3.1 Glass syringe barrels

The wetting properties were initially investigated on flat substrates, as the water contact angle is much easier to measure here than in the syringe barrels. Values of around 105° were measured on the flat substrates. In order to verify this on the coated syringe barrels, comparative measurements were carried out on uncoated and coated syringe barrels. These are shown in the following figure.

Fig. 2: Comparison of the water contact angles in uncoated glass syringe barrels (top) and coated syringe barrels (bottom)

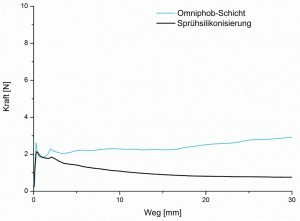

The investigation of the sliding friction effect in comparison to the commercial products shows that comparable values can be achieved using the coating method presented here [3]. Despite the slightly higher sliding friction values, the authors believe that the advantages over conventional baked-on siliconization outweigh the disadvantages: the very low thickness of the applied layer and its uniformity, the reduced interaction with the filling medium and the avoidance of droplet formation in the filling medium as well as the simpler process control without additional energy-intensive temperature treatment (Fig. 3).

3.2 Plastics

The tests carried out on wettability on plastic substrates clearly showed that a glass-like adhesion promoter layer is necessary on all plastic materials examined. Moreover, some plastics are not suitable for coating even with an adhesion promoter layer, e.g. POM and PA6, which is due to the low acid stability of the plastics.

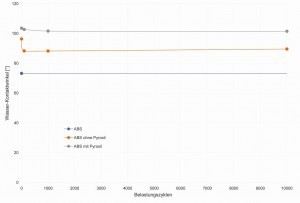

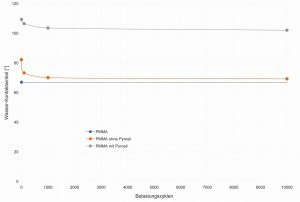

The following diagrams show that the adhesion promoter layer has a different influence on the abrasion resistance of the omniphobic coating depending on the plastic.

A drop of water on an untreated ABS surface formed contact angles of approx. 73° in the tests. In the case of an omniphobic ABS surface with a corresponding adhesion promoter layer, the water contact angle is approx. 100°; without this adhesion promoter layer, it is somewhat lower, but still stable regardless of the number of abrasion cycles and approx. 20° higher than with uncoated plastic. No influence of mechanical stress on the wettability can be seen here (Fig. 4).

In the case of PMMA, the influence of the adhesion promoter layer on the resistance of the omniphobic coating is also clearly visible: without the adhesion promoter layer, the water contact angle of the plastic equipped with the omniphobic layer falls back to the value of the uncoated substrate as the number of abrasion cycles increases. In contrast, the samples initially equipped with the adhesion promoter layer show a water contact angle of over 100° even after 10,000 abrasion cycles. This behavior can also be found with PET-A substrates (Fig. 5).

3.3 Titanium substrates

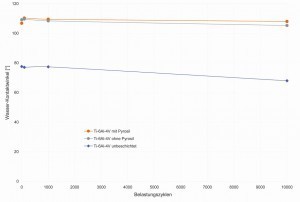

The coating solution binds well to the Ti-6Al-4V alloy even without an adhesion promoter layer. The contact angle of water compared to the uncoated sheet material is around 78°; both with and without the Pyrosil adhesion promoter layer, the value with the Omniphob coating is over 100°.

The abrasion resistance of the coating was tested both with and without the adhesion promoter layer. It was found that a water contact angle of over 100° was still measurable for all samples even after 10,000 abrasion cycles. The measured values with and without adhesion promoter are almost identical (Fig. 6).

3.4 Finish on functionalized surfaces

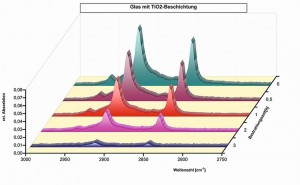

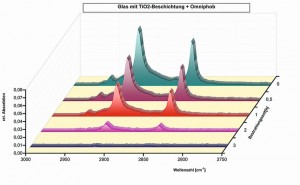

It is also interesting to use the Omniphob coating on functionalized materials, as a kind of finish. These materials retain their properties - this has been demonstrated, for example, on photocatalytically active surfaces that were subsequently equipped with the coating. Photocatalytically active titanium oxide coatings on float glass were subsequently functionalized with the omniphobic coating. Both samples were then coated with stearic acid - this serves as a model substance for organic impurities. Several irradiation cycles were then carried out, each in conjunction with an IR spectroscopic examination of the CH bands characteristic of stearic acid on the surface of the samples. Since it is not a closed layer, an exchange between the ambient medium and the original substrate is possible. The decrease in peak intensity is associated with the degradation of the model substance due to irradiation. Practically no difference can be detected.

Fig. 7: Comparison of stearic acid degradation on photocatalytically active glass, left without and right with omniphobic finish

Conclusion and outlook

It has been shown that hydrophobic coatings can be applied to various substrates using a simple wet-chemical method, without complex treatment and without an additional annealing step. Depending on the substrate material, however, it is necessary to apply a glass-like adhesion promoter layer to which the coating solution can bond. The transparent coating ensures contact angles with water of over 100° and is also highly resistant to abrasion with the appropriate adhesion promoter layer. This can counteract the tendency of the substrate materials to become soiled, and even with regular cleaning, as is the case in the medical field, there is no reduction in functionality.

a reduction in functionality.

The coating can also be used as a sliding layer, significantly improving the sliding friction behavior of the coated substrates. It can also be used as a finish on functional surfaces without impairing their function. There are many conceivable applications for the coating.

Acknowledgements

Parts of the work presented here were financially supported by the BMWi under FKZ MR150028.

Literature

[1] B. Zeiß: Optimal use of silicone oil in prefillable syringes, TechnoPharm, 6(2016)5, 264-275

[2] B. Reuter; C. Petersen: The siliconization of syringes, TechnoPharm, 4(2012)2, 238-244

[3] T. Tölke; J. Rudolf; A. Pfuch; B. Grünler: Syringe siliconization - Alternatives to the bake-on process, PharmInd, 81(2019)3, 404-409

[4] S. Arens; M. Hansis: Implants in trauma surgery: Osteosynthesis with titanium, Ärzteblatt, 95(1998)24, A1516-A1518

[5] B.D. Ratner (Editor): Biomaterials Science: An Introduction to Materials in Medicine, Elsevier, (2013)117

[6] D. Gianom; M. Conti; T.K. Hotz: Osteosynthesis material removal - sense or nonsense? SwissMedical Forum, 2016

[7] G. Klein: Safe and with an attractive design - plastics in medical technology, Kunststoffe, (2013)2, 54-57

[8] A. Heft; T. Hädrich; T. Struppert; A. Pfuch; M. Homuth; B. Grünler: Deposition of thin functional layers at atmospheric pressure, Jahrbuch Oberflächentechnik, Leuze Verlag (2008)64, 137-149

[9] L.M. Wang; T.J. McCarthy: Covalently Attached Liquids: Instant Omniphobic Surfaces with Unprecedented Repellency, Angew. Chem., (2016)128, 252-256