High molecular weight polyethylene (PE 1000) is considered one of the best materials in the electroplating industry for barrel constructions for coating mass-produced parts. PE 1000 is extremely wear-resistant and resistant to abrasion and chemicals. This promises a particularly long service life and availability of the electroplating drums - especially when abrasive workpieces, such as sharp-edged parts, are treated.

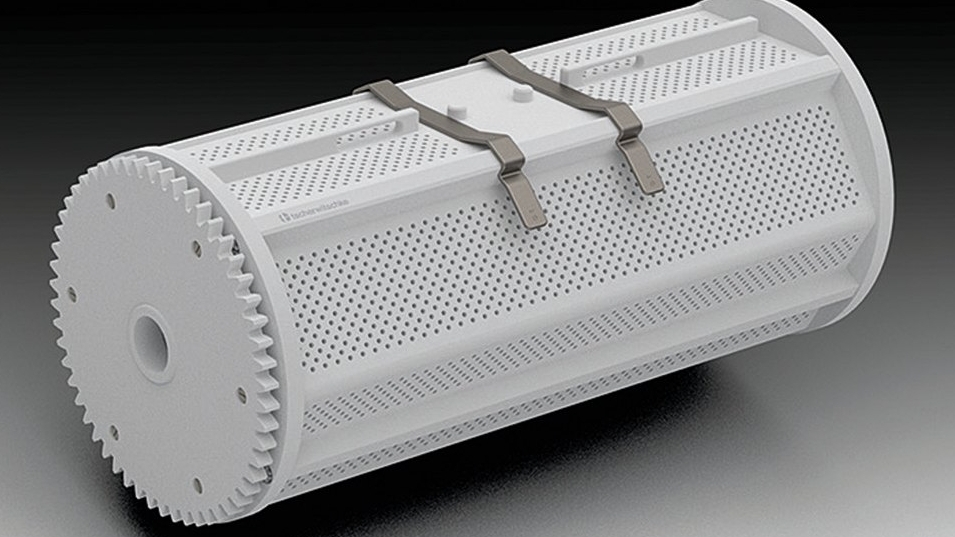

With the GALVA-HP - "HP" stands for "High Performance" - Richard Tscherwitschke GmbH offers a completely new, mechanically butt-welded barrel construction made of PE 1000. Thanks to a new manufacturing process, the number of welded joints has been reduced to a minimum. Improved welding factors and a special welding device guarantee high-quality welded joints. The production process completely dispenses with plug-in connections that could lead to carry-over. This makes the GALVA-HP absolutely gap-free, tear-resistant and particularly suitable for drying goods in the Galvadry drum dryer.

In addition to the high wear resistance and other positive physical properties of the PE 1000 material used, there is a very low tendency for deformation of the perforation holes or the formation of deposits.

By optimizing the drum geometry, it was also possible to increase the volume of the drum and the opening area. This increases the capacity per coating pass and the product can be filled and emptied more quickly and safely.