Developments in microfluidics make new diagnostic systems and microfluidic chips adapted to new requirements possible and could lead to a reduction in the cost of previously expensive processes. Surface technology processes also play an important role in the production of lab-on-chip systems on an industrial scale. The article supplements the state of research on microfluidics presented in issue 2/2022.

University of Freiburg: Precise metabolic monitoring of 3D tumor tissue outside the body [1]

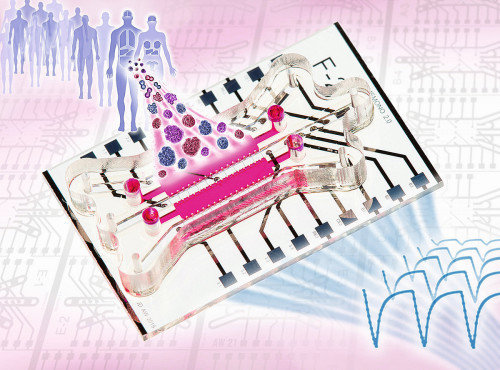

Fig. 1: Organ-on-chip systems with the patient's own cells could enable personalized therapiesAresearch team led by Dr. Andreas Weltin, Dr. Jochen Kieninger and Johannes Dornhof from the Institute of Microsystems Engineering (IMTEK) at the University of Freiburg has developed a system that makes it possible to investigate the development of tumour cells outside the human body in a three-dimensional network. The team has realized an organ-on-chip system that can measure and control the culture conditions and metabolic rates of the cells at any time using microsensors. Until now, this was only insufficiently possible in 3D cell cultures. The system was developed in collaboration with the Molecular Gynecology Department at the Clinic for Gynecology and Obstetrics at RWTH Aachen University Hospital. In the future, the patient's own cells in organ-on-chip systems could enable personalized cancer therapy (see Fig. 1) [2].

Fig. 1: Organ-on-chip systems with the patient's own cells could enable personalized therapiesAresearch team led by Dr. Andreas Weltin, Dr. Jochen Kieninger and Johannes Dornhof from the Institute of Microsystems Engineering (IMTEK) at the University of Freiburg has developed a system that makes it possible to investigate the development of tumour cells outside the human body in a three-dimensional network. The team has realized an organ-on-chip system that can measure and control the culture conditions and metabolic rates of the cells at any time using microsensors. Until now, this was only insufficiently possible in 3D cell cultures. The system was developed in collaboration with the Molecular Gynecology Department at the Clinic for Gynecology and Obstetrics at RWTH Aachen University Hospital. In the future, the patient's own cells in organ-on-chip systems could enable personalized cancer therapy (see Fig. 1) [2].

In organ-on-chip systems, three-dimensional tissue models are connected to each other by an artificial circuit so that they act like miniature organs on a microchip. In this way, physiological processes - such as the growth of a tumor - can be simulated and observed outside the human body. The research group developed a chip design with integrated microsensors and microfluidics that can measure the metabolites of the cells directly on site. In their system, the team grew breast cancer mini-tumors from individual stem cells and used the electrochemical sensors to monitor the cells' oxygen and glucose consumption and lactate production over the course of a week.

The platform enables the dynamic 3D culture of tumor organoids, whereas previously static 2D cultures were often used, which can only depict the complex microenvironment of a tumor to a limited extent. In addition, the chip system can also be used to test the effect of drugs on cell metabolism - for example, the cellular effect of chemotherapeutics in cancer research could be recorded quantitatively and in real time.

The use of the patient's own stem cells makes it possible to replicate an original tumor outside the body. This could offer new opportunities for personalized therapy, for example with regard to possible resistance to certain chemotherapeutic agents, which is crucial in aggressive triple-negative breast cancer. In future, it should be possible to test the effectiveness and side effects of a patient's medication in organ-on-a-chip systems.

The results underline the potential of integrating microsensor technology into organ-on-a-chip systems in cancer research and drug development.

Fraunhofer IWS: From prototype to series production quickly with lab-on-chip systems [3]

It is used millions of times around the world every day: as a portable laboratory in miniature format, the corona antigen rapid test is currently clearly demonstrating the potential of lab-on-chip systems. The analysis it enables within a few minutes is of immense importance, especially during the pandemic. More and more of these miniature medical systems are being used in diagnostics. However, the development and production of more complex test systems is associated with high costs. In the SIMPLE-IVD research project, researchers at the Fraunhofer Institute for Material and Beam Technology IWS are working with several partners to develop new manufacturing processes and methods for the cost-efficient production of rapid test cartridges.

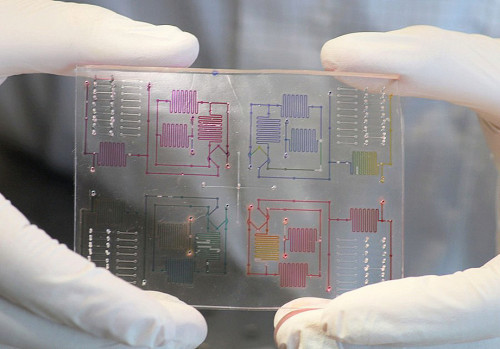

Fig. 2: In the SIMPLE-IVD project, design rules are being developed and tested that make it possible to produce in-vitro diagnostic cartridges that are functionally equivalent using different manufacturing processesLab-on-chip systemsare only a few centimetres in size, but combine various functionalities in this small space that in the past were only possible in well-equipped laboratories. They will play a particularly important role in personalized medicine in the future. The smallest amounts of liquids from patient samples can be analyzed completely automatically. The ease of handling will also enable laboratory diagnostics close to the patient in the future. Various lab-on-chip systems have been developed around the world in recent years. However, only a small number of these have come onto the market. The hurdle is scaling up the tests developed on a laboratory scale for mass production. The Fraunhofer IWS developed a solution for these problems during industrialization.

