The Lüdenscheid-based company Weinreich manufactures temperature control units for plastics processing and is one of the leading manufacturers in Europe. With the FX series, the owner-managed company now provides customers with an instrument to determine the power requirements in tools and thus make systems more efficient and sustainable.

We have repeatedly received requests from customers to reduce energy consumption not only in large systems, but also in smaller temperature control units by means of variable output," reports Managing Director Guido Schulte and continues: "However, our experience shows that no real savings can be made in the area of temperature control output, i.e. cooling and heating output." This is because the required cooling or heating capacity is defined by the laws of thermodynamics, the component, the shape and many other factors. A change is often at the expense of quality or speed. However, Schulte sees potential in the area of pump performance. "You can save a lot there," he is convinced.

Pump capacity as an energy factor

To explain: The water for temperature control of the tools in plastics processing is constantly circulated and fed through the temperature control channels of the tool at a specified pressure and volume (volume flow). As a rule, the pumps installed in the temperature control units have a fixed drive power, e.g. 1 kW, which ensures a constant pressure. However, this pump output is usually very generously dimensioned and is often set according to the motto "a lot helps a lot". Temperature control units with adjustable pumps are therefore becoming increasingly common on the market. Weinreich does not regulate the pump output in this machine class, as this is very detrimental to the stability of the pumps in the compact systems. The aim of low susceptibility to faults and a long service life is therefore in conflict with regulating the pump output.

The FX series from the Lüdenscheid-based machine manufacturer goes beyond saving energy. It is used to precisely determine power requirements and can also be used for process optimization, regardless of the temperature control unit used. The WTD-FX temperature control unit, equipped with intelligent measurement technology, is suitable for determining the optimum volume flow and pump pressure in the mold, for example. "According to our studies, over 80% of the temperature control units in use are working with a pump output that is too high. This results in a lot of energy consumption, which can easily be saved. However, the necessary volume flow and therefore the performance of the circulation pump must be determined precisely. This is only possible with reliable values," says Schulte. Once the really necessary pump performance has been determined with the FX, a lot of energy can be saved by replacing the pumps of existing appliances. "For one unit, that can quickly add up to over 4,000 kWh per year," says Guido Schulte.

With the FX series, the pump performance actually required can be determined either via the preselectable water pressure or the adjustable volume flow. This value can be used to select a perfectly suitable temperature control unit or, if necessary, to retrofit it.

The device that is finally selected does not require any regulation of the pump capacity, is significantly more robust in operation and cheaper to purchase than adjustable units.

Measurement technology - #from practice for practice

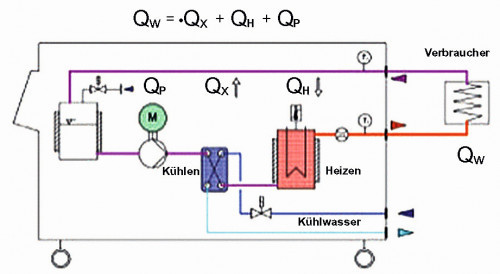

The FX series uses several measured variables to determine the optimum operating point of the mold: The thermal heating or cooling energy converted in the consumer is measured, displayed and compared with the volume flow. When the optimum volume flow is reached, the maximum cooling and/or heating output can be determined by gradually adjusting the cycle times. The function of the FX series therefore goes far beyond the task of a conventional temperature control unit, even if it can be fully used as such.

"Its use is worthwhile from a number of temperature control units of ten, as different temperature control units with different pump drives are often in use here. You can quickly save a lot by swapping them around in a company without any real investment," argues Guido Schulte.

Thermodynamic measurement possible

Another important function is the measurement of the amount of thermal heat to be dissipated. Here, the heating and cooling function in the appliance is switched off for a pre-selectable period of time (10 sec. - 15 min.), providing precise information on the amount of thermal heat to be dissipated during the pre-selected time via the internal heat quantity measurement. For a highly accurate value, the user only has to subtract 1/3 of the pump drive power as friction energy.

In addition to the robust industrial design, the basic equipment of the new FX series includes a highly efficient, frequency-controlled pump with magnetic coupling and a Siemens S7 controller with touch panel for intuitive operation and visualization of the process parameters.

Two device sizes up to 2 kW pump drive power are currently available, although the series is already being planned for larger systems due to the high demand. The machine can be connected either via the on-board Profinet, OPC UA with Euromap 82.1 or analog interface. It is also possible to control the flow, return or differential temperature as well as the volume flow or flow pressure. Further interfaces such as Profibus, Modbus/RS485 or TTY 0-20mA are optionally available.

An optional extension module with USB interface is available for process data recording and export. The compact FX devices can be used for a wide range of applications in the company - from toolmaking to maintenance.