The annual meeting of the International Electrochemical Society (ECS) from October 8-12 in Gothenburg, Sweden, also focused on the post-processing of 3D-printed metal components

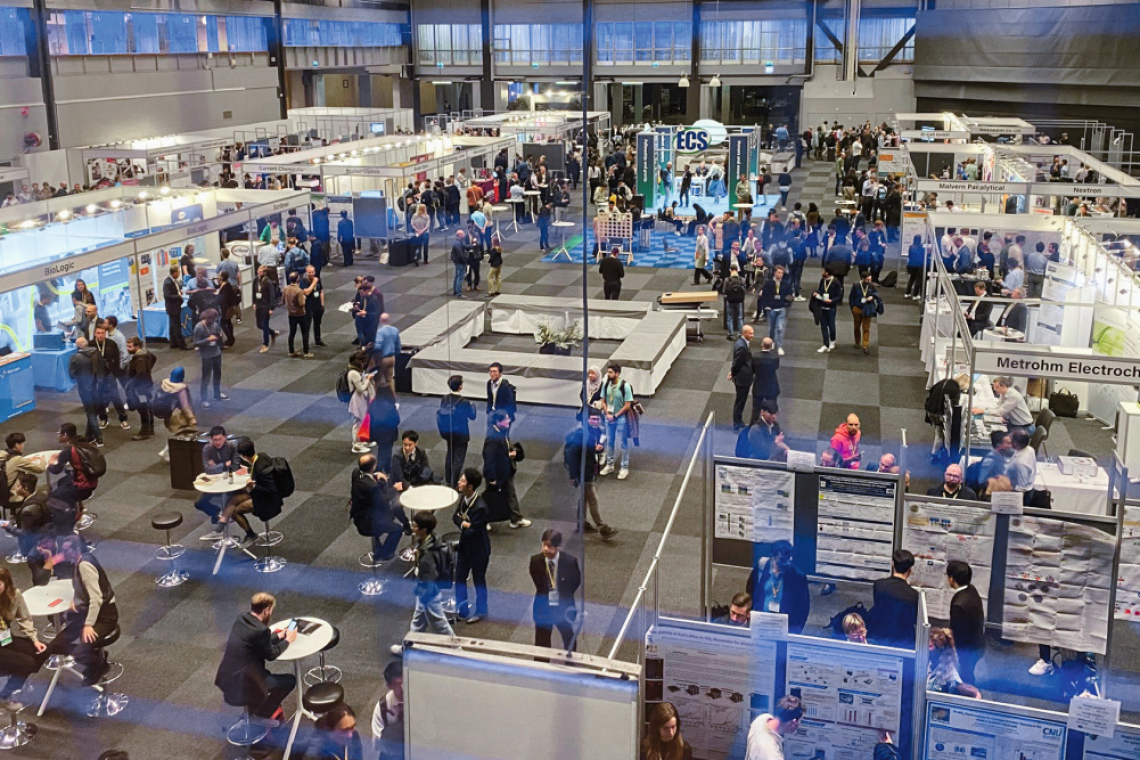

As an international umbrella organization, the ECS brings together electrochemists from all disciplines, but above all not only from academia. As electrochemistry is by no means a dead science, contrary to some prophecies of doom in recent decades, but is in fact the most important approach to solving the problems of our time, around 2,000 scientists from all corners of the world gathered for the annual conference in Gothenburg, Sweden. Gothia Towers, the largest hotel complex in Scandinavia, provided an impressive setting.

With up to two dozen parallel lecture series, the ECS conference shone in its former glory for the first time since the pandemic. It was the first ECS conference in Europe for almost 15 years. The range of topics was as diverse as the participants and ranged from classic topics such as corrosion, galvanic processes, batteries and fuel cells as well as electrochemical synthesis to future topics such as recycling, waste and water treatment and the production of "green" hydrogen via electrolysis. Of course, the post-processing of 3D-printed metal components using electrochemical processes was not to be missed. The latter will be discussed in more detail here.

The first approach to post-processing 3D-printed components was the use of electropolishing.

The first approach to post-processing 3D-printed components was the use of electropolishing. Electropolishing is a proven method that is ideal for smoothing out micro-roughness and can bring surfaces close to a mirror finish. However, the process initially failed due to the sometimes significant surface unevenness of 3D-printed metal components. Possible solutions were the combination with electrochemical (plasma polishing in a second step) or mechanical processes (e.g. subsequent vibratory grinding).

