The development of sustainable concepts for electronic products and recycling needs to be further expanded for industrial implementation. Researchers from the Dresden University of Applied Sciences (HTW Dresden) will be able to present their findings on alternative biopolymers for bio-based and biodegradable carrier and sensor layers as part of the 'bioESens' project. This was actually supposed to be the subject of an event at HTW Dresden in spring 2020, but it had to be canceled due to coronavirus restrictions.

Electrical and electronic devices or assemblies are usually made from valuable raw materials. Their use and recovery therefore deserves special attention. Today, the search for new and reusable materials, sustainable technologies and recycling processes is important because the printed circuit boards alone, which are found in almost all technical devices, add up to 50 million tons of electronic waste per year - with an annual growth rate of almost 9%. For decades, researchers, developers and users have therefore been working with increasing intensity on sustainable technological solutions.

Metal and plastic recycling

In the Electronics Technology Lab at HTW Carolin Henning and Philipp Zink with their Excellent Poster Award and Best Paper Award from the IEEE for Young Scientists at the ISSE 2020Recoveringprecious metals and other metals from scrap isan ongoing topic. Hydrocyanic acid compounds (cyanides) have been used for this purpose since the end of the 19th century. Selective, high-yield recovery processes without these environmental toxins have been sought, and not just since the EU ban 10 years ago. Recently, researchers from the Korea Advanced Institute of Science and Technology in Daejeon reported in the journal Proceedings of the National Academy of Sciences on a newly developed recycling process based on a highly porous polymer made from so-called porphyrins, which can be used to recover precious metals from electronic waste. The method also works when more than 60 metals are present in a solution.

In the Electronics Technology Lab at HTW Carolin Henning and Philipp Zink with their Excellent Poster Award and Best Paper Award from the IEEE for Young Scientists at the ISSE 2020Recoveringprecious metals and other metals from scrap isan ongoing topic. Hydrocyanic acid compounds (cyanides) have been used for this purpose since the end of the 19th century. Selective, high-yield recovery processes without these environmental toxins have been sought, and not just since the EU ban 10 years ago. Recently, researchers from the Korea Advanced Institute of Science and Technology in Daejeon reported in the journal Proceedings of the National Academy of Sciences on a newly developed recycling process based on a highly porous polymer made from so-called porphyrins, which can be used to recover precious metals from electronic waste. The method also works when more than 60 metals are present in a solution.

Klaus Opwis, who is researching similar metal extraction processes using special textiles at the German Textile Research Center North-West in Krefeld, describes this porphyrin recycling method as a "very promising approach". However, Daniel Goldmann from Clausthal-Zellerfeld Technical University considers the method to be scientifically "not uninteresting", but does not see any approach for large-scale implementation, as the entire e-scrap would have to be dissolved in aqua regia. Katrin Bokelmann from Fraunhofer-IWKS also does not see a standard process here because the process steps with acids and bases are too complex. In addition, these remain as waste at the end. "Melting processes are established for this."

An entire industry has long since developed around the recycling of plastic. The proportion of recycled plastics in industrial products and packaging was around 12% in 2017. However, the industry is currently facing major problems. "Due to the coronavirus crisis, demand from the plastics processing industry continues to fall, resulting in falling prices for both virgin material and recyclates," emphasized Herbert Snell, Vice President of the German Association for Secondary Raw Materials and Waste Disposal. Some recycling plants have already been shut down or are producing at a lower capacity. More cost-effective, more productive processes and sustainable solutions are therefore absolutely necessary.

Bringing sustainability more into the discussion

A joint event organized by the VDE/VDI Saxon Working Group on Electronics Technology (SAET) and the VDE Working Group on Measurement and Automation Technology was held to discuss the topic of 'Sustainability in electronics and sensor technology'. This idea arose from the interdisciplinary collaboration in the 'bioESens' project for young researchers at the HTW Dresden, in which the two chairmen of the working groups, Prof. Reinhard Bauer and Prof. Gunther Naumann, were involved with their colleagues.

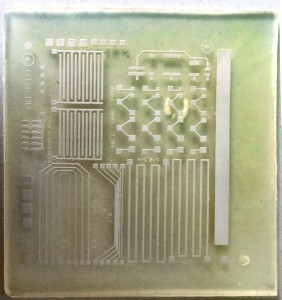

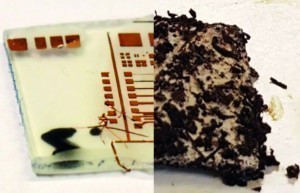

Test structures in polymer thick-film technology on PLA carrier (left) and PLA carrier with copper conductors for testing component assembly (right)

Like so many things in times of Covid-19, this project planned for April and the attempt to postpone it to June failed "in the hope that our lives would have returned to normal by then" (SAET organizer Dr Martin Oppermann from the IAVT at TU Dresden). So this event ultimately became a 'corona victim'!

