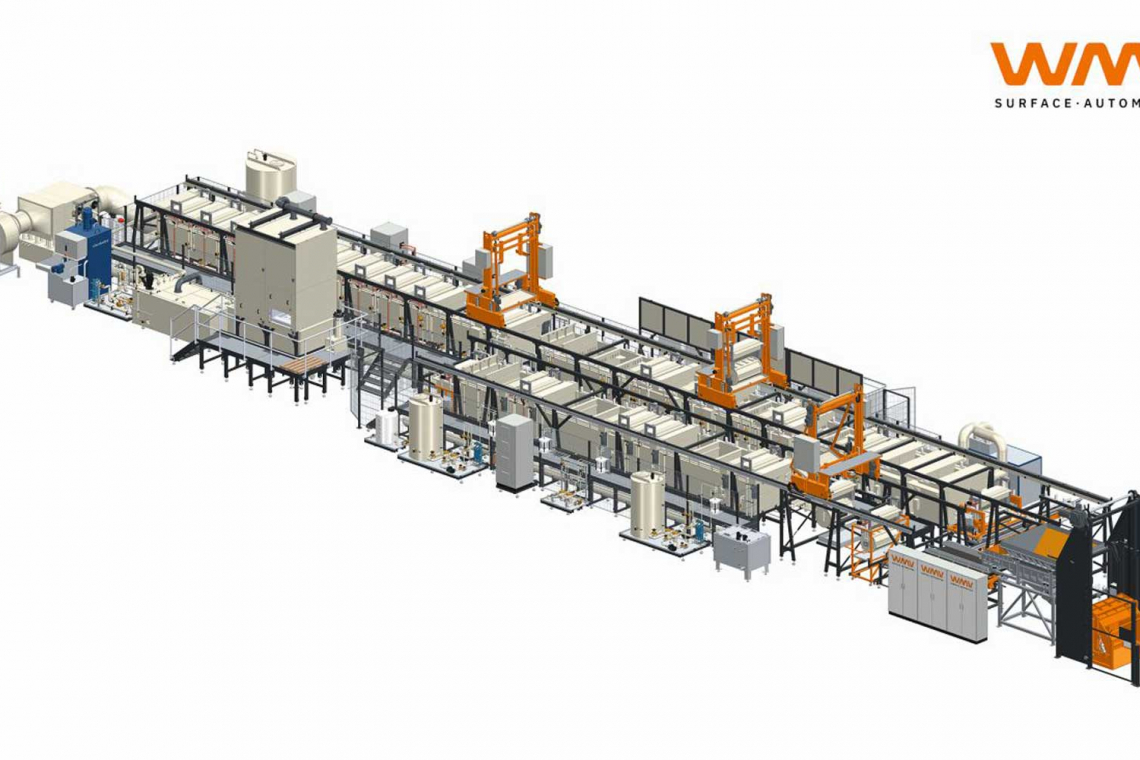

Conventional electroplating systems are often too inflexible and cost-intensive. This is precisely where WMV comes in as a specialist in the design and manufacture of modular systems for industrial surface treatment. With existing solution concepts such as the well thought-out modular principle, which combines flexibility and adaptability with a high level of implementation expertise, WMV realizes electroplating systems in a modular design that enable an innovative, efficient and future-oriented system concept.

Efficiency through preconfigured modules

The modular design with preconfigured modules reduces engineering, production and assembly times. Interface optimization, compact design and high system reliability also reduce follow-up costs - while at the same time allowing individual adaptation to specific requirements. The central control of all relevant interfaces and deadlines by WMV ensures smooth processes, high planning reliability and a significantly lower project risk.

Optimized interfaces and compact design

During development, particular attention was paid to optimizing the interfaces, a compact design and a technically reliable solution. The transfer processes have been significantly improved thanks to the optimized interaction of the responsible components. In particular, loss and damage to the customer's goods to be coated were significantly reduced.

Space costs money: This approach led to a compact design of the electroplating system and its components. Whereas rectifiers and drain tanks are often installed at a distance from the system, in WMV systems they are directly assigned to each process bath and located in the immediate vicinity. In addition, consistent compliance with DIN 17059 and preventive fire protection are a particular focus when designing the system.

WMV - "always a winning combination"

WMV has been driving the efficiency of surface treatment "Made in Germany" worldwide for 55 years. Personal support and 24/7 service round off the WMV portfolio. WMV is TOP 100 Innovator 2025.