Physicists at the University of Duisburg Essen UDE have found a method of producing two different 2D materials, such as hexagonal boron nitride (hBN) and borophene, using a single process gas. One method for this is chemical vapor deposition (CVD). In this process, the gaseous process gas borazine is passed over an iridium single crystal as a source of boron and nitrogen. There, the gas decomposes and forms new structures on the iridium surface at high temperatures.

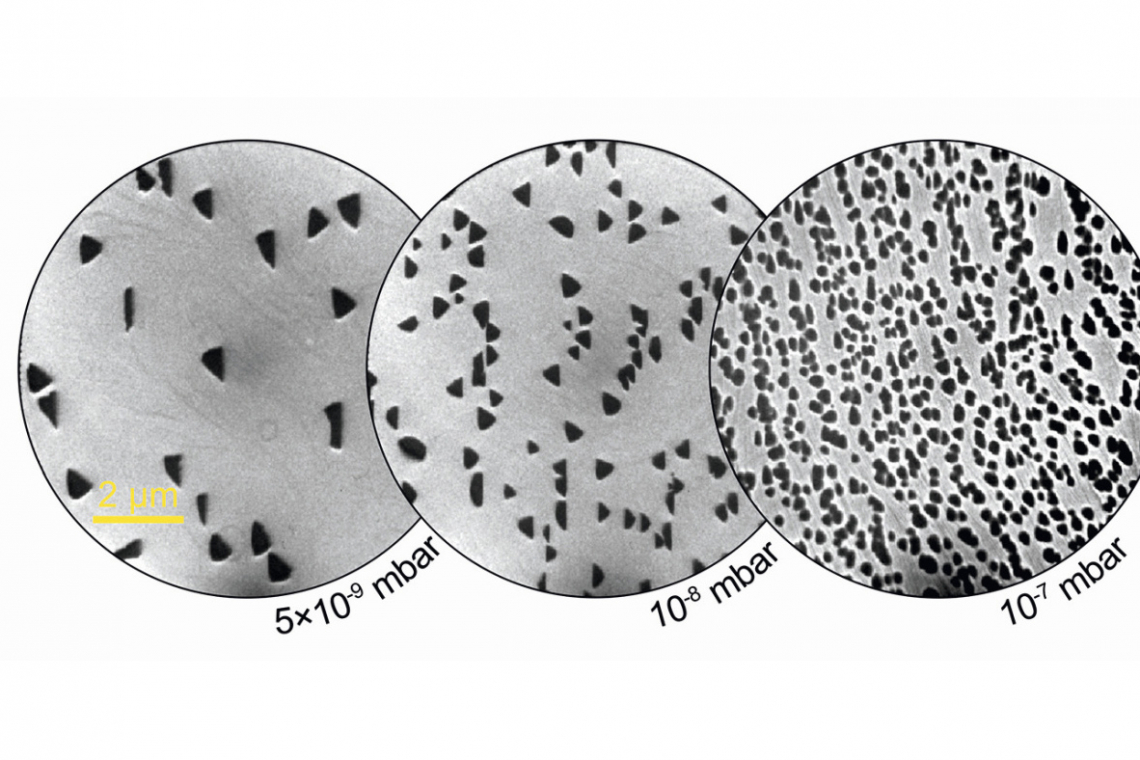

Depending on the temperature, either hBN (800 °C) or borophene (from around 950 °C) is formed, a lattice structure consisting of a single atomic layer of boron, similar to graphene. The pressure applied also influences the growth of the material: if the pressure is too low, no coherent layer forms on the iridium; if the pressure is too high, too many individual islands form, which grow together irregularly and reduce the material quality.

The team succeeded in identifying the pressure and temperature parameters that lead to a high-quality, closed layer. Depending on the process parameters, hBN or borophene can be formed. There is still no efficient method for separating the material from the expensive iridium crystal, but the results can be transferred to CVD processes with other, more cost-effective substrates that could be etched away, for example.