Fig. 2: In the SIMPLE-IVD project, design rules are being developed and tested that make it possible to produce in-vitro diagnostic cartridges that are functionally equivalent using different manufacturing processesLab-on-chip systemsare only a few centimetres in size, but combine various functionalities in this small space that in the past were only possible in well-equipped laboratories. They will play a particularly important role in personalized medicine in the future. The smallest amounts of liquids from patient samples can be analyzed completely automatically. The ease of handling will also enable laboratory diagnostics close to the patient in the future. Various lab-on-chip systems have been developed around the world in recent years. However, only a small number of these have come onto the market. The hurdle is scaling up the tests developed on a laboratory scale for mass production. The Fraunhofer IWS developed a solution for these problems during industrialization.

The "Scalable Microfabrication of Polymeric In-Vitro Diagnostic Systems" (SIMPLE-IVD) project focuses on the in-vitro diagnostic cartridges (IVD cartridges) for the rapid tests (Fig. 2). Prototype production processes are currently still lacking for the transition from small series to large quantities. Additive manufacturing processes or multilayer lamination, i.e. the construction in layers of polymer films that would be implemented in injection molding or roll-to-roll processes for series production, are used for production in the laboratory. Until now, manufacturers had to start from scratch to scale up to a different process.

With the help of the special, newly developed design rules developed at the IWS, manufacturers can incorporate requirements for a wide range of manufacturing processes for prototype development as well as for small and large series into their design as early as the planning phase for the IVD cartridges. The design rules have already been developed for several classic manufacturing technologies. In addition to injection molding and vacuum casting, these also include multilayer lamination, deep drawing and several additive processes. Specific application-related solutions can also be developed as quickly as possible. A reverse translation from large to small series would also be practically possible. The design sets are not only of interest to manufacturers of IVD cartridges. There are currently numerous biotechnology start-ups that need precisely such possibilities.

The major advantage of this innovative method is that prototypes and small batches can be turned into industrial solutions faster than before. Lab-on-chip systems therefore reach market maturity faster and are available to users more quickly. Development times are almost halved with the new method.

The results are to be translated into a universal data set by the end of the project in 2022. The process should make it possible to produce functionally equivalent IVD cartridges. The aim is to achieve the same high quality of end products using different methods, which will enable identical results in the application. Customized IVD tests enable individual and permanent screening of diseases in the healthcare sector. It could also be used for diagnostic home care applications in nursing homes or care facilities.

TU Dresden: Microfluidics for fast and inexpensive PCR tests [4]

Fig. 3: Novel microfluidics-based PCR rapid test systems are being developed at TU DresdenTodevelop a PCR rapid test for Covid-19 and other pathogens this year - that is the goal of a new junior research group at TU Dresden. The novel test is intended to combine the advantages of rapid antigen tests, i.e. fast test results, with the advantages of PCR tests, i.e. high accuracy. Such significantly more efficient tests will enable the comprehensive diagnosis of future waves and pandemics.

Fig. 3: Novel microfluidics-based PCR rapid test systems are being developed at TU DresdenTodevelop a PCR rapid test for Covid-19 and other pathogens this year - that is the goal of a new junior research group at TU Dresden. The novel test is intended to combine the advantages of rapid antigen tests, i.e. fast test results, with the advantages of PCR tests, i.e. high accuracy. Such significantly more efficient tests will enable the comprehensive diagnosis of future waves and pandemics.

The comprehensive diagnosis of SARS-CoV-2 infections has proven to be one of the most important and effective measures in the current pandemic. It can be used to quickly identify sources of infection, clarify chains of infection, accurately predict the regional and nationwide incidence of infection and sustainably reduce the dynamics of infection. By far the most tests are carried out using rapid antigen tests. These can be carried out at any time due to their simple test procedure and sufficient availability, but have only a low reliability (40-50% of tests are false negative or positive).

PCR tests allow a much more reliable diagnosis, higher sensitivity and enable the detection of new mutations. However, they cannot be carried out in as many cases as the simple rapid antigen tests. They require significantly more testing, specialist personnel and expensive automated analyzers and special chemicals, which limit the testing options and are currently leading to critical test bottlenecks.

The PCR rapid tests (Fig. 3) are intended to represent a new generation of tests that combine the simplicity and good availability of rapid tests with the high sensitivity and reliability typical of PCR. The new tests to be developed should provide very reliable results in less than 20 minutes and require 90 % less detection chemicals per test compared to PCR tests.

The project "Next Generation: Rapid tests for the resource-saving and highly sensitive diagnosis of viral and bacterial infections with multiplex LAMP-CoV Guard" is funded by the European Social Fund as part of the EU's response to the Covid-19 pandemic. The Institute of Semiconductor and Microsystems Technology, the Institute of Clinical Chemistry and Laboratory Medicine and the Institute of Medical Microbiology and Virology at TU Dresden are involved in the research.

Fraunhofer IWS project coordinator Florian Schmieder checks the prototype of a complex in-vitro diagnostics cartridge for blood separation. In the SIMPLE-IVD project, the Fraunhofer IWS is developing new methods for the cost-efficient production of such cartridges (Photo: Fraunhofer IWS)

Literature

[1] Source: Albert-Ludwigs-University Freiburg

[2] Dornhof, J.; Kieninger, J.; Muralidharan, H.; Maurer, J.; Urban, G.A.; Weltin, A.: Microfluidic organ-on-chip system for multi-analyte monitoring of metabolites in 3D cell cultures, In: Lab on a Chip, 22 (2) 2022, DOI: 10.1039/d1lc00689e (free download without registration)

[3] Source: Fraunhofer IWS Dresden

[4] Source: TU Dresden