Umicore Metal Deposition Solutions (MDS) in Schwäbisch Gmünd has developed a silver-graphite dispersion electrolyte for coating connector contacts in high-current applications. These can be used in charging plugs for fast charging electric cars and can withstand 50,000 mating cycles.

The silver dispersion layers deposited with the electrolyte Arguna C-100 prove to be extremely stable even at elevated temperatures. They therefore meet the increased requirements in terms of reliability and durability for connector contacts. This coating therefore has the potential to establish itself as the new standard for high-current applications.

Technical requirements for silver coatings not yet met

The durability of existing connector contacts for transferring high charging power from the power source to the application or battery is not yet satisfactory for manufacturers or suppliers.

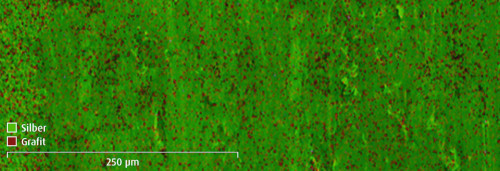

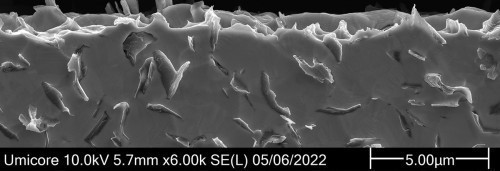

Statistically random distribution and intercalation of the graphite lamellae in the electrolytically deposited silver matrix, shown here using a prepared layer under a scanning electron microscope. The silver matrix was selectively etched back here and the integrated graphite lamellae remain in their position

Statistically random distribution and intercalation of the graphite lamellae in the electrolytically deposited silver matrix, shown here using a prepared layer under a scanning electron microscope. The silver matrix was selectively etched back here and the integrated graphite lamellae remain in their position

Coatings with fine silver are, however, state of the art in terms of electrical and thermal conductivity. The tendency to cold welding in conjunction with a low hardness and a high coefficient of friction leads to rapid wear of the silver layers with frequent mating. In order to achieve the required mating cycles and to minimize wear, additional contact lubrication is therefore applied to the silver surfaces. The accumulation of dirt and dust particles can lead to the formation of corrosive or abrasive foreign layers over time, which can lead to excessive temperatures and a reduction in charging performance. Hard silver coatings (silver alloys) have a significantly higher hardness and show noticeably improved vibration resistance in some applications. However, alloyed metals have a detrimental effect on electrical conductivity and the coefficient of friction is usually close to that of fine silver.

Durable and high-performance silver coatings for such high-current applications are therefore urgently required. In electromobility, a shortened service life of the charging plugs can not only cause enormous costs due to material, time and service costs - the image also suffers. After all, if a permanently installed vehicle inlet of an electric car has to be replaced early and at great expense, or if the charging performance of the charging infrastructure continuously decreases, this often quickly calls into question the reliability and quality of the provider.

Abrasion resistance ensures charging performance

The Arguna C-100 silver-graphite dispersion electrolyte achieves considerable abrasion resistance and therefore reliability and durability of the contact coating and the charging plug thanks to the graphite particles embedded in the silver layer. This is made possible by an optimized graphite component, which is embedded in the silver matrix and serves as a solid lubricant. A new surface is created with each friction process and the abraded tips of the graphite lamellae are distributed over the friction surface. The usual abrasion of the silver surface is prevented, the contact resistance is kept low and thus a continuously high charging performance is guaranteed. Under laboratory conditions, an end-of-life tribometer test proves the low and stable coefficient of friction of the Arguna C-100 coating system.

Contact socket and contact pin for EV charging plugs, coated with the new silver-graphite dispersion electrolyte

Contact socket and contact pin for EV charging plugs, coated with the new silver-graphite dispersion electrolyte

Even after more than 50,000 mating cycles, an intact silver graphite layer can be detected - and cross-compatibility with other mating contact materials (e.g. fine, hard or dispersion silver layers) completes the required functionality in the field. The new electrolyte thus combines and enhances the positive properties of fine and hard silver. On the one hand, the fine silver matrix has excellent electrical conductivity and, on the other, the maintenance-free solid lubrication of the graphite simultaneously increases abrasion resistance and thus reduces wear, even with a high number of mating cycles.

Photos: Umicore