In minimally invasive heart surgery, a drug-coated balloon catheter is increasingly replacing risky stent treatment. A new device is intended to automate manual coating. A team from the Fraunhofer IPK and partners developed the prototype of the coating machine.

Anyone suffering from shortness of breath and severe chest pain may be affected by coronary heart disease (CHD). Around six million people in Germany currently suffer from it. If it is not treated, it can have serious consequences, including a heart attack. CHD is one of the most common causes of death in adults. The disease is caused by calcium deposits on the inner walls of the arteries. The deposits block the arteries and the heart is no longer supplied with sufficient oxygen.

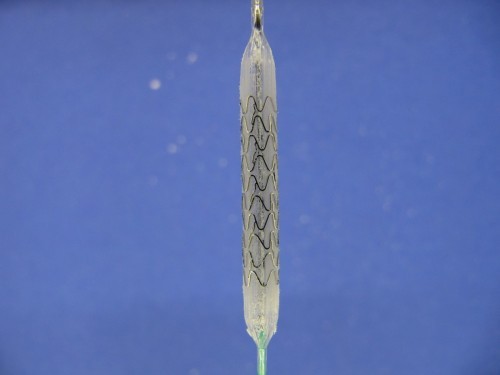

Doctors therefore expand the constriction so that the blood can flow freely again. To do this, they insert a balloon catheter with a plastic support - a so-called stent - into the narrowed artery. When the balloon catheter is inflated, the stent expands, widening the stenosis. The problem: the tissue around the stent can grow back into the blood vessel within a few months. The result is a renewed narrowing - restenosis. Due to this risk, doctors are increasingly opting for an alternative procedure that does not leave a foreign body in the damaged arteries: Balloon catheters coated with immunosuppressants and cytostatics create a mechanical dilation of the vessel when they are expanded. The active substances transferred in the process can prevent restenosis over a long period of time, i.e. increased cell growth of the tissue due to the mechanical stress and thus the re-closure of the vessel. The active ingredient is transported directly to and into the artery walls via the balloon surface.

The coating of the catheter with medication, especially with particularly advanced drugs, is currently often carried out manually by specialists. This process is time-consuming and error-prone. The process is specialized, and specialists with the relevant expertise are rare.

A team at the Fraunhofer Institute for Production Systems and Design Technology IPK is therefore researching how the laborious process of coating balloon catheters can be automated. In the joint project "Heliko - Automated and reliable coating of balloon catheters", funded by the German Federal Ministry of Education and Research (BMBF), they are developing the prototype of a coating machine. They are working closely with InnoRa GmbH, a spin-off from the Charité hospital in Berlin, and Organical CAD/CAM GmbH. InnoRa has developed and patented numerous coating processes, while Organical is developing the machine system for the automated coating system so that the balloon catheters can be mass-produced. The aim of the project is to reduce the reject rate, significantly increase balloon sales and guarantee process reliability.

A stent on a balloon catheter coated with medicationNot aneasy task, as the microscopic crystals of the medication should ideally point outwards in the same direction. This is the only way for the active ingredient to penetrate the cell walls particularly quickly and effectively. Parameters such as the layer thickness and the nature of the coating surface play a decisive role. The balloon catheters must transport the drug into the arterial wall immediately; this process must not take longer than one minute so that the oxygen supply to the heart is not interrupted for too long. The surface must therefore not be too smooth; a directed crystal conformation ensures better transfer of the active ingredient. At the same time, the desired structure of the crystals prolongs the duration of action of the drug in the arterial wall. The balloon catheter is deflated and removed again after the drug has been delivered.

A stent on a balloon catheter coated with medicationNot aneasy task, as the microscopic crystals of the medication should ideally point outwards in the same direction. This is the only way for the active ingredient to penetrate the cell walls particularly quickly and effectively. Parameters such as the layer thickness and the nature of the coating surface play a decisive role. The balloon catheters must transport the drug into the arterial wall immediately; this process must not take longer than one minute so that the oxygen supply to the heart is not interrupted for too long. The surface must therefore not be too smooth; a directed crystal conformation ensures better transfer of the active ingredient. At the same time, the desired structure of the crystals prolongs the duration of action of the drug in the arterial wall. The balloon catheter is deflated and removed again after the drug has been delivered.

Numerous factors such as kinematics, pressure strength, coating speed, coating duration and rotation speed influence the crystal structure and therefore the design of the automatic coating machine. The balloon of the catheter is a fragile, extremely thin membrane that has to be coated in an expanded state. This is very difficult. The slightest error can lead to a tear in the 20 to 80 μm thin membrane. The construction of the coating unit by Fraunhofer IPK is correspondingly challenging.

In order to achieve crystallization of the solution on the balloon membrane in the desired conformation, it is necessary to precisely control the crystallization conditions during the coating process. Two motors rotate the wire on which the balloon is stretched so that it can be coated evenly from all sides. The coating head is positioned in relation to the balloon membrane. The coating process then takes place sequentially, with the balloon rotating and the coating head moving along the path at the same time. An integrated high-resolution optical surface measuring device performs quality control by constantly measuring the coating thickness. The coating process usually takes three to five minutes. The throughput can be massively increased compared to the manual process. The advantages are process reliability and quality control by the measuring device. The researchers are currently optimizing the prototype. In a further step, the effectiveness of the balloons will be tested in in-vivo studies. The coating machine should be ready for the market in early 2023.