Question: From time to time we have to deal with complaints about very different materials. Some were polished beforehand, others were simply cast or rolled. The common feature of the parts complained about is that the term "Beilby coating" is mentioned in the course of processing the complaint. Every time we think we have understood the problem, we receive a new complaint that we cannot explain but seems to be the same thing. We would like to get to grips with this problem permanently, but find insufficient information in the literature. It usually boils down to - in our opinion - very different things being described, with "Beilby layer" written in brackets behind them.

We agree with your observations. In conversations with practitioners, you also increasingly hear sentences that start with "It is common knowledge that" and are followed by statements that you have never heard of. With regard to the Beilby shift, it often happens that it is mentioned without any basis, in the hope that nobody will understand it and everyone will just nod in the meeting. We hope that the following explanations will provide some clarity.

George Thomas Beilby

Sir George Thomas Beilby was a British chemist. In 1869, he joined the Oakbank Oil Company to work in the oil shale industry, where he and his colleague William Young werethe first to Described the Beilby layer named after him: British chemist George Thomas Beilby (Photo: Creative Commons/Wikimedia) able to increase the yield of oil, ammonia and other useful materials from the shale through improvements in reprocessing and fractionation.

Described the Beilby layer named after him: British chemist George Thomas Beilby (Photo: Creative Commons/Wikimedia) able to increase the yield of oil, ammonia and other useful materials from the shale through improvements in reprocessing and fractionation.

In 1892, Beilby patented a production method for hydrogen cyanide. This new method used ammonia and coal as feedstocks and was able to meet the increasing demands for sodium cyanide for gold leaching through the MacArthur-Forrest process. He became a director of the profitable Cassel Cyanide Company and then a director of the Castner-Kellner Company at Runcorn, for whom he developed their new factory at Wallsend. He died in 1924 in Hampstead, London.

The Beilby Medal and the Beilby Prize are named in his honor. They are awarded alternately by the Institute of Materials, Minerals and Mining, the Royal Society of Chemistry and the Society of Chemical Industry.

Beilby was the first to deal in detail with the layer on the surface named after him and explained it from the viscous flow of the material during leveling.

The Beilby layer

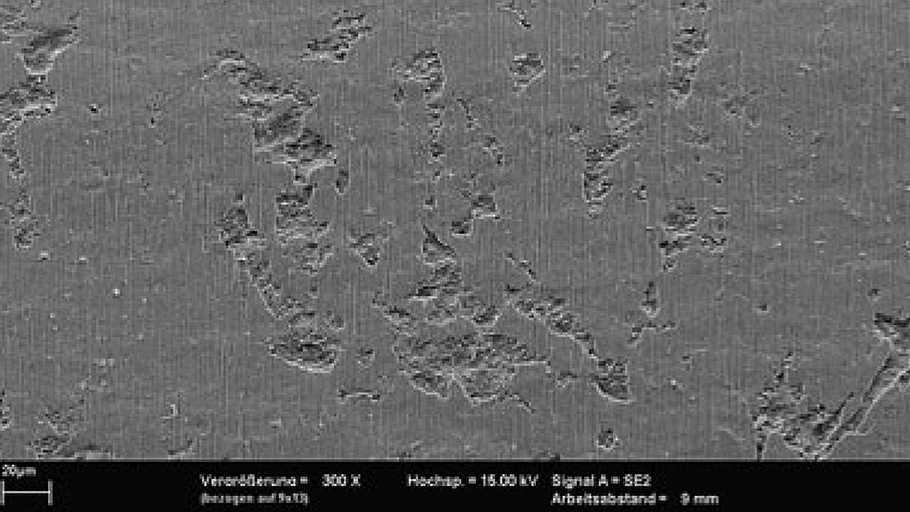

The Beilby layer, also known as the Beilby interference layer, is a layer that appears on the surface of materials that are subjected to sliding or frictional loads. Sliding or frictional stresses" are very wide-ranging and this explains why they can occur on so many differently manufactured metals. These loads occur, for example, during polishing, rolling, extrusion, forging, casting and milling. In electroplating, this is mainly known from mechanically polished parts.

It is a type of tribological layer. It consists of a layer of abraded material particles - it is therefore shattered - which are deposited on the surface and reduce friction and wear. It is amorphous. The layer can also consist of chemical compounds that are formed on the surface as a result of chemical reactions. Today it is assumed that it is not created by viscous flow of the material, but by plastic deformation at higher temperatures.

It can help to prevent corrosion by forming a barrier between the surface of the material and the environment. Under certain conditions, however, the layer contributes to corrosion, such as filiform corrosion. This form of surface attack occurs underneath coatings, preferably under paints and varnishes, and very rarely under an anodic oxidation layer. It mainly involves thread-like, meandering corrosion marks that never cross each other along the surface between the aluminum and the coating. It can also lead to blistering of the coating. Underneath filiform corrosion, corrosion can go deeper due to other types of corrosion. The filaments are normally 100 to 500 nm wide and grow at 400 nm/d. As filiform corrosion spreads along the protective layer under the surface, it ultimately leads to its lifting. The depth of the corrosion attack itself is relatively small (approx. 15 µm).

