After the ZVO Surface Treatment Days 2020 had to be canceled due to corona, the annual congress will return to Berlin on 23 and 24 September 2021, for the first time as a hybrid event with a correspondingly adapted program.

The treatment of surfaces is a key technology for solving current technical, scientific, economic and ecological problems in the development of innovative products. The ZVO Surface Days, which take place annually in September, make an important contribution to this.

Due to corona-related requirements, capacity restrictions and the associated room concepts, the number of lectures at the ZVO Surface Days 2021 had to be adjusted. The event is planned as a hybrid congress with a presence industry exhibition, limited presence tickets and unlimited online tickets.

Comprehensive health concept

Attendees in Berlin must comply with a strict safety concept: Admission to the event will be granted to persons with full Covid-19 vaccination protection (proof required), persons who have recovered from a Covid-19 infection (proof required) or persons with a negative Covid-19 antigen rapid test not older than 24 hours. A test center is available at the ECC Estrel for daily testing. All participants can be tested free of charge. Prior registration is required for testing. For this purpose, a separate link will be created exclusively for the ZVO Surface Days 2021 Hybrid Edition. It is possible to book an appointment in advance of the event. As the congress starts at 8:00 a.m. on September 23, the rapid tests should be booked and carried out in the afternoon/evening of the day before.

A positive rapid antigen test will result in the immediate isolation of the person tested. The person tested positive must have a confirmation test carried out by means of PCR retesting.

Persons with Covid-19 symptoms may not enter the event.

A medical face mask must be worn in all movement zones in the congress and exhibition area of the ZVO Surface Days 2021 Hybrid Edition. Medical masks are surgical masks or virus-filtering masks of the standards FFP2, KN95, N95 or comparable masks. It is not necessary to wear a face mask as soon as the participant has taken a seat in the lecture hall. If the participant leaves their seat, the face mask must be worn again.

Added value for online participants

The three-day parallel lecture program with 49 lectures will be presented live in three lecture halls. The maximum number of people in the lecture halls remains the same. All three lecture sessions will be broadcast in parallel rooms and - for online ticket holders - streamed live. The plan is not only to stream the pure presentation view of the respective notebook, but also to transmit the live atmosphere in the lecture room using at least one live camera per lecture hall. Although this involves a great deal of technical effort, it offers online participants significant added value. Only corona-compliant seating will be available in the lecture halls; standing room is prohibited.

40 companies have registered for the industrial exhibition. Registrations for the industrial exhibition are no longer possible. The presence program has now been expanded to include a Meet & Greet on Wednesday evening, 22 September 2021. It will take place from 6 p.m. to 10 p.m. in the Estrel's own Waterfront beer garden, or in the spacious atrium of the Estrel Berlin in case of bad weather. The registration deadline for attendance is September 16, 2021.

Airtec Mueku GmbH: The new 4 in 1 solution

EVO Scrubber with 50,000 m3/h and 550 kW heat recovery capacity, horizontal design

EVO Scrubber with 50,000 m3/h and 550 kW heat recovery capacity, horizontal design

EVO Scrubber with 70 000 m3/h and 725 kW heat recovery capacity, vertical design The first exhaust air scrubber with a fully integrated heat recovery module is 20 % more efficient than a conventional heat recovery system using a gas/water heat exchanger. Available in horizontal (horizontal) and vertical (upright) design. By simply returning the condensate from the heat recovery system, the EVO Scrubber's fresh water requirement is reduced.

EVO Scrubber with 70 000 m3/h and 725 kW heat recovery capacity, vertical design The first exhaust air scrubber with a fully integrated heat recovery module is 20 % more efficient than a conventional heat recovery system using a gas/water heat exchanger. Available in horizontal (horizontal) and vertical (upright) design. By simply returning the condensate from the heat recovery system, the EVO Scrubber's fresh water requirement is reduced.

Several heat recovery stages can be integrated, for example to incorporate additional heat sources or to implement summer cooling operation with the aid of a heat pump. In addition, an evaporation stage can be connected upstream, which reduces the amount of waste water by evaporating water, for example from the dirty sink. Electrolyte cooling (e.g. Cr(VI)) can be implemented at the same time.

