Atmospheric pressure plasma spraying (APS) is an established surface modification process that has a number of advantages. Large workpieces can be provided with a layer up to several millimeters thick in a short time. The range of applications extends from implants for improved ingrowth behavior, with and without antimicrobial effect, in medicine, to technical applications in e.g. turbine blades (corrosion protection and thermal insulation layer)

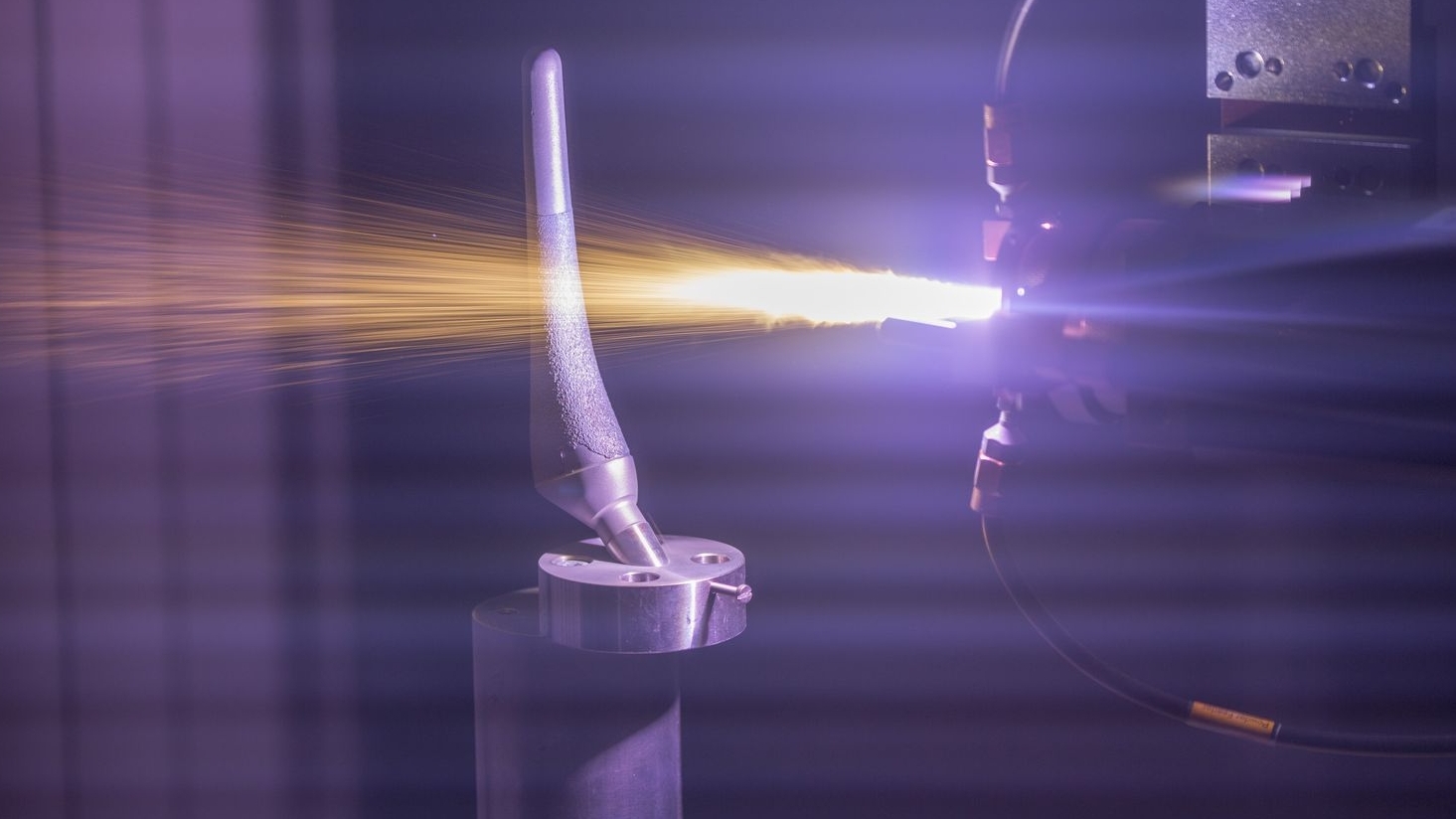

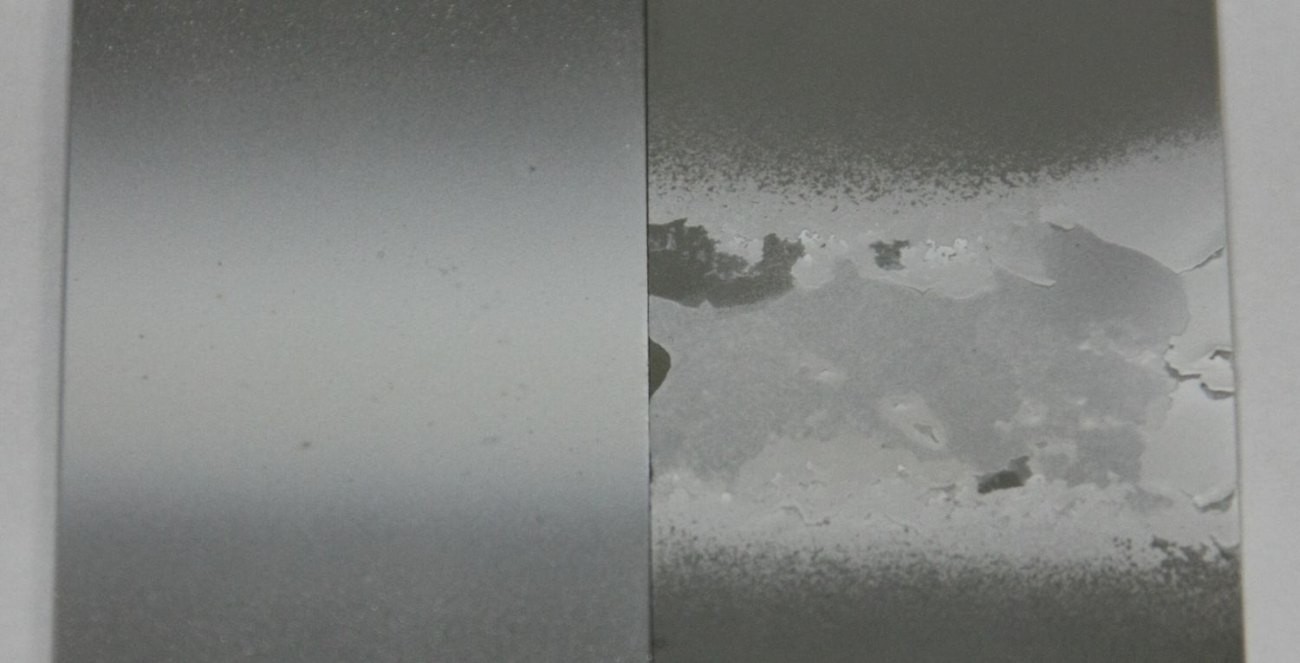

![Abb. 2: Schematische Darstellung des Plasmasprühens [4]](/images/stories/Redaktion_GT/Online-Artikel/thumbnails/thumb_GT-2020-06-Medizin-Abb-2.jpg) Fig. 2: Schematic representation of plasma spraying [4]In plasma spraying (APS), particles with a size between 5 and 200 µm are sprayed into a (thermal) plasma at a temperature of approx. 16,000 °C. These particles are partially or completely melted and move towards the substrate to be coated at speeds of up to 450 m/s, see schematic diagram in Figure 2. With this technique, the substrates to be coated are not melted so that their crystal structure and both their chemical and mechanical properties are not altered. Good pre-treatment of the surface to be coated is very important. This pre-treatment includes (i) cleaning the surface of foreign substances and (ii) roughening by irradiation with abrasive media (e.g. corundum blasting, see Fig. 3). Studies have shown that the plasma-sprayed coating adheres very well to the pre-treated substrate, while coating flaking and delamination occur on the untreated surface [3]. Corundum blasting creates a rough surface that enables purely mechanical adhesion of the applied coating to the substrate. The advantages of plasma spraying are:

Fig. 2: Schematic representation of plasma spraying [4]In plasma spraying (APS), particles with a size between 5 and 200 µm are sprayed into a (thermal) plasma at a temperature of approx. 16,000 °C. These particles are partially or completely melted and move towards the substrate to be coated at speeds of up to 450 m/s, see schematic diagram in Figure 2. With this technique, the substrates to be coated are not melted so that their crystal structure and both their chemical and mechanical properties are not altered. Good pre-treatment of the surface to be coated is very important. This pre-treatment includes (i) cleaning the surface of foreign substances and (ii) roughening by irradiation with abrasive media (e.g. corundum blasting, see Fig. 3). Studies have shown that the plasma-sprayed coating adheres very well to the pre-treated substrate, while coating flaking and delamination occur on the untreated surface [3]. Corundum blasting creates a rough surface that enables purely mechanical adhesion of the applied coating to the substrate. The advantages of plasma spraying are:Atmospheric pressure plasma spraying (APS) is an established method of surface modification, which has a variety of advantages. In this case, large workpieces can be equipped with a layer of up to several millimeters in thickness. The scope of application ranges from implants with enhanced ingrowth, with and without antimicrobial effect, in medicine, to technical applications of e.g. turbine blades (corrosion protection and thermal barrier coatings).

