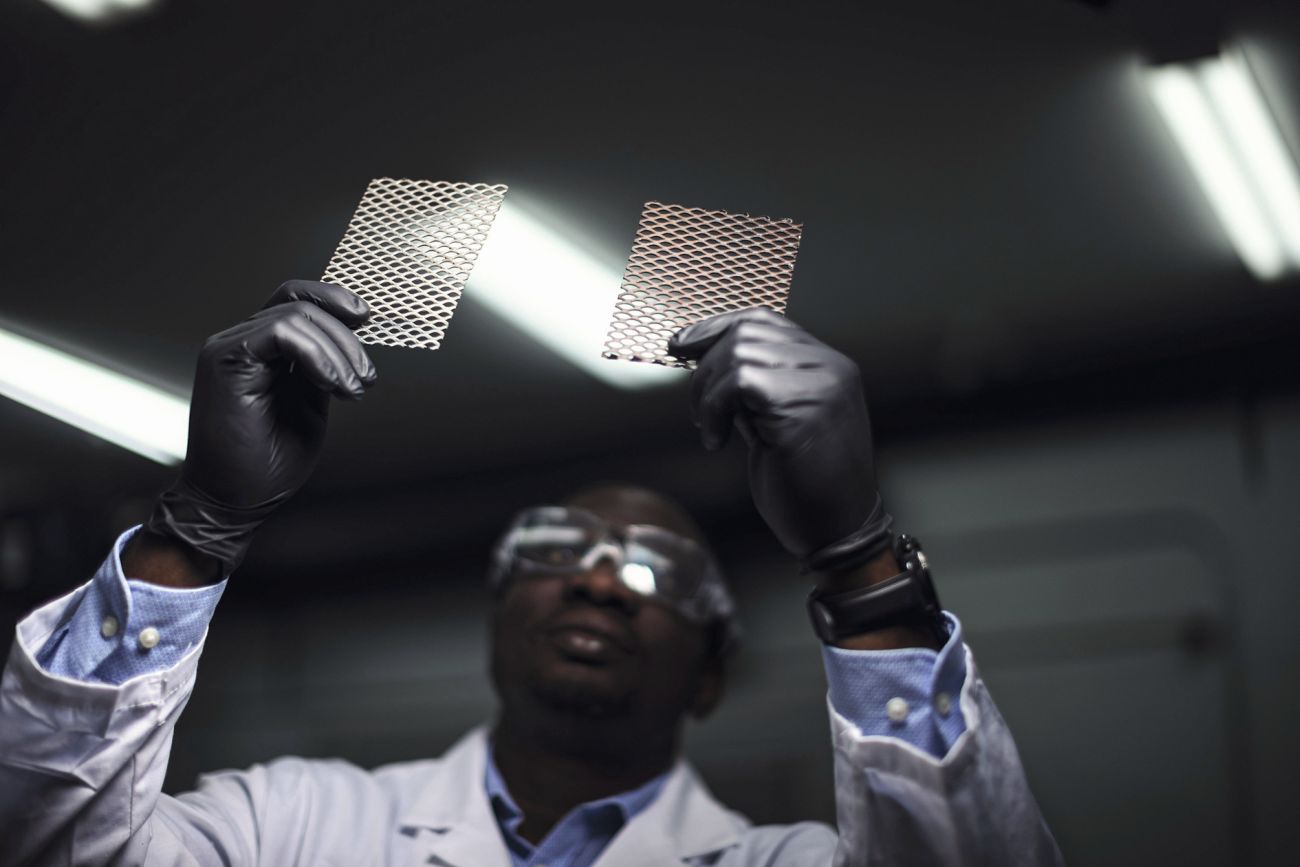

Mixed metal oxide (MMO) anodes contain considerable quantities of valuable precious metals even after their use or at the end of their service life. For example, the price of a troy ounce of iridium has risen by 800 percent since 2015. However, many anode owners and users do not recover these valuable precious metals, missing the opportunity to significantly reduce the overall cost of anodes.

The anodes are used in various areas of electroplating, including: electro-tinning, electrolytic galvanizing, electroplating of metals.

Depending on the condition of the anode substrates, there are two options: Refurbishing enables the recovery of precious metal residues from the MMO anode coating and the return of gently cleaned anode substrates for recoating. The recycling approach includes the recovery of precious metal residues and the tempering of the titanium substrate, which is returned to the material cycle. However, recovery is not only worthwhile in economic terms: recycled precious metals have aCO2 footprint that is reduced by up to 99%, which represents a significant contribution to environmental protection.