Presentations and live demos on the electronics production process chain were held at the Ersa GmbH Technology Forum, which took place in Wertheim at the end of September. Head of Sales Rainer Krauss moderated the event, which was attended by around 120 customers, business partners and interested parties.

After the lockdown in mid-March, the event was one of the first opportunities for experts from the electronics production industry and its environment to come together again and exchange ideas directly. This was seen as an important signal for everyone and a step back to normality. The event was held in compliance with a strict hygiene concept, which began at the reception with registration, including temperature checks, in a separate tent on a road that was closed to traffic specifically for this purpose. Nevertheless, everyone visibly enjoyed the technology forum. Rainer Krauss

Rainer Krauss

"It's the first event in this format for Ersa - and we've done everything we can to fully depict electronics production with printing, assembly and soldering with the involvement of our business partners. We wanted to make the most of this time and engage in direct dialog with you, our customers and partners, face to face," said Rainer Krauss. In addition to the technical presentations and live exhibits, participants were able to take part in factory tours of the new Ersa Plant 2 to see how the soldering systems are produced in state-of-the-art flow cycle production at Industry 4.0 level. One floor up in the Customer Care Center, which is usually reserved for customer acceptance tests, there were live demonstrations of Ersa systems and equipment presentations by business partners in areas such as assembly, AOI and exhaust air filtration.

Lecture series doubled in parallel sessions

The organizer's strategy of doubling the lecture series on both days in two parallel sessions both reduced the number of participants per individual lecture and made it possible for individual participants to select lectures without being spoilt for choice. On the second day, it was possible to catch up on lectures that had been missed on the first day due to overlaps. The first day began with basic lectures on wave soldering, selective soldering and stencil printing. These were followed by presentations on automated piston soldering and automated rework. In between, topics such as digitalization were covered. During the factory tour, production manager Lutz explained how the cycle production of the soldering systems works

During the factory tour, production manager Lutz explained how the cycle production of the soldering systems works

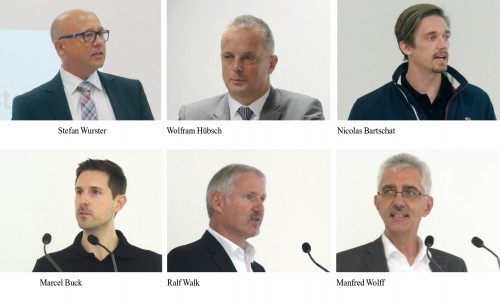

Under the title 'Selective and wave soldering: maximum flexibility for every requirement', Stefan Wurster presented the THT soldering processes. In these processes, energy is essentially transferred by contact between the solder joint and liquid solder. The interaction of the relevant process parameters (solder temperature, wetting time, solder wave height, solder nozzle diameter) and the boundary conditions at a solder joint (solder heat requirement, solder resistance, heat capacity, wettability and layout) were discussed, as was the defined flux application as part of a no-clean process. The aim of the wave or selective soldering process is to achieve 100% solder penetration and at the same time avoid solder bridges - for example between the pins of connector strips. The diverse possibilities of modern, modular wave and selective soldering systems offer the user an effective and flexible solution for reliably soldering a wide variety of applications.

To ensure that minor problems during the individual process steps in production do not become major difficulties, numerous influencing factors must be taken into account - such as the circuit board, components, process, systems used and the environment. In his presentation '100% first pass yield starts in stencil printing with Versaprint 3D-SPI', Wolfram Hübsch explained that it is worth taking a closer look at the printing process in particular, as its error potential in the SMT process is almost two thirds. Possible improvements can be realized in equipment (process times, tolerances), process (squeegee parameters, cleaning, inspection), material (PCB, solder paste, stencil) and environment (ESD, operator). In view of today's extensive range of components, full-surface 3D inspection is now standard - especially when determining the volume of very small pads. Perfect stencil printing should produce precisely shaped, sharp-edged, flat solder deposits with a constant volume. A surface printed with more than 90 % is still considered perfect, a surface printed with more than 70 % is sufficient. If less than half is printed, the result is not acceptable. In addition to tips on avoiding tombstones, solder beads and voids, possible PCB problems were addressed, e.g. uneven pad surfaces, excessive solder resist, bent or stretched PCBs, frayed edges, color and surface changes. With smart, cloud-based printing systems on a modular basis, process-relevant system parameters can be monitored in such a way that zero-defect production is within reach.

