Wind turbines on the high seas are an alternative to generating wind energy on land - however, generating offshore energy is currently still significantly more expensive than on land. This is also due to the higher maintenance costs. In particular, inspecting the metal anchors on the seabed, the so-called foundation structures, is time-consuming and dangerous. Technicians and materials have to be transported to the plant by ship for maintenance. Transportation and the necessary underwater operations require suitable weather conditions, which only exist on a few days a year. In addition, the costs for ship rental and diving operations are very high.

Fraunhofer IKTS has therefore developed the sensor collar, a measuring system that is permanently installed on the foundation structure of offshore turbines and monitors them continuously. This reduces the need for cost-intensive on-site operations and ultimately the maintenance costs. The sensor sleeve is attached like a ring directly and permanently to highly stressed areas of foundation structures, such as weld seams. This means that biomaterial growing from the outside has hardly any influence on the measurements and the laborious and time-consuming manual cleaning of the measuring points by divers is no longer necessary.

Ultrasonic transducers are integrated into the monitoring system, which act alternately as sensors or actuators. As the ultrasonic waves propagate through the object being monitored, material damage causes

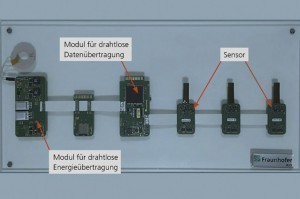

scattering and reflections. These can be used by the integrated signal processing to identify damage such as weld cracks. In addition to biomaterial, the corrosive salt water and the enormous forces of the waves also place a strain on the measuring systems. In order to be able to work permanently under water, the sensor sleeve must be able to withstand the harsh environmental conditions. The sensors are therefore laminated in and reliably protected from seawater ingress by barrier layers. This requires specially developed flat electronic components.

The power supply for the piezoceramic transducers and the readout of the measured data on the monitoring system are no longer carried out by divers, but by remote operating vehicles (ROV) - underwater robots controlled remotely by cable. Using suitable wireless near-field communication, the data is transferred from the sensor cuff to the diagnostic device on the robot and then via cable to the technicians on the ship. This new technology completely eliminates the need for plug connections on the measuring system, which in turn makes a decisive contribution to the long-term reliable operation of the system at sea.