"Inquiries, not only from the working groups on the topic of sustainability, show that the interest of colleagues in the field is high and very topical," emphasized Prof. Bauer. For this reason, the organizers decided to take up this topic in the 'Report from Dresden' together with the author, who has reported almost regularly on the SAET meetings at the PLUS, and thus make it accessible to interested parties. The following provides information about the bioESens project and an overview of selected key areas based on input from project staff.

The bioESens project

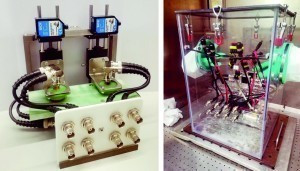

Test benches for material and sensor testingTheuse of biopolymers in electronic components places particularly high demands on compounding and modification in order to achieve the required property profiles. Nevertheless, the bioESens project, which is linked to the Dresden University of Applied Sciences (HTW Dresden) and financed by the European Social Fund (ESF), has found practical solutions for the use of bio-based plastics in the fields of electrical engineering, electronics and sensor technology, covering the entire value chain from biomaterials, their material modification and processing, application in sensor technologies and functions to questions of production technology, application testing, durability and environmental compatibility.

Test benches for material and sensor testingTheuse of biopolymers in electronic components places particularly high demands on compounding and modification in order to achieve the required property profiles. Nevertheless, the bioESens project, which is linked to the Dresden University of Applied Sciences (HTW Dresden) and financed by the European Social Fund (ESF), has found practical solutions for the use of bio-based plastics in the fields of electrical engineering, electronics and sensor technology, covering the entire value chain from biomaterials, their material modification and processing, application in sensor technologies and functions to questions of production technology, application testing, durability and environmental compatibility.

The special feature of the project, explained Prof. Bauer, is the strong interdisciplinary approach between the Faculties of Agriculture/Environment/Chemistry (Prof. Kathrin Harre, Prof. Knut Schmidtke), Electrical Engineering (Prof. Reinhard Bauer) and Mechanical Engineering (Prof. Gunther Göbel, Prof. Gunther Naumann). In an interdisciplinary group of young researchers, graduates from various engineering courses at the HTW were trained in the use, design, development and recycling of products made from bio-based plastics in the areas of project management, social skills, their own teaching activities and interdisciplinary specialist knowledge. The project should also contribute to the transfer of current research results into practice, to the development of new fields of application for bio-based plastics and to the interdisciplinary development of teaching and research in engineering courses.

The publications on the project results, e.g. at the 'International Spring Seminar on Electronics Technology' (ISSE), attracted international attention in 2018 and 2020 and were even awarded the 'Excellent Poster' and the 'Best Paper Award for Young Scientists' by the IEEE.

New biopolymers: suitability for electronic assemblies

With PLA and laser-structured aluminum, similar strengths can be achieved as with conventional plasticsOnefocus of the topic worked on by Anna Schmid and Carolin Henning was the selection and development of new biopolymers as substrate material for wiring carriers and the adaptation to the functional requirements as well as to the technological processes of assembly and interconnection technologies (AVT). Previous sustainable products usually have the disadvantages of insufficient temperature stability and low fire protection. Polylactic acid (PLA) has proven to be suitable for rigid to slightly bendable wiring carriers and polyurethane (PU) for flexible and malleable substrates. They offer the possibility of recycling, use in a materials recycling economy or biodegradation. The base materials were optimized using additives to improve their electrical, mechanical (cellulose acetate), fire protection (zinc pyrophosphate) and processing properties. The base material was optimized on a laboratory scale and, based on this, substrates were produced in small batches by injection moulding for subsequent areas of investigation. Fields of application with limited temperature requirements, limited reliability requirements and duration of use were considered for an entry into electronics, whereby the biocompatibility speaks for applications in environmental and medical technology, for example. In comparative studies, the properties of the optimized substrates come close to FR2 or even yielded slightly more favorable values for some parameters (e.g. dielectric strength Ud = 22 kV/mm, relative permittivity εr = 2.5). Compared to previously known sustainable carriers, an increase in temperature stability was also achieved, which needs to be improved in further development.