In practice, the Beilby layer is often combated with lubricants or coatings in order to reduce friction and wear and extend the service life of machines and systems. The Beilby layer can be up to 50 µm thick, but in most cases, especially on surfaces that are to be galvanized, it is significantly thinner (1-10 µm, maximum 20 µm on mechanically polished surfaces). It can be removed by sandblasting or chemical cleaning (see below).

The Beilby layer is created by the high heat input during forming. Only a fraction of it is converted into the natural oxide layer in the air and actually consists of two layers. An upper, thinner, more heavily disturbed layer with a less disturbed layer underneath, which extends into the interior of the material as the degree of disturbance decreases. As it is more energetic, it is electrochemically less noble than the interior of the material.

The layer structure is as follows:

- grease, dirt

- oxide

- Highly disturbed layer

- Less disturbed layer

- Material interior.

Removal of the layer

For subsequent coating, these foreign layers must be more or less completely removed from the workpiece surface. The following types of manufacturing processes are available for this purpose:

- mechanical (chipping, blasting, grinding, polishing)

- thermal (annealing, lasering, (vacuum) evaporation)

- physical (solvent degreasing, sparking, sputtering, ion etching)

- chemical (deburring, pickling, etching, polishing, degreasing)

- electrochemical (deburring, etching, polishing, degreasing).

The task of mechanical surface treatment is to carry out this transition from the initial state to the final state. It is therefore an abrasive process that

- removes surface coatings

- removes and reshapes the top layer of the base material.

It is therefore important to note that the Beilby layer can be removed by mechanical polishing, but it could also be re-formed by heat and reshaping. Incidentally, this is one of the arguments in favor of electrolytic polishing.

At the end of the mechanical polishing process, the surface is

- smooth, possibly shiny or differently structured

- covered with an oxide layer a few nanometers thick, especially in the case of aluminum

- structurally reshaped in a layer a few micrometers thick (Beilby layer) and

- covered with grinding and polishing residues.

A further problem arises from the lack of knowledge about the actual thickness of this layer. For this reason, especially when coating aluminum, the surfaces are blasted beforehand. Here, slurry blasting is the preferred method, as it minimizes material removal and produces a uniform, not too rough surface that is easy to electroplate. 3 µm of pickling is required to remove the coating as completely as possible, followed by decapitation. Excessive pickling should also be avoided, as in this case the substrate is preferentially dissolved and a pickling paste may remain on the surface, which is why preliminary tests must be carried out on new parts to determine the optimum pre-treatment (mechanical and chemical). It is also important to ensure, within the scope of the possibilities of electroplating, that the delivered initial condition always remains the same. Major fluctuations in the surface quality (this therefore applies not only to the Beilby layer) automatically produce a wide range in the quality of the electroplating, which can range from "excellent" to "unusable".

Risk of confusion

In most cases where problems with a possible Beilby coating are discussed, this only happens after electroplating, i.e. when the problem is literally on the table. This leads to the difficulty of proving hypotheses about possible causes. As soon as the surface has been extensively altered chemically, electrochemically or even mechanically as described above, it is almost impossible to reconstruct the original state. Micrographs and further, sometimes time-consuming and costly examinations often only provide evidence that can be misinterpreted. In a more favorable case, traces of elements are found which can have a detrimental effect on electroplating and which demonstrably do not originate from electroplating. In the worst case, further errors occur during the examination, which are then blamed on the electroplating. For example, it is known that a Beilby layer can also occur during the production of a cut, which must be removed before the examination.

In addition, there are influences that can be components of an (original) Beilby layer, but which may also be possible causes of defects in themselves. For example, strong oxide layers that have been insufficiently removed or extreme soiling of the surface that does not exhibit the classic characteristics of a Beilby layer. Overlaps and inclusions that are misinterpreted are also conceivable. The range is very wide and can even be clearly differentiated in individual cases, but to the untrained eye, various causes can look so similar during examinations that they cannot be distinguished.

For this reason, we generally advise increased incoming goods inspection, which should even consist of retaining a small batch size of 5 to 20 pieces per order, preferably from different containers. This is the only sensible way to find out the initial condition when inspecting faulty parts. In the event of complaints about follow-up orders, you can even use this to investigate whether the initial condition has changed over a certain period of time. This can be caused by fluctuations in the material composition, tool wear, new coolants and lubricants during mechanical processing (before electroplating).

If this is not possible, digital photos or other scans, for example under an X-ray, can still provide information about the delivery condition of the surfaces. When taking photographs, ensure that the lighting conditions, distance, resolution and camera settings remain the same so that the images remain comparable over a longer period of time.

We would like to point out one more thing on the subject of examinations. Normally, micrographs are taken to examine the damage under a microscope. It should never be forgotten that the preparation process always influences the surface to be prepared. The aim of such examinations is to expose the "true microstructure". This is defined as follows:

- No deformation

- No introduction of foreign material

- No scratches

- No smearing

- No chipping

- No relief or edge rounding

- No incorrect structure (artifacts)

- No thermal damage.

There is a high risk that the "wrong" microstructure will be shown due to incorrect or inadequate preparation of the samples, which can lead to serious misinterpretations of the cause(s) of the defect. Depending on the extent of the damage, we therefore advise you to entrust two independent institutes with the examination to be on the safe side. Sometimes it's like in medicine: when things get serious, it's better to get a second opinion.