Printed flexible electrodes for electroencephalography (EEG) and electromyography (EMG) [1]

Electrodes attached to the skin are the core element for both electroencephalography (EEG) and electromyography (EMG). In addition to good electrical conductivity, the electrodes used must also be skin-compatible and have a low skin-electrode resistance. Today's standard electrodes are made of metal and coated with a conductive gel layer, which creates a large-area electrical contact between the metal surface and the fissured skin surface. During long-term measurements, the gel can dry out and prevent reliable measurements on the patient (Fig. 1).

In the successfully completed BMBF research project "NanoEDGE", an alternative approach was pursued at the Fraunhofer Institute for Biomedical Engineering IBMT - based on the assumption that a low skin-electrode resistance can also be achieved without the use of a gel. To achieve this, the electrode must fit snugly against the fissured skin surface and thus form a large contact surface. For this purpose, the skin electrode is realized as a thin, electrically conductive layer that is printed on a thin and mechanically flexible plastic film.

The production of the skin electrode involves printing an electrically conductive ink on soft film material, followed by cutting and laminating an insulating layer suitable for sticking to the skin. In particular, the thickness of the individual layers and the overall thickness determine the coupling of the electrodes with the skin and therefore the achievable signal-to-noise ratio. The electrodes, which are only a few micrometres thick, in combination with low-cost, miniaturized electronics, serve as building blocks for a new generation of wearable sensors.

First, the printability of various carbon, graphene and silver inks was evaluated using an inkjet printer on an 80 µm thin polyurethane (PU) film. The abrasion resistance, electrical conductivity and skin compatibility of the printed structures were also examined. In order to improve printability, the composition of a commercial graphite ink was subsequently changed. The inks evaluated comprised a total of four silver inks and five graphene or carbon inks. While, as expected, the silver inks proved to be damaging to cells, the graphene or carbon-based inks, including the modified graphene ink, were suitable for subsequent use as skin electrodes. However, the level of electrical conductivity of the electrodes and conductors produced with graphene or carbon inks proved to be insufficient. The approach of creating biocompatible electrodes with sufficiently high electrical conductivity by printing a biocompatible carbon layer on a highly conductive silver underlayer was ultimately successful. Cytotoxicity tests showed that the biocompatible carbon in this multilayer sufficiently covers the cell-damaging silver.

The printing processes developed in the course of the project were finally transferred to an industrial printer at the project partner Notion Systems GmbH (Schwetzingen, Germany), which allows high-throughput printing. The electrode structures were printed on an industrial scale using an n.jet printer from Notion Systems with industrial print heads. The project partners at Tel Aviv University, Israel, demonstrated the suitability of the printed electrodes for both EMG and EEG signal conduction. Application-specific electrode geometries were used in each case. For this purpose, SensoMedical Labs Ltd. in Nazareth, Israel, developed miniaturized sensor electronics for the construction of complete monitoring systems.

A specially developed measuring method and device for characterizing the stiffness of printed electrodes helped to examine the mechanical deformability of structures printed with different inks. By comparing the deformability determined using this method with the signal-to-noise ratio of the derived EEG signals, it was possible to show for the first time that the suitability of skin electrodes for recording EEG signals correlates with the mechanical deformability of the electrodes. This result supports the hypothesis underlying the research project that the best possible adaptation of the electrodes to the contour of the skin is a decisive factor for the low-noise recording of EEG signals.

In the project, the Fraunhofer Institute for Biomedical Engineering IBMT was responsible for the mechanical and biological characterization of the various inks, the design of the process chain and the development of the printing processes. As a result of the project, an ink based on graphene and carbon black is now available for inkjet printing, which has the expected electrical conductivity and good adhesion to PU films. Furthermore, the evaluation results of various commercial silver and carbon inks with regard to printability, biocompatibility and electrical conductivity are available.

A process chain for printing mechanically flexible electrode structures on a thin PU film substrate with the subsequent application of an insulating layer has been developed and is ready for transfer to industrial applications. By combining a highly conductive silver ink with a biocompatible ink based on carbon nanoparticles, biocompatible electrode structures can be produced that are suitable for the low-noise recording of EMG and EEG signals [2].

Photoelectric nerve stimulation [3]

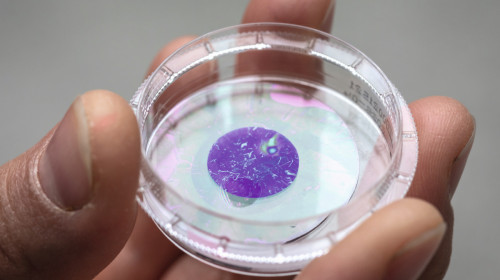

A completely new type of implant: wafer-thin and light-sensitive pigment foils, for example to stimulate nerve cells. An international research team has successfully developed and tested a concept in which nerves are stimulated with light pulses. The technology enables completely new types of implants that can be used to stimulate nerve cells and was developed in a joint effort by researchers from Graz University of Technology, the Medical University of Graz, the University of Zagreb and CEITEC (Central European Institute of Technology). It is based on color pigments from the food industry, such as those used in organic solar cells. The pigments are vapor-deposited to form a layer just a few nanometres thick, where they convert light into electrical charge - just like in organic solar cells. Nerve cells cultivated on the film react to this charge and in turn fire electrical impulses to stimulate other nerve cells (Fig. 2).