With PLA and laser-structured aluminum, similar strengths can be achieved as with conventional plasticsOnefocus of the topic worked on by Anna Schmid and Carolin Henning was the selection and development of new biopolymers as substrate material for wiring carriers and the adaptation to the functional requirements as well as to the technological processes of assembly and interconnection technologies (AVT). Previous sustainable products usually have the disadvantages of insufficient temperature stability and low fire protection. Polylactic acid (PLA) has proven to be suitable for rigid to slightly bendable wiring carriers and polyurethane (PU) for flexible and malleable substrates. They offer the possibility of recycling, use in a materials recycling economy or biodegradation. The base materials were optimized using additives to improve their electrical, mechanical (cellulose acetate), fire protection (zinc pyrophosphate) and processing properties. The base material was optimized on a laboratory scale and, based on this, substrates were produced in small batches by injection moulding for subsequent areas of investigation. Fields of application with limited temperature requirements, limited reliability requirements and duration of use were considered for an entry into electronics, whereby the biocompatibility speaks for applications in environmental and medical technology, for example. In comparative studies, the properties of the optimized substrates come close to FR2 or even yielded slightly more favorable values for some parameters (e.g. dielectric strength Ud = 22 kV/mm, relative permittivity εr = 2.5). Compared to previously known sustainable carriers, an increase in temperature stability was also achieved, which needs to be improved in further development.

Polymer thick-film technology was used to develop cost-effective sensor and wiring carriers. Minimal structure widths of around 200 μm were achieved on both material systems. However, due to temperature stability, the polymer pastes had to be cured below the recommended curing temperatures with a modified temperature-time profile in some cases. An improvement in deformation due to the heat process was achieved by optimizing the curing temperature and adjusting the composition.

Biopolymer wiring carriers with good conductive and mountable structures could be produced using typical PCB technology. Depending on the composition of the PLA carrier, the parameters for laminating the Cu foils were adjusted. A good bond was achieved without an additional adhesive layer due to the meltability of the PLA carrier at elevated temperatures. The lamination quality significantly determines the results of the subsequent structuring. The photolithography, etching and stripping processes are compatible with the new materials under laboratory conditions. Conductor tensile widths in the range of 200 μm were also achieved. Through-hole plating options were also investigated, including black hole technology. This also opened up the use of electroplating for double-sided biopolymer-based PCBs.

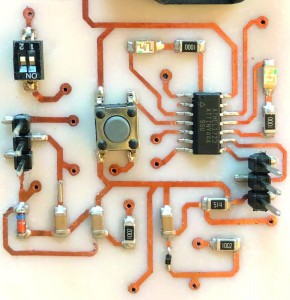

Low-melting solders such as SnBiAg were used to investigate the SMD assembly capability, taking into account the limited temperature stability of the carrier materials. In direct comparison with assemblies on FR4 substrates, the PLA assembly variants produced only slightly poorer results in shear tests on assembled SMDs.

Overall, it can be estimated that functional electronic assemblies based on biopolymers can be realized under laboratory conditions and that biopolymer substrates as wiring carriers in electronic assemblies are generally suitable for sustainable concepts. The introduction of additives into PLA composites offers great innovative potential for adaptation and optimization. Although the resulting higher temperature stability offers better conditions for use and assembly, results comparable to FR4 could not be achieved. The previous investigations under laboratory conditions should also be further expanded and substantiated for practical feasibility in follow-up projects.

Modification of new biopolymers for sensor applications

Daniel Firzlaff and Henry Kettwig were tasked with developing materials for biobased and biodegradable sensor layers as part of the junior researcher project. The polymer film used consists primarily of gelatine. Various additives were used to make the films conductive and more durable. For these tests, biopolymers were selected that cover the widest possible range of applications based on the tested physicochemical properties and contain biobased, biodegradable or naturally occurring additives (plasticizers, crosslinkers, conductive additives). Samples were produced by casting and the composition and its influence on the material properties were tested. Based on this, defined samples (size: 30 x 50 mm) with layer thicknesses of around 0.2 mm with various measurement structures were realized using doctor blade and spin coating processes. Three-dimensional structures were also developed. Electrical contacting was achieved using silver lacquer with pressed-on contacts.

Various tasks, such as the electrical characterization (conductivity and capacitive properties), the characterization of the sensory properties in relation to physical variables such as temperature, humidity or strain as well as the realization of reproducible measurements under constant climatic conditions were processed and measuring stands were set up. The results were illustrated using demonstrators. Depending on the additives used, the biocompatible plastic exhibits a greater sensory effect in relation to humidity than to temperature. If the impedance is considered, the change is approximately 55 kOhm with a change in absolute humidity from 5.5 g/m³ to 15.6 g/m³. The biocompatible plastic represents a good starting point for further sensory developments, for which it must then be specifically designed.

Joining processes with new biopolymers

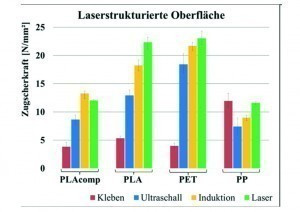

Philipp Zink investigated new joining technologies in order to be able to produce highly resilient PLA-aluminum compounds economically. The aim was to expand the field of application of PLA, which has primarily been used as a packaging plastic to date, for example as a construction material for household appliances, electronic items or decorative elements for the automotive industry. As mixed compounds - plastic-metal - are often used in these areas, PLA and the two reference plastics PET and PP were joined with aluminum using various processes. To increase adhesion, the aluminum surface was subjected to various pre-treatment processes, such as simple cleaning, sandblasting or laser structuring. In addition to the bonding process, the current industry standard, innovative joining processes such as ultrasonic joining and thermal direct joining processes using induction and lasers were used.