In the EVO Scrubber, it is possible for the first time to combine all the advantageous functions of an exhaust air system in a single unit and minimize the space required. The design is modular and can be adapted to the respective customer requirements.

Summary of the advantages:

- Evaporation stage: Waste water evaporation

- Evaporation stage: Electrolyte cooling

- Exhaust air purification: Undercutting the TA-Luft by a factor of ten

- Heat recovery: as KVS or additionally via heat pump

MKV GmbH: System manufacturer from Franconia

MKV GmbH, founded in 1992 by Reiner Thoma and based in Allersberg near Nuremberg, designs, manufactures and installs electroplating, crack detection and special systems with 80 qualified employees. MKV GmbH's portfolio also includes the conversion of existing systems, regardless of whether they are our own or third-party products. Comprehensive service and maintenance services as well as a fast supply of spare parts ensure that customers can use their systems for many years to come.

The experience gained in the years since the company was founded comes from many successfully completed projects and almost 30 years of experience of leading employees in electroplating technology. Today, MKV GmbH has extensive knowledge of the manufacture of a wide variety of electroplating equipment: systems for the treatment and testing of aeronautical components, including the special equipment required for this, chemical treatment systems, conventional multi-line systems for electroplating metals or for electroplating plastics.

For example, various systems for the treatment of aerospace components, e.g. by cleaning, descaling and nickel plating, have been manufactured for well-known OEMs in the aerospace industry, which meet the high quality requirements. The machines for the non-destructive testing of aeronautical components (crack detection / FPI) also meet high requirements. The flexibility and quality of MKV GmbH is also demonstrated by the fact that plant operators in this sector always expect customized special solutions, which the plant manufacturer from Allersberg is always ready to provide.

Depending on the task at hand, MKV GmbH is able to deploy specialist personnel with the appropriate specialization. In order to maintain the high quality standard, the specialist staff are constantly trained and all production areas are subjected to regular, detailed quality checks before delivery and assembly. The company maintains a quality management system in accordance with DIN EN ISO 9001:2015

With the move into the new company building in 2016, an area of more than 5000 square meters offers the best possibilities for the production and pre-assembly of systems of almost any size. This step reflects the philosophy of a high level of in-house vertical integration.

All systems are assembled and serviced worldwide by our own specialist staff.

Munk GmbH: Exhibitor at the ZVO annual conference

Rectifiers in all available technologies have formed the DNA of Munk GmbH for over 50 years, be it the classic devices of the ECO series with variable transformers, the electronic devices with thyristors or the PSP Family switching power supplies with air or water cooling.

The latest energy-saving technologies and the further development of proven technology are just a few examples of how the interests of the economy are in harmony with environmental concerns. Munk rectifier systems are not only state of the art, but also set new standards in terms of solidity and efficiency.

Always a large selection of rectifiers also available from stock

Always a large selection of rectifiers also available from stock

In order to leave an ecological footprint, the responsible use of resources is essential and of great importance. The long service life of Munk rectifiers ensures that coating systems retain their value. In particular, the nature of the new gamma L3+ module conserves resources, saves high energy costs and is therefore the basic prerequisite for long-term sustainability.

The new, energy-efficient rectifier design presented at the ZVO Surface Treatment Days represents a new dimension in rectifier technology. Thanks to innovative semiconductors, coupled with sophisticated circuit technology and the same size of plug-in units, a higher degree of efficiency is guaranteed. As a result, the higher power density and the increase in energy efficiency ensure that these new rectifier plug-in units can be integrated into existing systems and CO2 emissions can be reduced.

The modular concept of the Munk rectifier units enables improved statistical reliability thanks to the reduced number of rectifier plug-in units and the resulting reduction in components. This reduces the burden on maintenance and increases operational reliability.