In many areas, surfaces with special properties are required to improve the properties of the base material. These include the aviation sector, where the service life of engine blades is extended by corrosion protection and thermal barrier coatings, for example, or the service life of engine bearings is extended by wear protection coatings [1]. This leads to longer maintenance intervals for aircraft engines and thus a significant reduction in costs. In medical technology, implants are preferably provided with coatings whose material properties are intended to improve the ingrowth of the implants into the bone and prevent the spread of germs, i.e. to prevent infection and thus significantly improve the patient's well-being and avoid the extreme case of implant revision [2]. Figure 1 shows an example of the coating of a hip implant using plasma spraying.

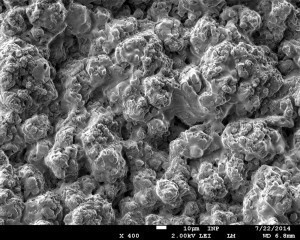

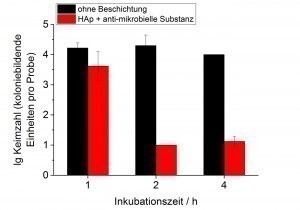

Fig. 4: Comparison of the antimicrobial effect of TiAlV substrates with different incubation times; black: without coating; red: with a hydroxyapatite (HAp) layer with anti-microbial additivePlasmaspraying is highly attractive in the medical field for implant production [3]. The implants can be provided with a titanium or titanium dioxide layer that has a defined roughness and thus significantly improves the ingrowth of the implant into the bone, among other things. Similarly, implants can be coated with a bone-like substance (hydroxyapatite (HAp), tricalcium phosphate (β-TCP)), which can also be equipped with anti-microbial agents (e.g. silver [5], copper or zinc). These are released in the first period after implantation, thus preventing bacterial colonization in the bone. Figure 4 shows the antimicrobial effect of such a multicomponent layer based on results from work at the Leibniz Institute for Plasma Science and Technology e. V. (INP). Almost all pathogens were killed within 2 hours.

Fig. 4: Comparison of the antimicrobial effect of TiAlV substrates with different incubation times; black: without coating; red: with a hydroxyapatite (HAp) layer with anti-microbial additivePlasmaspraying is highly attractive in the medical field for implant production [3]. The implants can be provided with a titanium or titanium dioxide layer that has a defined roughness and thus significantly improves the ingrowth of the implant into the bone, among other things. Similarly, implants can be coated with a bone-like substance (hydroxyapatite (HAp), tricalcium phosphate (β-TCP)), which can also be equipped with anti-microbial agents (e.g. silver [5], copper or zinc). These are released in the first period after implantation, thus preventing bacterial colonization in the bone. Figure 4 shows the antimicrobial effect of such a multicomponent layer based on results from work at the Leibniz Institute for Plasma Science and Technology e. V. (INP). Almost all pathogens were killed within 2 hours.- fast process

- high coating rates

- No melting of the substrate

- coating of polymers possible

- Suitable for a wide range of coating and base materials

- multilayer and multi-material coating systems possible

- coating thicknesses in the range of 50-2000 µm

Fig. 3: Comparison of two stainless steel substrates with an Al2O3 coating; left: corundum-blasted before the coating process, right: not pre-treated

Fig. 3: Comparison of two stainless steel substrates with an Al2O3 coating; left: corundum-blasted before the coating process, right: not pre-treated Fig. 5: Dental implant made of yttrium-stabilized zirconium oxide, coated on the right with TiO2 for better growth behaviourAnotherapplication example is shown in Figure 5, here a dental implant made of yttrium-stabilized zirconium oxide (YSZ) was coated with a TiO2 layer at the INP, which improves growth in the jawbone [6] and at the same time retains the cosmetic aspect of the light-coloured YSZ outside the bone.

Fig. 5: Dental implant made of yttrium-stabilized zirconium oxide, coated on the right with TiO2 for better growth behaviourAnotherapplication example is shown in Figure 5, here a dental implant made of yttrium-stabilized zirconium oxide (YSZ) was coated with a TiO2 layer at the INP, which improves growth in the jawbone [6] and at the same time retains the cosmetic aspect of the light-coloured YSZ outside the bone.>Yttrium-stabilized zirconium oxide is used to protect against thermal stress in aerospace applications, particularly on turbine blades where temperatures of up to 2200 °C occur. Typically, coatings with thicknesses of 50 to 200 µm are deposited [3]. An example of a coated blade can be seen in Figure 7.

The INP also uses a special process to plasma spray thermally sensitive substrate materials that were previously unsuitable for this thermal process and therefore place special demands on the process control. These include polymers such as polylactides (PLA), polyvinyl alcohol (PVA) or polyether ether ketone (PEEK), which are among the modern materials used in medical technology [7].

New processes and coating systems for applications in the high-tech and life science sector are constantly being developed and existing processes improved based on the requirements and novelty of solutions. The plasma spraying process plays a major role here.