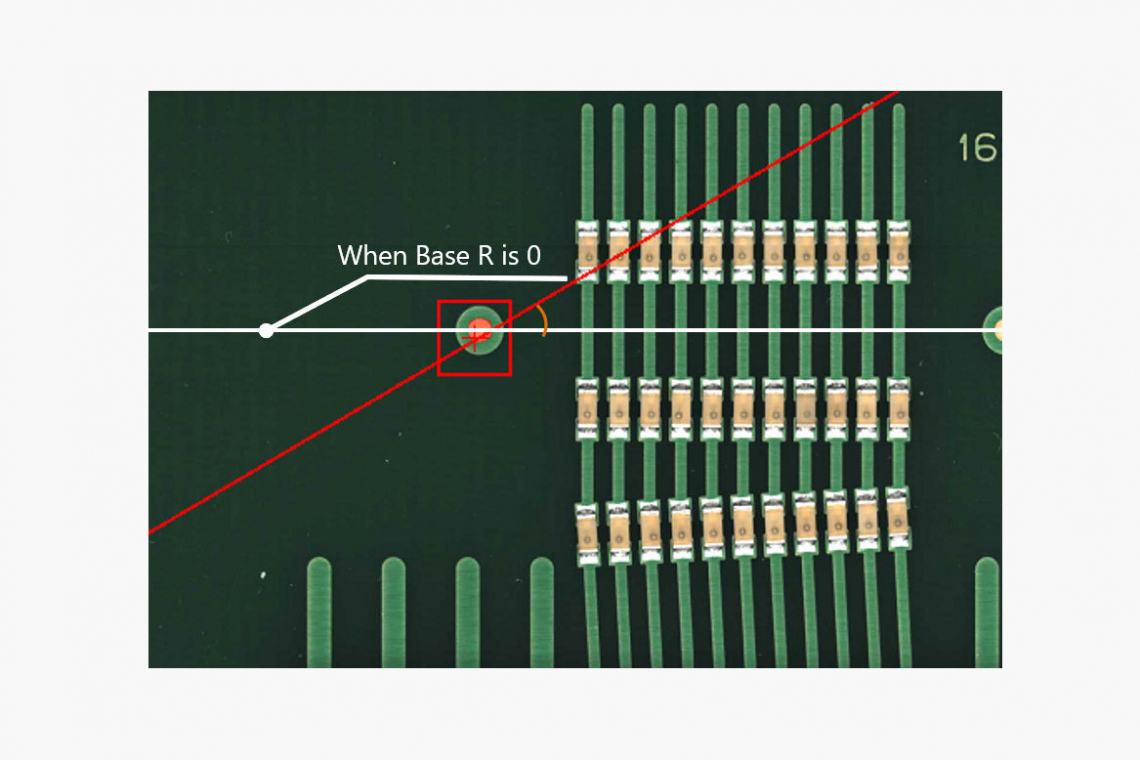

A new alignment check, which checks the correct arrangement of adjacent components very quickly and precisely, is one of numerous new and enhanced features of the YRi-V 3D AOI system. The new function is used, for example, to individually optimize automotive LED systems for optimum light output. The alignment check can also be used to monitor the correct distances between numerous other components, such as Hall sensors for precise motion control.

YRi-V, Image: YamahaTheSMT Section of the Yamaha Robotics Business Unit has implemented further new functions for its AOI system - such as faster handling of assemblies. A new, stop-free transport system electronically brakes and stabilizes each assembly after it enters the machine, thus reducing the required positioning time. The overall time saving noticeably increases overall productivity.

YRi-V, Image: YamahaTheSMT Section of the Yamaha Robotics Business Unit has implemented further new functions for its AOI system - such as faster handling of assemblies. A new, stop-free transport system electronically brakes and stabilizes each assembly after it enters the machine, thus reducing the required positioning time. The overall time saving noticeably increases overall productivity.

The LED coplanarity measurement and the height measurement system based on a blue laser have been further developed. The latter also ensures accurate and repeatable measurement for transparent LED housings - this was only possible to a limited extent with conventional systems. With all these features, Yamaha's AOI system specifically supports lighting manufacturers in the field of LED solutions to achieve higher product reliability with superior optical performance and optimized visual appearance.

The physical basis of the 3D AOI system - as with Yamaha's YRM high-speed placement unit - is a highly rigid frame: This allows the super-sharp image capture with its many possible camera resolutions, an 8-directional 3D projector and its state-of-the-art image processing unit to achieve extremely high throughput while detecting hard-to-detect defects such as chipping and cracks in wafer-level packages. A 25 megapixel camera is available as an option, which significantly expands the image area that can be captured simultaneously.

Offline processing tools and AI-supported automatic library matching accelerate the creation of inspection programs and help to minimize the time required to introduce new products. As part of the Yamaha 1-Stop Smart Solution concept, defect information is shared with other devices in the line to speed up analysis and defect detection.

The newly introduced functions are available immediately in all new machines. They can also be retrofitted to existing systems.