See for yourself when you visit Munk GmbH's stand no. 41 at the ZVO Surface Technology Days in Berlin from September 22-24, 2021.

plating electronic: Perfect currents for demanding grids

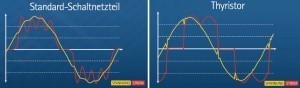

Fig. 1: Current and voltage distortion with passive rectification - typical curvesTheoccurrence of harmonics in AC supply networks has been known for years and has already been the subject of many publications. Recently, however, this topic has increasingly come into focus, as the effects of harmonics in electrical supply networks have a noticeable impact on the manufacturing industry, for example. In industrial networks in particular, harmonics can lead to the failure of electrical consumers and thus to an impairment of the process. Harmonics are also present in industrial grids, but they are often not recognized as critical. Harmonics are caused by the use of non-linear loads in modern production processes. These include, for example

Fig. 1: Current and voltage distortion with passive rectification - typical curvesTheoccurrence of harmonics in AC supply networks has been known for years and has already been the subject of many publications. Recently, however, this topic has increasingly come into focus, as the effects of harmonics in electrical supply networks have a noticeable impact on the manufacturing industry, for example. In industrial networks in particular, harmonics can lead to the failure of electrical consumers and thus to an impairment of the process. Harmonics are also present in industrial grids, but they are often not recognized as critical. Harmonics are caused by the use of non-linear loads in modern production processes. These include, for example

- Frequency converters for electrical drives

- Switch-mode power supplies for lighting (LED/energy-saving lamps)

- Battery charging systems

- IT systems etc.

The use of non-linear loads brings tangible benefits for the user. The high electrical efficiency combined with low energy consumption are particularly noteworthy here. Further advantages of using rectifiers with switching power supply technology are the low residual ripple and high control accuracy. However, the use of these non-linear loads leads to a distortion of the ideal, sinusoidal mains current or voltage.

Harmonics in connection with (galvanic) rectifiers

In principle, switching power supply or thyristor-based rectifiers with passive rectification generate harmonic currents. These lead to a non-sinusoidal current draw (distortion) which can be measured as mains feedback.

Parameters for assessing the grid quality

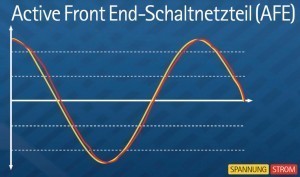

Fig. 2: Current and voltage distortion with active rectification - typical curves In practice, the total harmonic distortion of the current (THDI) or voltage (THDU) is used to assess the quality of a supply network.

Fig. 2: Current and voltage distortion with active rectification - typical curves In practice, the total harmonic distortion of the current (THDI) or voltage (THDU) is used to assess the quality of a supply network.

All harmonic currents generated in a network must flow through the existing impedances and all other parallel branches, which leads to non-linear voltage drops at the impedances. The resulting harmonic voltages spread across the entire network and affect the quality of the supply voltage to other devices. As a result, the harmonic distortion of the current is a cause of the voltage distortion.

Technical measures to compensate for harmonics

Conventional harmonic filters are installed close to the load and generate a compensating current to reduce harmonics in an electrical supply system. Overall, harmonic filters reduce system efficiency due to the additional voltage drop across the filter.

Another alternative for reducing harmonics in an electronic supply network is the use of loads with active rectification, so-called Active Front End (AFE) technology. These loads behave like a resistive load in the electrical supply system, i.e. the current draw is sinusoidal.

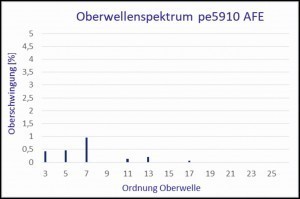

Fig. 3: Harmonic spectrum POWER STATION pe5910 - AFE at 200 kW DC powerWiththe Power Station pe5910 - AFE rectifier cabinet, a rectifier with active rectification with 230 kW DC or 10,000 A is now available on the market for the first time. The integrated AFE technology in the rectifier leads to a significant reduction in current harmonics and an improvement in efficiency. Users benefit from the following advantages when using rectifiers with AFE technology:

Fig. 3: Harmonic spectrum POWER STATION pe5910 - AFE at 200 kW DC powerWiththe Power Station pe5910 - AFE rectifier cabinet, a rectifier with active rectification with 230 kW DC or 10,000 A is now available on the market for the first time. The integrated AFE technology in the rectifier leads to a significant reduction in current harmonics and an improvement in efficiency. Users benefit from the following advantages when using rectifiers with AFE technology:

- Sinusoidal current draw prevents voltage distortion, no harmonic compensation required for rectifier operation

- Increase in the power factor from 0.95 to 1.00

- THDI reduction to less than 3

- Reduced phase current due to sinusoidal current drain, i.e.