The tests showed that PLA and PET can be joined excellently using ultrasonic joining and direct thermal joining (induction or laser heating). With appropriate pre-treatment of the surface, high joint strengths can be achieved that far surpass adhesive joints. Due to the wide range of processes and plastics that were investigated under the same conditions, it is now possible for the first time to directly compare the load-bearing capacities of mixed joints of PLA and other plastics with metal for four industrially important joining processes. The biological origin of PLA is not a disadvantage in these joining technologies. The extremely short process times allow fast handling and therefore very good productivity. By dispensing with additional materials and chemicals, greater sustainability and environmental compatibility are also achieved.

Recycling or composting?

Testing the biodegradability of PLA carriers with Cu conductive structures before and after a composting stageIn order toevaluate the ecotoxicological effects of the gelatine- and polylactic acid-based plastics developed in the project, Richard Zeumer carried out acute exposure studies with aquatic and terrestrial organisms in order to be able to depict the different entry routes of plastics into nature. Both the leached plastics and the additives contained in the plastics were evaluated in acute studies with the large water flea (Daphnia magna) and germination studies with garden cress (Lepidium sativum) in accordance with OECD and ISTA guidelines. Compostability, decomposition and biodegradability of the plastic materials were also determined by composting them for 60 days according to DIN EN ISO guideline 20200 and analyzing their biodegradability in respirometer studies. The environmental compatibility of the resulting composts was then tested in container trials with soybeans (Glycine max). These studies showed a high environmental compatibility of the developed materials and low toxic effects on the tested organisms. Under optimal composting conditions, a high decomposition rate (> 80%) was observed within 60 days. An influence on plant growth by the copper ions released during the composting tests could not be proven. However, further studies are still required for a comprehensive risk assessment of the tested materials in order to ensure the sustainable, environmentally friendly use of bio-based plastics.

Testing the biodegradability of PLA carriers with Cu conductive structures before and after a composting stageIn order toevaluate the ecotoxicological effects of the gelatine- and polylactic acid-based plastics developed in the project, Richard Zeumer carried out acute exposure studies with aquatic and terrestrial organisms in order to be able to depict the different entry routes of plastics into nature. Both the leached plastics and the additives contained in the plastics were evaluated in acute studies with the large water flea (Daphnia magna) and germination studies with garden cress (Lepidium sativum) in accordance with OECD and ISTA guidelines. Compostability, decomposition and biodegradability of the plastic materials were also determined by composting them for 60 days according to DIN EN ISO guideline 20200 and analyzing their biodegradability in respirometer studies. The environmental compatibility of the resulting composts was then tested in container trials with soybeans (Glycine max). These studies showed a high environmental compatibility of the developed materials and low toxic effects on the tested organisms. Under optimal composting conditions, a high decomposition rate (> 80%) was observed within 60 days. An influence on plant growth by the copper ions released during the composting tests could not be proven. However, further studies are still required for a comprehensive risk assessment of the tested materials in order to ensure the sustainable, environmentally friendly use of bio-based plastics.

Findings at the end of the project

The researchers at the HTW were able to gain important insights into the development of sustainable concepts in electronics, which need to be further developed in follow-up projects for industrial implementation in products and production technology. The status achieved is a further important step towards the development of biopolymers in electronics. Under certain conditions of use, products that meet the requirements of sustainability will be possible in the near future for selected applications.

The experience gained from the bioESens project shows that in the field of electronics, a breakthrough in sustainable product concepts requires the greatest possible depth of innovative development work and cooperation, emphasized project manager Prof. Kathrin Harre. The positive results achieved show that the challenges of finding innovative and sustainable solutions require excellent interdisciplinary cooperation between materials development, the various engineering disciplines for processing and application-specific conceptual use through to recycling and disposal. Aspects of the material, product and production concept as well as the application conditions must be considered in a complex and close interaction.

The bioESens project is also a good example of how the 'Sustainable Living' profile line is being brought to life in teaching and research at the HTW Dresden in numerous places, with many interesting results.

Further information:

Saxon Electronics Technology Working Group:

avt.et.tu-dresden.de/saet/arbeitskreis/

BioESens project:

htw-dresden.de/luc/forschung/nachwuchsforschergruppe-bioesens

About the person

About the person

Dr. Rolf Biedorf has been writing for Leuze-Verlag since 1994 and has been reporting on current events in the Saxon microelectronics scene in PLUS for 10 years. After studying chemistry, he worked in the electronics industry and, in particular, at the TU Dresden in research and teaching in the fields of layer and assembly and connection technologies in electronics.