As a specialist in surface technology, Plasmatreat offers reliable, efficient and environmentally friendly solutions for the battery industry - from cleaning and activation for long-term stable connections to highly effective functional coatings for reliable corrosion protection. The result: higher battery performance, leaner production processes and lower costs.

The battery is the heart of every electric vehicle. Its performance is crucial to the success of electromobility. The demands placed on manufacturers are correspondingly high, particularly with regard to tightness, ensuring battery thermal management and contact between the individual battery cells. This is where Plasmatreat's innovative plasma technologies are the key to success. Whether intensive ultra-fine cleaning, efficient surface activation or anti-corrosion coating: the inline processes guarantee maximum process stability and help to increase the efficiency of the battery pack and reduce production costs at the same time.

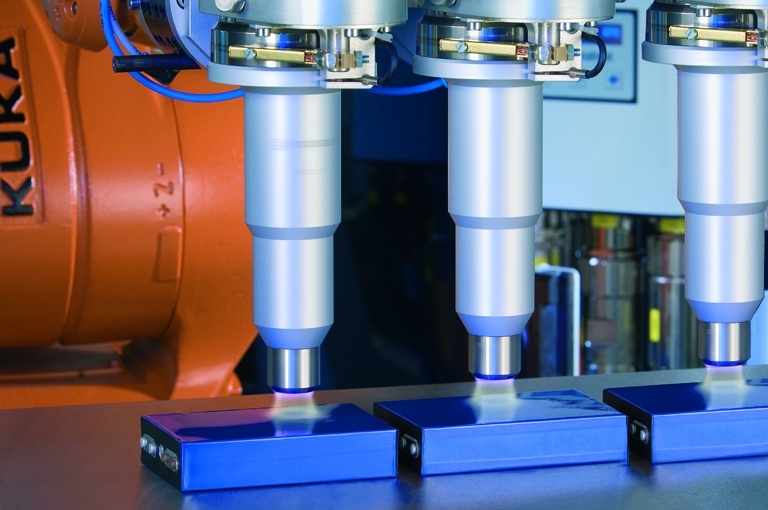

Multi-talented plasma: cleaning, activating, coating

On the way from individual cells to battery modules and packs, Plasmatreat's Openair Plasma® technology is used in a variety of applications. For example, the aluminum surface must be optimally cleaned and activated before the (insulation) bonding of the individual cells to each other so that there are no subsequent failures due to overheated cells over the entire service life. Absolute freedom from particles is also essential for electrical contacting. Plasma treatments also enable an improved adhesive bond when gluing the heat conducting plate under the battery (thermal management) and ensure that the battery housing is completely sealed. Regardless of the type of sealing system (sprayed, bonded or FIPG), aluminum and plastic connections are very susceptible to infiltration due to their different H2O affinity. The plasma polymer nanocoating PlasmaPlus® from Plasmatreat provides highly effective protection. This is applied to the metallic component after cleaning and activation with Openair-Plasma®. This creates a media-tight bond in the subsequent injection molding process. This significantly increases the barrier effect against corrosive electrolytes and at the same time provides extremely high and long-term stable corrosion protection.

High-performance batteries for electromobility

The Openair-Plasma® technology, which is easy to integrate inline, enables an efficient process sequence without separate chamber systems. This makes Openair-Plasma® ideal for fully automated pre-treatment in the production of battery modules and battery packs in large quantities and at high process speeds.

www.plasmatreat.de