- Lower load on the supply transformer

- Reduced transformer dimensioning for rectifier operation

- high efficiency of up to 96 % thanks to active rectification (AFE technology).

Sager + Mack: Smart filter stations for smart customers

The German family-owned company Sager + Mack is the top supplier of pump and filter systems for the electroplating industry. With a vertical range of manufacture of over 97%, the company has been producing specifically for the requirements of electroplating technology in Germany for over 30 years. With a large number of innovative developments, the long-established company ensures maximum productivity for its customers. Sager + Mack is the ideal partner if you want to achieve outstanding quality in the electroplating process. The customer receives state-of-the-art pumps that are reliable and particularly durable. All pumps are made of corrosion and wear-resistant materials and are available in horizontal and vertical versions.

The German family-owned company Sager + Mack is the top supplier of pump and filter systems for the electroplating industry. With a vertical range of manufacture of over 97%, the company has been producing specifically for the requirements of electroplating technology in Germany for over 30 years. With a large number of innovative developments, the long-established company ensures maximum productivity for its customers. Sager + Mack is the ideal partner if you want to achieve outstanding quality in the electroplating process. The customer receives state-of-the-art pumps that are reliable and particularly durable. All pumps are made of corrosion and wear-resistant materials and are available in horizontal and vertical versions.

They are also hermetically sealed, as all parts in contact with the medium are made from solid material. The range of Sager + Mack magnetic drive centrifugal pumps extends from 0.09 kW to 9.2 kW. The pumping of the purest or highly aggressive substances is possible. The filter systems are characterized above all by their user-friendliness and efficiency. The ergonomic hinged star handles allow the cover to be opened and closed quickly without the operator coming into contact with the medium to be cleaned.

All filter housings can be combined with the pumps to form modular filter stations. Sager + Mack offers optional plate, bag or cartridge filters. The plate filter technology is patented and therefore unique on the market. The plates have a flow-optimized design. All filter stations can be equipped with SMART to monitor important indicators such as flow rate, temperature and pressure and to retrieve them continuously from anywhere. Customers can plan their maintenance better and avoid unplanned system downtime. They can also use their filter media more effectively with the help of SMART equipment. The P-Cloud® provides them with fast and reliable remote diagnostics directly from the manufacturer.

This can be called up on a tablet, smartphone or desktop. Customers determine the desired result, Sager + Mack designs the details. Customers do not just purchase products here, but complete solutions tailored to their needs. To ensure consistently high quality, the company is ISO-certified in accordance with DIN EN 9001:2015.

Serfilco: On course for success with new developments

Industrial equipment supplier Serfilco has successfully completed a broad-based modernization and innovation offensive with a series of new filter technology launches and an expansion of its extensive pump range. With the introduction of the HM, JM and FM filter series (capacities from 5m./h to 35m./h), Serfilco has already successfully responded to the requirements of customers in Europe. The new KJM tank series, made entirely of PVDF, can be used on hot baths. Complete systems that are pre-assembled ready for connection are then fitted with one of Serfilco's proven PVDF pumps. The newly developed PPBM bag filter tank offers three different connection types and thus provides more flexibility in planning and installation, especially for conversion and modernization projects.

Serfilco customers in the D/A/CH region are supported by the branch in Monschau near Aachen. "After overcoming the initial Brexit turbulence and winning well-known new customers during the coronavirus pandemic, we see our chosen path confirmed," says Walter Masur, Head of Marketing and Sales.

Hillebrand Group: Corrosion protection as top performance

The WHW Hillebrand Group has been one of the most important companies for cathodic corrosion protection for more than 80 years and is one of the most efficient contract coating companies for zinc, zinc alloy coatings and duplex coatings in Europe. Corrosion protection, functionalities, technically outstanding appearance and the shortest possible throughput times - this is what characterizes the production results of the WHW Hillebrand Group. More than 700 employees at four locations produce directly or indirectly for all well-known automobile manufacturers and other industries.