Surfaces play a key role in valve, measurement and control technology. Gemü therefore manufactures them in-house using electrochemical methods, among other things.

Gemü produces not only in Europe, but also in Asia and North and South AmericaThisyear, Wirtschaftswoche declared the technology company Gemü Gebr. Müller Apparatebau GmbH &Co. KG, headquartered in Ingelfingen-Criesbach, Baden-Württemberg, the world market leader in valve, measurement and control technology for sterile processes for the sixth time in a row. The company has 27 subsidiaries and six production sites in Germany, Switzerland, China, Brazil, France and the USA. For applications in sterile areas such as medicine, pharmacy, biotechnology and food production, high demands are placed on the degree of purity and corrosion resistance of the functional surfaces. Gemü therefore carries out the corresponding surface treatment processes in-house in order to meet these requirements.

Gemü produces not only in Europe, but also in Asia and North and South AmericaThisyear, Wirtschaftswoche declared the technology company Gemü Gebr. Müller Apparatebau GmbH &Co. KG, headquartered in Ingelfingen-Criesbach, Baden-Württemberg, the world market leader in valve, measurement and control technology for sterile processes for the sixth time in a row. The company has 27 subsidiaries and six production sites in Germany, Switzerland, China, Brazil, France and the USA. For applications in sterile areas such as medicine, pharmacy, biotechnology and food production, high demands are placed on the degree of purity and corrosion resistance of the functional surfaces. Gemü therefore carries out the corresponding surface treatment processes in-house in order to meet these requirements.

Mechanical processing

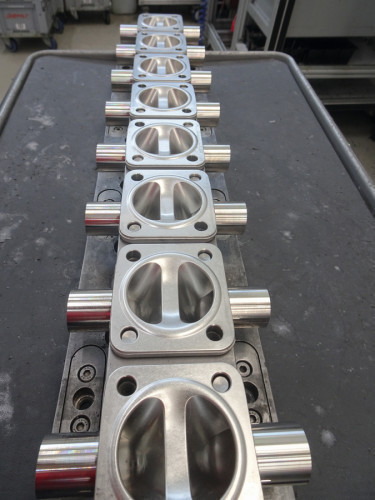

The surfaces of various valve bodies made of high-alloy stainless steels are prepared for subsequent electrochemical treatment using state-of-the-art milling machines and grinding systems. The fully automated and freely programmable electropolishing system enables flexible process sequences with which even complex valve parts can be processed in accordance with customer requirements and the current state of the art. To test and optimize the processes, Gemü uses a workshop in which various tests are carried out. Small series and special designs are also processed here.

For use in sterile areas, the first-class and reproducible quality of the inner surfaces and surfaces in contact with the medium is crucial. These are processed in several steps. First, the inner surfaces of the valve body are geometrically shaped by milling in accordance with the drawing. This is followed by mechanical grinding to achieve the surface condition required for electropolishing. This is checked for roughness and visual appearance. The roughness values (Ra) must be in a range between 0.8 and 0.25 µm. The surfaces must be homogeneous and free of stains and grease.

Electropolishing

The frame plays an extremely important role in successful electropolishing. For this reason, Gemü has developed special frames that enable fully automated processing with the highest surface quality and reproducibility. The flexible design of the frames allows quick changeover for electropolishing of complex valve parts.

Special frames have been developed ...

Special frames have been developed ...

The program sequences of the electropolishing system are defined in accordance with the requirements of ASME-BPE, Gemü factory standard for surfaces and customer order specifications. Various processing steps are coordinated and programmed as a program sequence. The respective programs differ in terms of process steps, treatment times, power supply and other parameters. To protect the surfaces from external influences and prevent corrosion, each processing program is concluded with a passivation step. This additionally reinforces the chromium oxide-rich passive layer created on the stainless steel surface.

By using high-performance electropolishing electrolytes from Anotech GmbH, which have been adapted for the materials and the range of parts, and process chemicals from Swiss company Elpochem AG, Gemü achieves optimum surface leveling, a shiny appearance and high-quality corrosion protection. In the in-house chemistry laboratory, the bath parameters are checked and the processed surfaces are examined microscopically in their initial and final state. Gemü is working on the development of alternative process technologies and process optimizations, which are integrated into the production process with the support of external project partners and suppliers in order to continuously increase efficiency and quality.

Gemü components after machining

Gemü components after machining

Constantly refined processes, the use of selected materials and a focus on industry-specific applications result in high-quality, innovative and application-oriented products, for example for ultrapure water treatment, drug production, food production or beverage filling.

Photos: Gemü