Scientists at Dresden University of Technology have developed an integral manufacturing technology for the production of complex patient-specific stent grafts using Jacquard coil shuttle weaving technology.

The challenge of patient-specific implants

Demographic change in society is leading to a high proportion of people with cardiovascular diseases requiring treatment. Cardiovascular diseases are already the most common cause of death in Germany with over 340,000 cases [1]. The incidence of aortic aneurysms, i.e. bulges in the aorta, leads to case numbers of around 364,000 in the OECD countries alone [2]. To treat such aneurysms, so-called stent grafts are used, which restore the natural course of the aorta and thus replace the sagged vessel (graft function) and ensure blood flow by keeping it open with the help of stent structures (stent function). Vascular prostheses are currently manufactured on the basis of machine-woven tubes. All the necessary tube modifications are then integrated using cutting and sewing techniques. This assembly includes fenestrations, diameter changes along the length, branches of different lengths and length adjustments. Finally, the individual stents are sewn on completely manually and in an extremely time-consuming process.

As part of a project funded by the German Federation of Industrial Research Associations (AiF), the Institute of Textile Machinery and High Performance Materials Technology at the Technical University of Dresden (ITM) has therefore developed a CAD-supported, integral manufacturing technology for the production of complex patient-specific stent grafts using Jacquard coil shuttle weaving technology [3]. The flexible technology offers solutions for the integration of shape memory materials, such as differently preformed nitinol wires, without the need for additional manual assembly. Based on the developments, tubular mesh with integrated preformed nitinol stent rings with variable diameters, fenestrations and branches that vary over the length of the implant can be realized.

Flexible generation of customized stent grafts

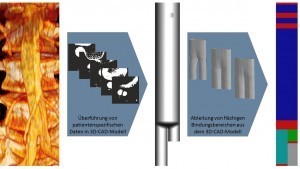

Fig. 1: Conversion of computer tomography data sets into a 3D CAD model to derive flat binding areas for weaving technology implementationACAE-supported process chain (see Fig. 1) was developedforindividual customization, which enables the transfer of patient data into parameterizable 3D CAD models and then into binding cartridges for weaving machines.

Fig. 1: Conversion of computer tomography data sets into a 3D CAD model to derive flat binding areas for weaving technology implementationACAE-supported process chain (see Fig. 1) was developedforindividual customization, which enables the transfer of patient data into parameterizable 3D CAD models and then into binding cartridges for weaving machines.

In the first step, the data sets from computed tomography, which are available in the standardized DICOM format (Digital Imaging and Communications in Medicine), are analyzed and processed. With the help of script-based image-processing software evaluation tools developed at the ITM, manufacturing parameters such as diameters and lengths as well as positions of openings or branches are determined from this patient data. This data is automatically built up into a 3D CAD model that allows the individual parameters to be adjusted, for example the patient-specific geometry of the implant. Software-supported algorithms are then used to transfer the 3D geometry into a 2D image with color coding (Fig. 1, right). This two-dimensional bonding representation shows the areas for fenestrations (e.g. for outgoing blood vessels in red), for branches (e.g. the bifurcation of the aorta, also in red), for the leg arteries (turquoise or green) or for the insertion of the nitinol stent rings (blue) separately. The implementation of the automated process chain in the interested companies can be carried out with the support of the ITM for industrial transfer, particularly in SMEs.

Structural training for integral production

Fig. 2: Schematic representation of the binding areas with layer change (tubular fabric: light blue; circumferential pockets: dark blue; nitinol rings: yellow), sectional view of the corresponding fabric bindings and CAD model with integrated nitinol ringFor theintegration of preformed nitinol rings into the fabric, the stent graft structures were designed as tubular fabric with integrated circumferential pockets. The weave of the tube consists of two interwoven tubes. In the areas where the nitinol wire is integrated, the inner tube is woven further on the outside by changing layers. This creates a firmly connected pocket with the main tube, which requires no further finishing and is completely closed [4].

Fig. 2: Schematic representation of the binding areas with layer change (tubular fabric: light blue; circumferential pockets: dark blue; nitinol rings: yellow), sectional view of the corresponding fabric bindings and CAD model with integrated nitinol ringFor theintegration of preformed nitinol rings into the fabric, the stent graft structures were designed as tubular fabric with integrated circumferential pockets. The weave of the tube consists of two interwoven tubes. In the areas where the nitinol wire is integrated, the inner tube is woven further on the outside by changing layers. This creates a firmly connected pocket with the main tube, which requires no further finishing and is completely closed [4].

Figure 2 shows the associated weave areas and yarn layers as well as a CAD representation of the structure resulting from these weaves.

In software for weaving weave development, e.g. DesignScope, the different weaves are then assigned to the respective areas of the 2D color image (see Fig. 1) and the control file for the weaving machine is created from this.

Stent grafts using Jacquard coil shuttle tape weaving technology

In order to form integrally manufactured stent grafts with the aid of bobbin shuttle tape weaving technology, specific adjustments had to be made to the weaving machine in terms of shed geometry and shuttle plate depending on the process and material. The shed geometry was significantly reduced to ensure low-damage processing of the very fine polyester yarns. The machine was also equipped with a bobbin protector specially designed for processing fine yarns. For the production of complex stent grafts, the bobbin shuttle tape weaving machine with Jacquard device was extended to include a height-adjustable V reed, which is used for the production of tubular structures with variable diameters. In the course of integrating the reed and the modified warp densities, further design adjustments were made to the Jacquard machine, such as the adaptation of the choir board, which serves to guide the harness cords above the fabric, or the spring base for fixing the retraction springs below the fabric.

