Much has been said and written in recent years about fragile supply chains - also, but not only, in electronics. There are many reasons for this. But hardly anyone will doubt that they are also a consequence of the relocation of production to China. Time for a sober summary.

Around 50 years ago, companies usually had two or more suppliers for their key products. Each of these companies had a certain percentage of the total requirement; they usually knew each other and exchanged products. This system was a kind of 'insurance', because if problems arose with one supplier, the others could step in.

China then opened its borders to foreign producers. As a result, the idea of maximizing profits - that nations should only produce what they were best at and import the rest - took hold. In addition, China pursued a clever industrial policy (production in exchange for know-how with the simultaneous participation of domestic companies), which also helped the country to grow.

The result was a network-like structure with China at its center. In the first two decades of its existence, this structure was built up and expanded, and there was a tailor-made supply chain for every product and its individual parts.

Later, in the early 1990s, several events contributed to the further success of this model: geopolitically, peace prevailed, the collapse of the Eastern Bloc opened up a completely new market, and the Internet allowed for an immediate transfer of data and knowledge. In addition, the limitation to just one supplier ('single sourcing') was introduced to further increase profits, as larger delivery volumes meant that lower prices could be enforced. As consumers could afford more, tourism also increased. Goods of all kinds were transported halfway around the world at short notice in the cargo hold of airplanes.

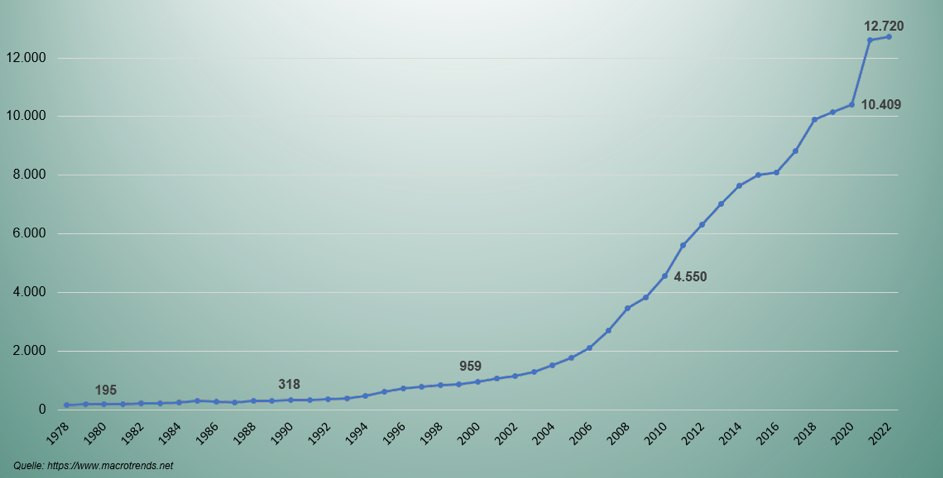

This meant a considerable upswing for China: when the country opened up, the gross national product per capita was less than 200 dollars - forty years later it had multiplied to over 12,000 dollars ...

Fig.1: China's gross national product in $ per capita

Fig.1: China's gross national product in $ per capita

Collapse of the supply chains

With the growing success, however, politicians made demands. Initially with stricter laws based on international standards, the lack of which accounted for part of the cost advantage for years, and in recent years there has been significant interference in business decisions.

Just how fragile the supply chains really are has become clear in the last three years. In logistics, tried and tested routes were suddenly no longer available. The interruption of the sea route through the Suez Canal, the closure of airspace over Russia and Ukraine or the climatic change that makes passage through the Panama Canal more difficult are just a few examples of the critical situation that the global economy can find itself in within a very short space of time. The procurement strategies practiced for decades ('just-in-time' - or even worse: 'just-in-sequence') led to the collapse of supply chains.

With the outbreak of the pandemic in 2020, large parts of production, domestic logistics, international freight flights and sea transportation came to a standstill. In addition, the increasingly harsh tone between the US and China set a process in motion that led to a rethink and a review of relationships.

Only relatively slowly are purchasing departments and boardrooms beginning to change their thinking.

The search for other supplier countries under the premise of "China +1" repeatedly focuses on just a few alternatives: Vietnam, Thailand, India. However, these are only suitable to a limited extent and the Philippines, Indonesia or Malaysia cannot be a substitute either, and even the repeatedly mentioned 're-shoring' or 'near-shoring' is only a limited alternative.

Semiconductors without printed circuit boards?

Politicians are aiming for a higher proportion of self-sufficiency in semiconductor production - but unfortunately the goals they are aiming for are too short-sighted, as the necessary infrastructure is lacking. A semiconductor industry without a PCB industry, a PCB industry without a laminate industry, etc. are doomed to failure.

The new locations in Asia or Europe are dependent on primary materials from China because the procurement policy of earlier years forced the industries that used to exist in many countries to close down. However, consideration should now be given to rebuilding lost branches of production in the coming years.

However, it is important to break away from previous ways of thinking: Mega-factories are not at all necessary for security of supply. This also changes the logistics: smaller means of transportation can, for example, bring semi-finished goods to final production and port and storage facilities can be smaller as a result. This also means that the focus is no longer on single sourcing (although in the past this was a successful way of putting pressure on the suppliers concerned).

The crises of the last few years have shown that supply chains in their current form have reached the end of their resilience and new concepts are needed.