A completely new recycling method to automatically disassemble electronics and recover valuable materials from them - this is the aim of the EU project "ADIR - Next generation urban mining - Automated disassembly, separation and recovery of valuable materials from electronic equipment". Over the course of four years, the Fraunhofer Institute for Laser Technology ILT in Aachen and eight project partners from three countries developed a viable recycling concept. The strategic aim of the ADIR partners was to reduce the EU's dependence on resources and costly material imports and to demonstrate new technologies for inverse production.

The recycling concept focuses in particular on the elements tantalum, neodymium, tungsten, cobalt and gallium. These metals are found in almost all electronics today. They are valuable materials in the truest sense of the word, as they are rare, now cost almost 250 euros per kilogram in some cases and have so far been virtually impossible to recycle economically from used electronics. The ADIR project consortium presented the efficient operation of the recycling concept at the Berlin Recycling and Secondary Raw Materials Conference from March 2 to 3, 2020 and the Mineral Recycling Forum from March 10 to 11, 2020 in Aachen using around 1,000 dismantled cell phones and over 800 circuit boards.

Inspired by urban mining

This is where "urban mining" comes into play, which recovers secondary raw materials from buildings, infrastructure or products. Prof. Reinhard Noll and Dr. Cord Fricke-Begemann from Fraunhofer ILT were inspired by this trend to develop a new recycling approach: Together with the ADIR project partners, they developed a concept for processing typical printed circuit boards from computers and for discarded cell phones. They were supported in their R&D work on robotics by the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg.

Laser takes on leading role

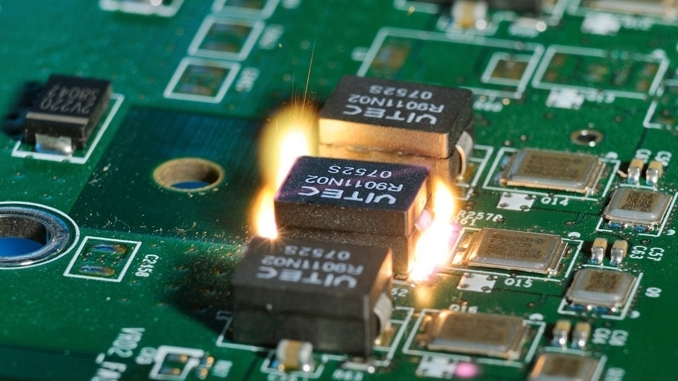

The focus is on flexible processes that can be automated and used to dismantle electronic devices into their individual parts at the end of their useful life. Laser technology, robotics, vision systems and information technology work together intelligently in a disassembly system. Lasers play a key role here, as they can identify ingredients and desolder or cut out components without contact. This makes it possible to efficiently recycle strategically important materials with high economic significance on an industrial scale.

Positive response motivates project partners

The response from the specialist audience at numerous events was very positive. After the project ended in March 2020, this included participants at the Berlin Recycling and Secondary Raw Materials Conference and the Mineral Recycling Forum in Aachen. "There was a great deal of interest from the experts," reports project manager Fricke-Begemann. "This positive response also motivated the project partners from industry." One of them is Electrocycling GmbH from Goslar, which has been testing the ADIR process in field tests and validating it for industrial use since the end of 2018. It used a demonstrator to prove that, for example, by combining the various techniques, considerable quantities of tiny capacitors can be picked out of the electronics in order to recover valuable tantalum from them. This task was undertaken by H.C. Starck Tantalum & Niobium GmbH, which also participated in the ADIR project.

High recycling rate for tantalum

"In the project, we dismantled around 1000 cell phones and over 800 large computer circuit boards, from which we obtained several kilograms of components for further recycling," explains the project manager, "96 to 98 percent of tantalum could be recovered." The example shows that many of the important recyclable materials contained in electronics can be efficiently extracted as desired - in a new type of secondary raw material with a high recyclable material content that is significantly higher than the tantalum ore concentrates from raw material suppliers, for example.

Database helps with automation

The pre-competitive research project has now been completed and the ADIR team has proven its economic feasibility with the demonstrator. "Thanks to the knowledge gained, part of the process chain can now be implemented," says Prof. Noll. "This includes the inspection of the printed circuit boards as well as the desoldering and removal of the components." However, there is still room for improvement, for example in automation, which could speed up the processes. The first experiences with the automatic opening and dismantling of cell phones, which were collected in a database, also contribute to this. Employees can use this data to train a recycling machine on new cell phone models.

These arguments have been well received in the industry and the first partners for implementation have already been found, with more still being sought. But it is not only the more efficient use of raw materials that speaks for the concept: in Germany, dependence on raw material supplies from other regions would decrease and new opportunities would arise for inverse production technologies to close material cycles.

The ADIR project partners at the end of the project:

- Fraunhofer Institute for Laser Technology ILT, Aachen (project coordination)

- Aurubis AG, Hamburg

- Electrocycling GmbH, Goslar

- Fraunhofer Institute for Factory Operation and Automation IFF, Magdeburg

- H.C. Starck Tantalum and Niobium GmbH, Goslar

- Instytut Metali Nieżelaznych, Gliwice, Poland

- Laser Analytical Systems & Automation GmbH, Aachen, Germany

- OSAI A.S. S.p.A., Parella, Italy

- Tre Tau Engineering s.r.l., Turin, Italy.