plating electronic develops direct current sources and pulse reverse current sources for electrochemical processes. For a wide variety of applications in electroplating, such as chrome plating processes, anodizing or aluminium dyeing processes, plating electronic has expanded its range of compact water-cooled high-current direct current sources.

The pe5910-W-AFE power station with optional integrated electronic pole inverter and AFE technology sets a new standard with up to 10,000 A at 20 V and a maximum output power of up to 200 kW. Maximum power in the smallest of spaces and with a footprint of just 800 mm × 600 mm (W × D).

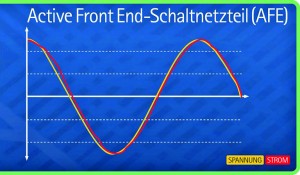

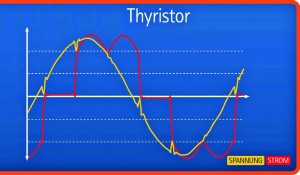

In rectifiers with integrated AFE technology, a sinusoidal current is drawn from the AC supply network with the same phase angle of current and voltage. This leads to a noticeable reduction in harmonic oscillations to below 1 % (THD_I). Rectifiers with AFE technology also achieve an increase in the power factor from the standard 0.95 to 1.00. Another positive side effect of sinusoidal mains current extraction is the reduction of the phase current and therefore a lower load on the supply transformer for the rectifier.

The best possible flexibility, device availability and ease of servicing are always top priorities at plating electronic. This is guaranteed by the use of modular technology.

Thanks to the use of proven switched-mode power supply technology and digital control technology, the DC source is characterized by precise control accuracy and very low residual ripple. Optimized process quality and qualitative advantages in many coating processes are the result.

The high efficiency of 90-96 % means lower energy consumption and therefore savings in operating costs. The very high power factor of up to 0.95 (AFE) enables further energy cost savings due to better power quality and thus reduced reactive power. Additional savings potential is provided by the compact design and the possibility of installing the DC source as close as possible to the bath.

The new design of the DC output is another highlight. Busbars can now be routed to the DC connections in any orientation, enabling flexible and simple integration into systems and therefore shorter busbar routes.

The power range of the DC source can be individually multiplied by parallel or series connection.

Integration and control can be carried out via the familiar interfaces, such as Profibus, Profinet, Modbus, TCP/IP or RS485. An analog interface can be used to ensure communication with older system controls. As an isolated solution, plating electronic also offers manual operation with operating units, which are also suitable for future external connection to the control system.