Fig. 2 : A completely new type of implant: ultra-thin and light-sensitive pigment foils, for example for stimulating nerve cells

Fig. 2 : A completely new type of implant: ultra-thin and light-sensitive pigment foils, for example for stimulating nerve cells

The researchers have now been able to demonstrate this process for the first time in cell biology experiments. Cultured nerve cells that grew directly on the film were stimulated by several short flashes of light with a wavelength of 660 nanometers (red light), each lasting a few milliseconds, and reacted as hoped: they generated so-called action potentials, which are essential for communication between nerve cells. The researchers have published the results of their electrophysiological measurements and computer simulations in the journal "Advanced Materials Technologies" [4].

In contrast to current electrostimulation using metal electrodes, the pigment films developed represent a completely new way of stimulating nerve cells. The foils are so thin that they can be easily implanted. During treatment, the nerve cells are then irradiated with red light, which can penetrate deep into the body without causing any damage. Short-term treatments should be able to lead to long-term therapeutic effects.

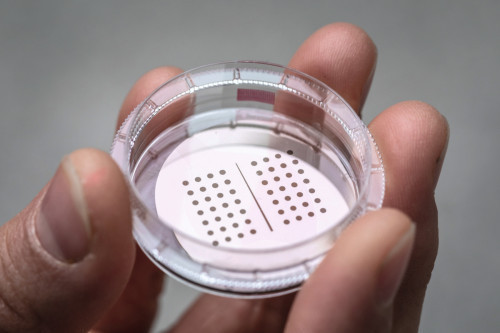

Fig. 3 : The film can be produced in different pigment sizes. Tests are currently underway to determine which structure is best suited for clinical applications (Photo: Lunghammer - TU Graz)

Fig. 3 : The film can be produced in different pigment sizes. Tests are currently underway to determine which structure is best suited for clinical applications (Photo: Lunghammer - TU Graz)

In future, there would no longer be any need for complex cabling of a nerve implant, which in turn would reduce the risk of infection after invasive procedures, as there would no longer be any need for tubes or cables to lead out of the body. Thanks to their organic nature, the pigment films are extremely well tolerated by both human and animal cells (Fig. 3).

The researchers see potential applications in severe brain injuries. Here, the stimulation of nerve cells can accelerate the healing process and prevent complications by preventing the death of nerve cells. The researchers also see potential for other neurological injuries or in pain therapy. The technology could also be used to create new types of retinal implants.

Glucose as an energy source for medical implants and sensorsMini fuel cell generates electricity using the body's own sugar [5]

Dextrose, also known as glucose, is the most important source of energy for our bodies. Scientists at the Technical University of Munich (TUM) and the Massachusetts Institute of Technology (MIT) now want to use the sugar in the body as an energy source for medical implants. They have developed a glucose fuel cell that converts the sugar into electricity.

Medical implants such as sensors for measuring vital functions, electrodes for deep brain stimulation in Parkinson's disease or pacemakers require reliable power sources that are as small as possible. However, batteries cannot be reduced in size at will, as they require a certain volume to store energy.

A research team led by Jennifer Rupp, Professor of Chemistry of Solid State Electrolytes at TUM and Dr. Philipp Simons from MIT has now developed a glucose fuel cell that is only 400 nanometers thick - a hundredth of the diameter of a human hair. Instead of using a battery that takes up 90% of the volume of an implant, the device developed could be applied in the form of thin films on a silicon chip or, in future, even on the surface of the implants.

The glucose fuel cell consists of two electrodes - the cathode and the anode - and an electrolyte layer. The glucose from the body is converted into gluconic acid at the anode, releasing protons in the process. The electrolyte conducts the protons through the fuel cell to the cathode, where they combine with the air to form water molecules. The electrons flow into an external circuit where they can be used to power an electronic device.

The idea of using glucose fuel cells as a power source is not new. Previous devices used plastics as the electrolyte layer. As plastic materials are not compatible with standard production processes in the semiconductor industry, they are difficult to apply to silicon chips, which are the state of the art in medical implants. Hard materials are required for this. Another disadvantage is that the polymers that make up the plastic are partially damaged when the implants are sterilized.

The researchers therefore used ceramic electrolytes for their fuel cell. The chosen ceramic can be easily miniaturized and integrated on a silicon chip and is biocompatible. The material can also withstand high temperatures.

The team produced 150 of the glucose fuel cells on a chip, each about 400 nanometers thin and about 300 micrometers wide. The researchers mounted the cells on silicon wafers, demonstrating that the devices can be combined with a common semiconductor material. They then allowed a glucose solution to flow over each wafer.

The scientists found that many of the fuel cells produced a peak voltage of around 80 millivolts. This voltage is sufficient to power sensors and many other electronic devices for implants. Considering the tiny size of each cell, this is the highest power density of any glucose fuel cell design to date.

It is the first time that proton conduction in electroceramic materials can be used to convert glucose into electricity [6].

Sources and references

[1] Source: Fraunhofer Institute for Biomedical Engineering IBMT

[2] Final report: Nano-based portable electronics for the diagnosis of mental disorders and functional restoration, production technologies and devices (NanoEDGE), published,

http://publica.fraunhofer.de/documents/N-644064.html

[3] Source: TU Graz

[4] Schmidt, T.; Jakešová, M.; Đerek, V.; Kornmueller, K.; Tiapko, O.; Bischof, H. et al.: Light Stimulation of Neurons on Organic Photocapacitors Induces Action Potentials with Millisecond Precision, Adv. Mater. Technol. 2022, 2101159

https://doi.org/10.1002/admt.202101159

[5] Source: TU Munich

[6] Simons, P.; Schenk, S.A.; Gysel, M.A.; Olbrich, L.F.; Rupp, J.L.M.: A Ceramic-Electrolyte Glucose Fuel Cell for Implantable Electronics, Advanced Materials, April 2022, https://doi.org/10.1002/adma.202109075