In the presentation 'Industry 4.0: Ready for the digital future with Kurtz Ersa Connect', Nicolas Bartschat presented a central gateway solution for the digitalization of electronics production, ranging from entry-level solutions - so-called 'quick wins' - to fully networked production. This end-to-end hardware and software infrastructure includes the following features: intelligent ticket system, machine monitoring, remote service, digital machine database, e-learning and OEE dashboard. When connecting production facilities to a Manufacturing Execution System (MES), industry-proven industry standards are used to ensure the greatest possible security, transparency and future-proofing.

Rainer Krauss and Marcel Buck provided information on the 'Key Solutions for THT electronics production'. These included quality check solutions, pick-and-place handling and soldering system peripherals such as lifting, lowering or turning stations, height compensation modules as well as transport lines and inline and offline workstations. Several best-practice solutions in the field of automation, including robot handling, were also presented.

In the presentation 'Void-free vacuum soldering for future applications: 5G. E-mobility. LED lighting technology. High-current technology' provided information on reflow soldering with a vacuum chamber. By avoiding voiding, the soldering quality can be shifted further towards perfection. This begins even before the soldering process through successive steps such as layout of the PCB and printing of the solder paste as well as assembly. After the soldering process, the quality is assessed by X-ray or AOI. The quality of the PCB and solder paste as well as the components to be assembled are relevant for the soldering result. Homogeneous heat transfer in the reflow soldering system is one of the decisive factors - but other boundary conditions also influence the soldering process, such as the specification of components and PCB, stability of the assembly (structure, design, panel layout) and standards to be complied with. An optimal reflow target profile consists of the preheating, peak and cooling zones - with important process parameters such as temperature profile, volume flow, transport speed for high throughput, cooling, process gas and center support, which prevents the PCB from bending in order to achieve the lowest possible temperature differences (small ΔT) over the entire assembly. The use of a measuring system that records the reflow cycle and measures the temperatures at solder joints and on component housings is recommended here. There was no problem with the minimum distance even for presentations with many participants

There was no problem with the minimum distance even for presentations with many participants

The Ersa Electronic Tools division also presented solutions for hand soldering, rework and inspection in lectures. In the presentation 'Hand soldering & solder fume extraction - safe manual processes and health prevention in the workplace', Ralf Walk explained what is available today. These include the i-CON Vario 4, a practically perfect soldering workstation. This soldering and desoldering station is designed for the connection and simultaneous operation of an i-TOOL AIR S and three other contact heat soldering tools.

Manfred Wolff provided information on 'Automated piston soldering with the SolderSmart - repeatable and reliable'. The Ersa SolderSmart SR 500 works with the powerful i-TOOL, which has been tried and tested thousands of times. Its heating power of 150 W enables fast soldering processes at a stable soldering temperature and the use of different soldering tips (from 0.4 mm up to 5 mm). Other highlights include automatic soldering tip measurement (height), spot and line soldering, flow soldering with pre-soldered soldering tip, electric soldering iron feed, automatic loading of soldering programs with optional hand scanner and complete process monitoring. This makes it possible to realize precise, automatic piston soldering with maximum precision. Exhibition of the complete Ersa product range supplemented with equipment from partner companies

Exhibition of the complete Ersa product range supplemented with equipment from partner companies

In addition, the presentation 'Automated rework - ultimate flexibility from 01005 to big boards' presented systems with which everything from the smallest chip components and PCBs with dimensions of 150 x 150 mm to large components of 60 x 60 mm and PCBs with formats of up to 625 x 1250 mm can be processed reliably and reproducibly. This also enables automatic repair. All participants were positive about the combined format of the technology forum and in-house exhibition, so that a repeat next year - hopefully without corona restrictions - is a done deal.