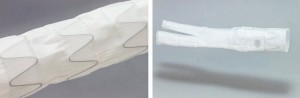

Fig. 3: Stent graft with circumferential Nitinol stent structures (left) and stent graft structure with Nitinol stent, bifurcation (splitting of the aorta into the leg arteries), fenestration (renal branches) and different diameters over the length, manufactured in integral construction (right) As a result of the technical and technological-constructive developments, complex stent graft tubular meshes with variable diameters, fenestrations and branches that vary over the length of the implant can be realized with a high degree of reproducibility. Thanks to the pocket design, the preformed Nitinol stent rings can be inserted in the open compartment position without difficulty, thus enabling the integral production of patient-specific implants. Figure 3 shows stent grafts of varying complexity, which were manufactured for the first time in integral construction on weaving machines based on the technological developments.

Fig. 3: Stent graft with circumferential Nitinol stent structures (left) and stent graft structure with Nitinol stent, bifurcation (splitting of the aorta into the leg arteries), fenestration (renal branches) and different diameters over the length, manufactured in integral construction (right) As a result of the technical and technological-constructive developments, complex stent graft tubular meshes with variable diameters, fenestrations and branches that vary over the length of the implant can be realized with a high degree of reproducibility. Thanks to the pocket design, the preformed Nitinol stent rings can be inserted in the open compartment position without difficulty, thus enabling the integral production of patient-specific implants. Figure 3 shows stent grafts of varying complexity, which were manufactured for the first time in integral construction on weaving machines based on the technological developments.

The textile-physical and structural-mechanical analyses of the integrally manufactured structures show that homogeneous and uniform fabric structures can be realized in all different sub-areas. Furthermore, the stent grafts can be compacted in such a way that they can be inserted into insertion catheters with an inner diameter of 6 mm (18 Charrière) and deployed again without structural distortion. This ensures minimally invasive implantation of the stent graft developed at the ITM.

Specific parameters are required for the approval of stent grafts. These include, for example, determining the force required to separate the stent graft components (graft tissue and Nitinol stent rings) and determining the radial forces, i.e. the force required to keep the tubular implant open during blood flow. The results show that the newly developed integrally manufactured textile constructs partially exceed the characteristic values of comparative structures, which were handmade based on commercially available prosthesis systems. Overall, the analyses carried out together with medical technology companies from the project committee showed that the demonstrators developed in this project meet the required approval-specific requirements very well [5].

Summary and acknowledgements

As part of the IGF-funded research project, the ITM has succeeded in developing a CAE-supported process chain for transferring patient data into complex woven tubular implant structures. Based on the structure and weave developments as well as the technological-constructive developments in the field of Jacquard coil shuttle tape weaving technology, complex stent grafts can be manufactured in an integral design. The achievement of the values required for the approval of stent graft implants and the high complexity of the integrally manufactured structures with different diameters over the length, fenestrations and with a Y-branch show the great medical and technical potential. The solutions developed with the project results with regard to the derivation of control files for the weaving machine from 3D CAD data sets and integral weaving production with high reproducibility not only enable SMEs in the textile industry to flexibly develop medically relevant, highly complex implant and prosthesis structures, but also innovative products, e.g. for compression and muscle support in the sports and leisure sector or the integration of sensory and actuator components in composites.

The IGF project 18774 BR of the research association Forschungskuratorium Textil e. V. was funded via the AiF within the framework of the program for the promotion of joint industrial research and development (IGF) by the Federal Ministry for Economic Affairs and Energy on the basis of a resolution of the German Bundestag.

We would like to thank the above-mentioned institutions for providing the financial resources and the companies of the Project Advisory Committee (PA) for their technical support, as well as all other partners who supported us in our research work on this topic. The final report and further information are available from the Institute of Textile Machinery and High Performance Materials Technology (ITM) at TU Dresden.

Literature

[1] Federal Statistical Office: Statistical Yearbook 2019 - Chapter 4 Health, 2019

[2] Sampson, U.K.A.; Norman, P.E.; Fowkes, F.; Gerald, R.; Aboyans, V.; Song, Yanna; Harrell Jr; Frank E.; Forouzanfar, Mohammad H.; Naghavi, Mohsen; Denen-berg, Julie O.; McDermott, Mary M.; Criqui, Michael H.; Mensah, George A.; Ezzati, Majid; Murray, Christopher: Estimation of Global and Regional Incidence and Prevalence of Abdominal Aortic Aneurysms 1990 to 2010. in: Global Heart 9 (2020), No. 1, p. 159

[3] Schegner, P.; Sennewald, C.; Nuß, D.; Hoffmann, G.; Hübner, M.; Gereke, T.; Brünler, R.; Aibibu, D.; Cherif, C.: Process Chain Development for 3D Net Shape Woven Fabrics. In: Autex World Conference, Ghent, June 11-15 (2019)

[4] Brünler, R.; Schegner, P.; Aibibu, D.; Hoffmann, G.; Cherif, Ch.: Development of a novel weaving technology for the integral production of complex individual stent grafts. In: 30th Annual Conference of the European Society for Biomaterials - ESB 2019, Dresden, September 09-13 (2019)

[5] Brünler, R.; Schegner, P.; Nuss, D.; Wöltje, M.; Hoffmann, G.; Aibibu, D.; Cherif, Ch.: Development of CAD-supported weaving technologies for the production of tailor-made im-plants. In: Aachen-Dresden-Denkendorf International Textile Conference, Dresden, November 28-29, 2019