The Betenio process provides the industry with a method for corrosion protection treatment that has significant advantages over the standard blasting and acid treatment methods on the market. Until now, the systems have been individually designed according to the user's requirements. Rio GmbH now also offers the system technology in two standard versions with defined tank sizes.

The Betenio process is based on the active principles of phosphating and descaling: scale and oxide skin of the component are completely removed. In contrast to previous processes, however, the systems only require a single bath: Degreasing, pickling and phosphating are carried out in a single step. The corrosion-prone surface is converted into a protective iron phosphate layer.

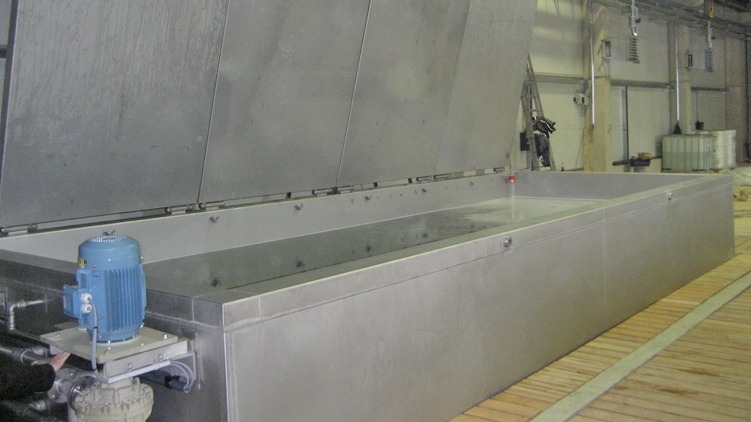

This allows the construction of very compact systems, and investments are reduced by 25 to 30 % compared to conventional acid systems. Energy and costs for rinsing water treatment are also saved.

Both the investment and operating costs are also much lower compared to blasting. The reasons for this are the low personnel costs and the minimal need for consumables.