By developing release agent-free process and material systems in the OptiBlade joint project, researchers at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM and their partners have succeeded in optimizing rotor blade production for wind turbines and thus significantly reducing their manufacturing costs.

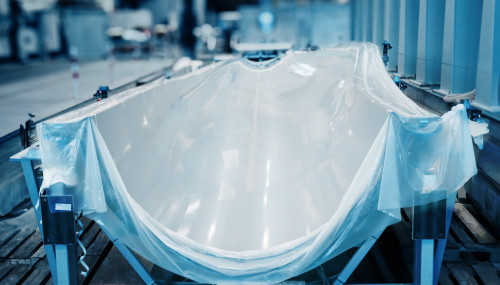

The flexible vacuum stretch-formed PeelPLAS® release film fits like a second skin into the 18 m long rotor blade segment mold and enables release agent-free demolding of the large FRP component after production (Image: Fraunhofer IFAM)

The flexible vacuum stretch-formed PeelPLAS® release film fits like a second skin into the 18 m long rotor blade segment mold and enables release agent-free demolding of the large FRP component after production (Image: Fraunhofer IFAM)

As part of the project, a new low-pressure plasma web processing system was put into operation and plasma processes were developed that can be used to apply an ultra-thin plasma-polymer release layer to film half-tubes up to 2.4 m wide. The resulting flexible, stretchable PeelPLAS release film reaches a width of up to 4.8 m when unfolded. For even wider shapes, this release film can be easily welded. A CFRP rotor blade demonstrator component was used to prove that it can be demolded and immediately processed without the need for release agents. A new type of plasma-coated composite film will later be fixed to the mold as a semi-permanent release film and enable multiple demolding of fiber composite plastic components.