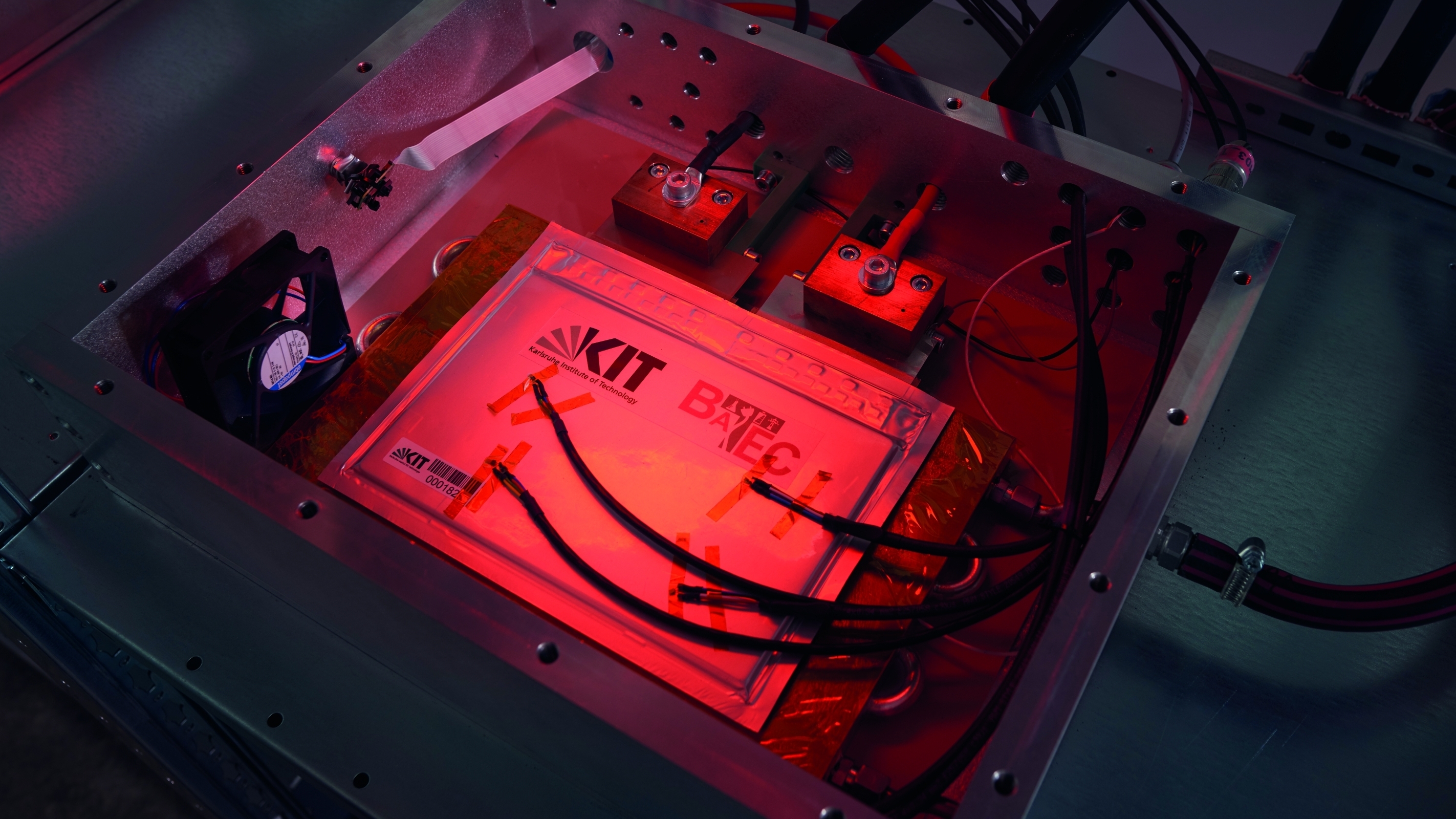

At KIT's Battery Technology Center, a team of researchers is working with partners on more realistic safety standards and tests for lithium-ion batteries. Hardly anyone will ever have found their notebook pierced by a nail. Nevertheless, this is a common procedure in today's safety tests for lithium-ion batteries: "In order to carry out certain tests, the cells must first be massively abused," says Dr. Anna Smith from the Institute for Applied Materials (IAM) at KIT.

In this way, assumed worst-case defects can be triggered inside the cells in order to observe their progression in the battery. In addition to being pierced with nails, cells are also extremely overcharged or overheated. The discrepancy between the test procedure and realistic stress is not without consequences: actual defect progression is not the subject of the investigation, meaning that manufacturing defects in low-quality cells and their risks remain undetected, while cells that are actually safe are put at a disadvantage. "If battery systems are designed for unrealistic worst-case scenarios regardless of their cell quality, this does not make them safer, but rather bulkier, heavier, less sustainable and also more expensive than necessary," says Smith. Her team at the KIT Battery Technology Center is working with the partners AVL Deutschland GmbH, CTC advanced GmbH and TÜV Rheinland LGA Products GmbH as well as the associated partners ads-tec Energy GmbH, Intilion GmbH, Jungheinrich Norderstedt AG & Co. KG, Solarwatt Innovation GmbH, VARTA Storage GmbH and the German Commission for Electrical, Electronic & Information Technologies in DIN and VDE (VDE|DKE) in the research project "Development of a propagation test procedure for lithium-ion cells in battery systems" (ProLIB), funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) with more than €1.2 million, on more realistic safety standards and tests.