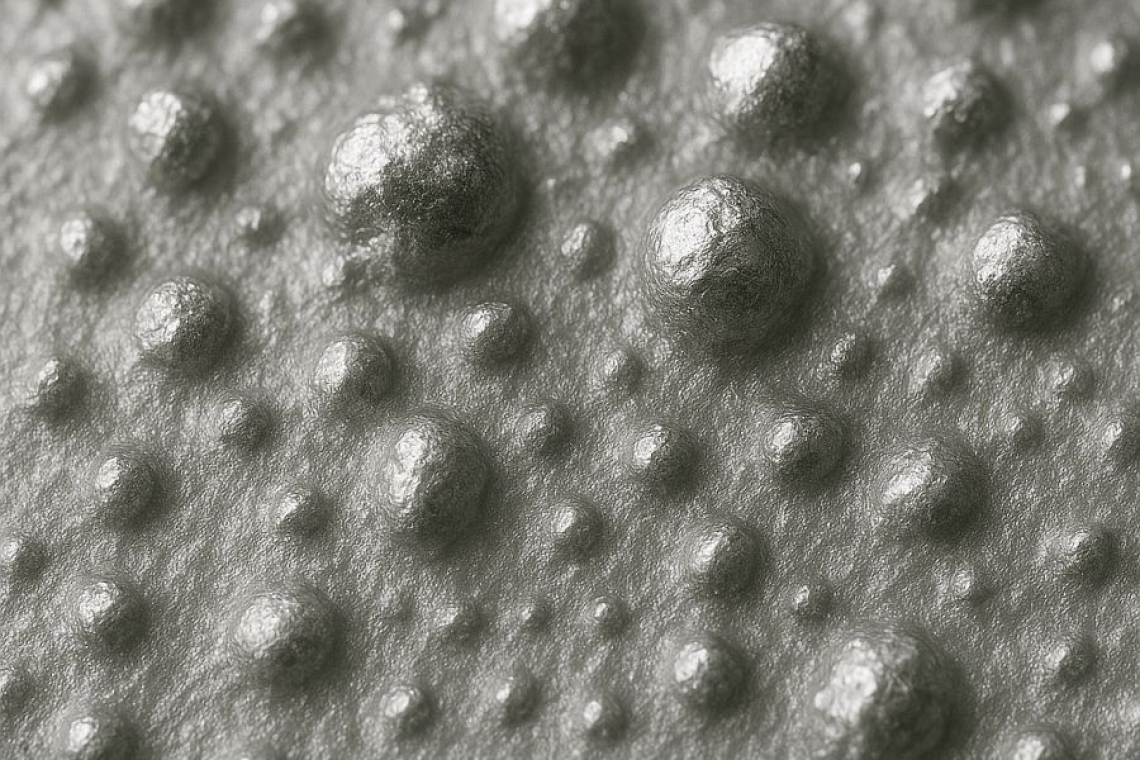

Question: We have been decoratively silver-plating brass parts (CuZn37) for years without any problems. However, for some months now we have been observing pimple-like elevations on the silver layer. The average layer thickness is about 8 µm, but in the affected areas it is 20 µm or more. These are not single crystals as in so-called whiskers, but small, irregular elevations, as if the current density had been increased locally. Even in cross-section - apart from the varying layer thickness - no abnormalities can be seen. Neither inclusions nor impurities can be detected. In addition to visual defects, these unevenly distributed "spots" are causing us increasingly serious problems. Neither our customer, who supplies us with the material, nor the chemical supplier have yet been able to identify a cause - while our complaints are piling up. All the baths and the pre-treatment are in perfect condition and have already been replaced several times.

Answer:

If all possible influences in the electroplating process have been ruled out - and the descriptions suggest this - it is very likely that the cause is not to be found in the electroplating process. In practice, the problems you describe are known to be caused by beta phases in brass with a higher zinc content.

Beta phases refer to a structural component in Cu-Zn alloys that is typically characterized by a body-centered cubic (BCC) crystal structure. This phase differs from the alpha phase, which has a dense face-centered cubic (FCC) structure and usually provides high ductility and good formability. The beta phase is generally harder and more brittle than the alpha phase and is formed under specific alloy compositions and thermal treatment conditions.

In alloys with a zinc content above approx. 35 % (depending on the specific alloy and definition), the formation of beta phases begins to increase. Between the alpha range (lower zinc content) and the purely beta-dominated range, mixed structures can occur in which alpha and beta phases coexist. Many commercially available brass alloys operate in a transitional area in which both alpha and beta phases occur. The exact proportion of beta phase depends on factors such as chemical composition, cooling rates and any subsequent heat treatments. Rapid cooling or unfavourable heat treatments can promote the formation of the beta phase, while controlled thermal processes tend to stabilize the alpha phase. We assume that a change has taken place in the production of semi-finished products, which has led to more beta phases. It is also possible that the supplier was changed for cost reasons and the electroplating company was not informed.

Beta phases are known to have a lower ductility as well as a higher hardness and brittleness. This can lead to problems during mechanical processing. Less generally known are the influences on electrochemical processes. The beta phases often have a different electrochemical potential compared to the alpha phases. There is scientific work that has investigated local potential differences in two-phase brass systems using Scanning Kelvin Probe Microscopy (SKPM). These studies confirm that the potential difference is often around 100 mV [1, 2]. These differences lead to a higher local current density at the beta phase locations during metal deposition. This leads to an increased and uneven deposition of silver in these zones. The result is the observed "spots".

On the surface of the brass, it is not only the pure conductivity that counts, but above all how "ready" the surface is to release or accept electrons. In this context, the difference of around 100 mV between the copper-rich alpha phases and the zinc-rich beta phases is crucial. Even though copper in the bulk exhibits significantly better electrical properties, the specific electronic structure of the beta phase causes the potential to be shifted to such an extent that the silver ions can be reduced more easily. In concrete terms, this means that the activation energy required to overcome the electron exchange process is 100 mV lower in the beta phase zones. This lower barrier means that instead of the usual 8 µm layer, a layer around 2.5 times thicker is actually formed at the beta phases because the reduction process is considerably faster and more intensive here.

At the beta phase, the electron transfer is "rounder", so to speak, which leads to a higher local current density because the energetic footprint of the transition is more favorable than in the copper-rich areas. Despite the fact that copper in solid form is superior as a conductor, this dynamic interplay of potential and reaction kinetics dominates the electrochemical reaction at the surface. As a result, the silver in these zones is deposited at an accelerated rate, which ultimately leads to a significantly thicker deposit. The difference of 100 mV (as an average value) is therefore not simply a number, but represents a significant difference in the energetic profile of the two phases, which ultimately determines that the beta phases act as active nucleation sites and thus cause excessive silver deposition.

As already described, there are various ways to avoid or at least greatly reduce the beta phases. This is most likely the responsibility of the semi-finished product manufacturer. Whether he can get this process under control in the long term is a matter of hope. It would be more sensible to switch to an alloy with <35% zinc in order to avoid the problem permanently.

Further information

[1] Scanning Kelvin Probe Force Microscopy and Magnetic Force Microscopy for Characterization of Duplex Stainless Steels; Journal of The Electrochemical Society; 150 (6) B274-B281 (2003)

[2] Scanning Kelvin probe microscopy of surface electronic structure in GaN grown by hydride vapor phase epitaxy; Journal of applied physics; volume 91, Number 12, 15 June 2002