Galvanotechnik editor Dr. Wolfgang Hansal reported on the conference and focused in particular on the post-processing of 3D-printed metal componentsHowever, a new category of electrochemical processes soon emerged from the field of dynamic electrochemistry, which was much better suited to the special processing of AM components. All of these processes, some of which are similar but very different in detail, were presented and discussed in a separate, full-day series of lectures. It was shown that very similar results could be achieved independently of each other in the USA (e.g. Faraday Technology Inc. with Dr. E.J. Taylor or Los Alamos Laboratories with Dr. D. Hooks) and in Europe (e.g. TU Ilmenau with Prof. Bund, Rena/EGM Vienna with Dr. Hansal). Interestingly, the approaches to finding the solutions were very different: while in the USA it was more of a "hands-on" pragmatic approach, in Europe the knowledge-based approach dominated.

Galvanotechnik editor Dr. Wolfgang Hansal reported on the conference and focused in particular on the post-processing of 3D-printed metal componentsHowever, a new category of electrochemical processes soon emerged from the field of dynamic electrochemistry, which was much better suited to the special processing of AM components. All of these processes, some of which are similar but very different in detail, were presented and discussed in a separate, full-day series of lectures. It was shown that very similar results could be achieved independently of each other in the USA (e.g. Faraday Technology Inc. with Dr. E.J. Taylor or Los Alamos Laboratories with Dr. D. Hooks) and in Europe (e.g. TU Ilmenau with Prof. Bund, Rena/EGM Vienna with Dr. Hansal). Interestingly, the approaches to finding the solutions were very different: while in the USA it was more of a "hands-on" pragmatic approach, in Europe the knowledge-based approach dominated.

Europe in particular provided important insights into the behavior of various additively manufactured alloy systems during electrochemical dissolution and leveling. An interesting approach was presented by E.J. Taylor, to whom a separate lecture block was dedicated on the occasion of his retirement. He recognized the limitations of static electropolishing and specifically changed the pulse sequence during treatment. This enabled him to counteract the decreasing (flatter) microprofile on the surface with increasing processing time and achieve a significantly better leveling of the surface. However, the process also depends heavily on the positioning of the counter electrode, which is essential for controlling the field lines during pulsed metal dissolution. In stark contrast to the highly concentrated solutions used in classic electropolishing, highly diluted aqueous salt solutions or diluted sulphuric acid are used as electrolytes in this process. The polishing effect is achieved exclusively through the targeted generation of mass transport conditions via the pulse sequence and not via the electrolyte. Passivating metals are depassivated via reverse pulses.

Different printing methods sometimes require different approaches. Once again, it became very clear in the presentations that a component printed using the powder bed process does not necessarily have the same surface as a component produced using binder jetting. For the latter type of construction, adapted processes are required, appropriately combined with thermal treatment, in order to be able to process such surfaces electrochemically. Pulsed currents are also used here.

The same applies to the chemical-electrochemical process of sheathing, which has its roots in Austria. Here, however, it is not so much the microprofile that forms on the surface that is influenced by the current pulses, but rather the potential field and the local field line density within a secondary current density distribution. In addition to surface leveling, this method is particularly suitable for removing support structures and, in combination with chemical etching and polishing, for processing complex geometries and component interiors.

All in all, the various presentations showed a strong connection to industrial production. The good scalability, the applicability to different alloys and the comparatively low costs are leading to an increasingly broad application of electrochemical methods in the industrial post-processing of additively manufactured metal components.

Although the synergy has not (yet) been recognized by the organizers, there would be overlaps with the lecture blocks on metal recovery and sustainability in electroplating technology in the processing of polishing solutions, in the sense of re-deposition of the dissolved metals. This processing makes little sense for light metals, especially due to the presence of aqueous systems, or even fails due to technical feasibility, but can contribute to more ecologically sustainable production and indirect cost reduction for more precious metals (nickel and above).

Although this is only a small excerpt from a thematically comprehensive conference, the industrial relevance of electrochemical methods in hot areas became very clear. The stronger industrial reference compared to previous ECS conferences gives reason to hope for a rapid implementation of the researched correlations and developed methods in production practice.

Photos: W. Hansal