The basis for high-quality plastic surfaces is the tool steel that creates them. The better this steel can be polished, the better the end result and the fewer rejects.

Uddeholm Tyrax® ESRisa new, corrosion-resistant tool steel with high hardness, developed for applications with extreme demands on surface quality. Applications that require high light transmission are constantly increasing. These include automotive interior lighting and high-quality optical lenses. Multifunctional displays can be found in all areas, from white goods to electronic devices. Autonomous driving cars require the integration of cameras and lidars for safe transportation. These applications all have one thing in common, namely extreme demands on the surface finish.

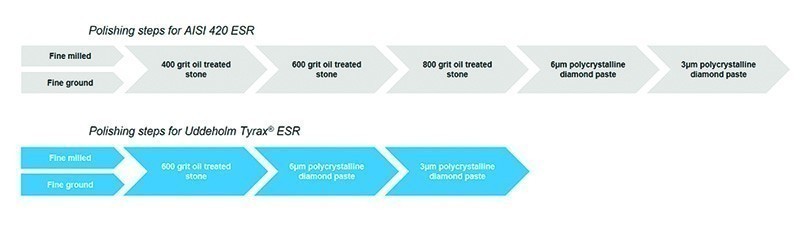

Overview of the polishing steps: Tyrax ESR steel (below) saves work steps compared to conventional steels

Overview of the polishing steps: Tyrax ESR steel (below) saves work steps compared to conventional steels

The molded part is an exact replica of the mold itself, a high-gloss surface finish is required for optimum results. Poor surface finish leads to disastrous, financially costly results. High scrap rates are unacceptable for all parties involved. End customers may not receive their parts on time and the supplier of the affected part suffers expensive downtime. Mold makers know that repolishing is a time-consuming and expensive process. They know they can't afford to do things twice if they want to maintain a strong, competitive market position.

Re-polishing is time consuming and expensive

The surface finish of a mold depends on the polishing technique in combination with the microstructure and cleanliness of the tool steel. Uneven hardness distribution across the surface means uneven material removal during the polishing process, with harder areas resisting abrasion better than softer areas. Uneven hardness can be the result of impurities in the steel and/or segregation.

Avoid contamination of the tool

Two of the most common surface defects are pitting and orange peel:

Pitting looks like scattered pinholes scattered across the surface. Pitting usually occurs when hard particles in the steel, such as carbides or oxides, break out of the surface. The best way

to avoid such problems is to maintain a high purity steel with very fine and evenly distributed carbides.

Pitting can also occur if the mold is stored in a humid environment where corrosion attacks cause very fine holes on the mold surface. In such cases, a corrosion-resistant mold steel is required.

Orange peel means that the surface morphology resembles an orange peel. Deformations on the mold surface cause this phenomenon. The best way to minimize the risk of orange peel is to choose a tool steel with a homogeneous microstructure, such as an ESR grade, in combination with high hardness.

One of these options is Uddeholm Tyrax® ESR. This corrosion-resistant steel grade is easy to polish. In addition, the cleanliness is impressive, almost all impurities have been removed and segregation is minimized. The high hardness of up to 58 HRC prevents the risk of orange peel. The chemical composition of Uddeholm Tyrax® ESR enables the polisher to achieve a high-gloss finish.

The finish is achieved in three polishing steps (compared to five steps for other steel grades), reducing polishing time by 40-50%.

Conclusion:

Uddeholm Tyrax® ESR offers excellent polishability combined with high hardness and corrosion resistance, making it a good choice for applications where surface finish is of utmost importance.

The main advantages of this steel for high-gloss surface coatings are:

- highest cleanliness

- reduced polishing time

- high corrosion resistance