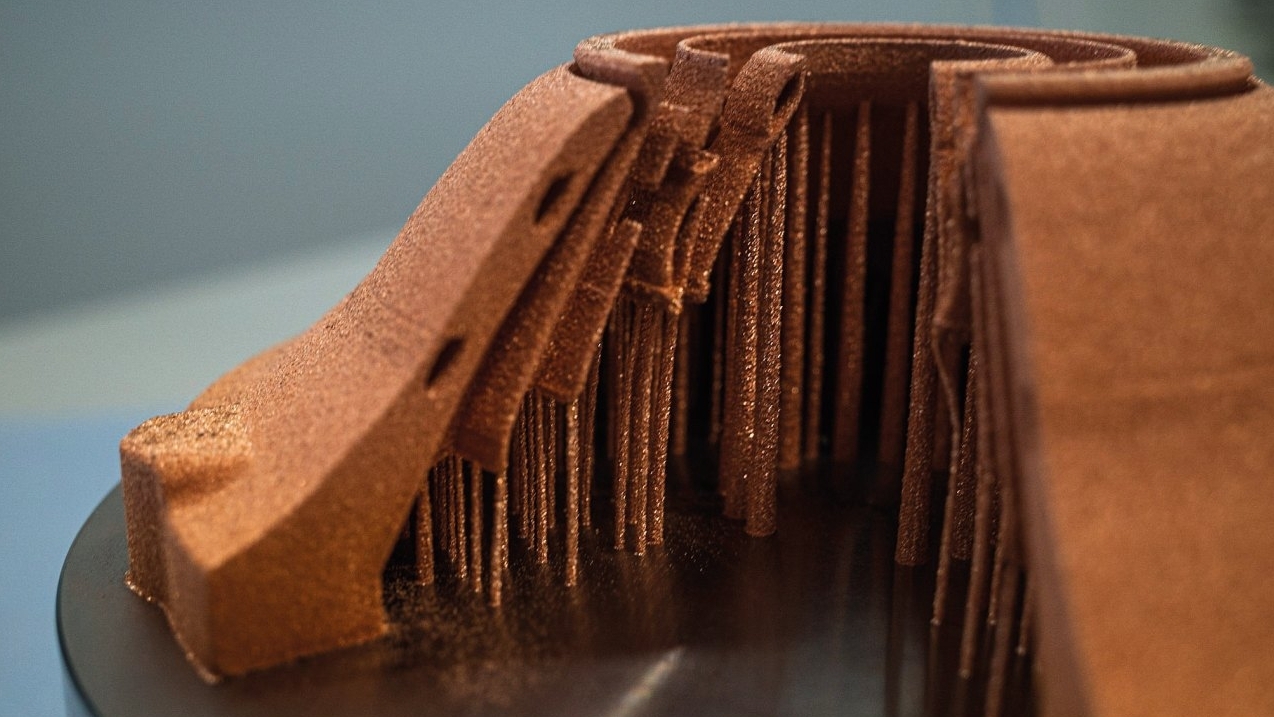

Creating sophisticatedly shaped plastic parts with a 3D printer is no longer an art, but everyday technology. Pure copper is a completely different matter: until now, it has not been possible to completely melt the metal using infrared lasers in order to produce complex components layer by layer. This is why the Fraunhofer Institute for Material and Beam Technology IWS in Dresden is now using a new type of additive manufacturing system that processes the metal with a short-wave green laser with virtually no defects.

The copper powder absorbs more than 70% of the energy used and melts completely, making it suitable for additive manufacturing. This enables new manufacturing approaches that were previously not possible with pure copper. As a result, complex components made of pure copper and copper alloys can be produced for a wide range of applications and the efficiency of electric motors and heat exchangers can be increased.

The new laser beam melting system is unique in Saxony, and there are few comparable systems in Germany. Instead of infrared light with a wavelength of 1064 nanometers, it uses a disk laser with high-energy green light with a wavelength of 515 nanometers. The procurement of the new system for the Fraunhofer IWS was made possible by the "Smart Production and Materials" performance center. This is an association of Chemnitz University of Technology, Dresden University of Technology and the Fraunhofer Institutes IWS, ENAS, IWU and IKTS, all of which are researching innovative production technologies and materials for Industry 4.0. The "TruPrint1000", equipped with a green laser, is now part of the "Additive Manufacturing Center Dresden" (AMCD). Here, IWS experts are working together with colleagues from TU Dresden on further pioneering technologies for additive manufacturing (Fraunhofer IWS Dresden Markus Forytta).