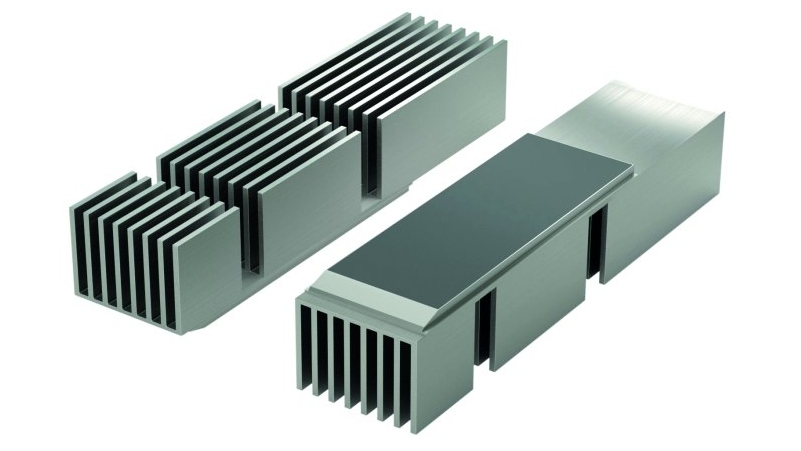

Effective thermal management is becoming increasingly critical in hyperscale and cloudscale data centers, especially during the transition to the 400 GbE standard when larger bandwidths need to be processed. This is where the new Bergquist microTIM mTIM 1000 series from Henkel with innovative microthermal coatings provides a remedy by permanently securing and improving heat dissipation between the pluggable optical modules (POM) and their associated heat sinks.

Once applied to the heat sink, the new materials provide a stable micro-TIM coating that reduces the temperature by up to 5 °C per 16-W POM. With up to 32 POMs per line card, this results in significant savings throughout the server. Prospective user testing has shown that Bergquist microTIM mTIM 1000 Series materials can withstand up to 500 insertions and removals of modules without degradation in performance, exceeding industry test standards.

Unlike conventional TIM pads, which are often damaged or removed when modules are changed, the new microTIMs are mechanically very robust. This contributes to their advantageous behavior in demanding high-performance 400 GbE systems. They are applied to heat sinks made of aluminum or copper in extremely thin layers of 20 µm. The microTIMs are also resistant to corrosion caused by salt spray. They can be used at operating temperatures between -40 and +200° C. Two versions are available: microTIM mTIM 1013 and microTIM nTIM 1029.