The neologism 'climate hysteria' has just been voted 'bad word of the year 2019' on the grounds that "in the opinion of the jury, the word defames climate protection efforts and the climate protection movement and discredits important debates on climate protection".

The neologism 'climate hysteria' has just been voted 'bad word of the year 2019' on the grounds that "in the opinion of the jury, the word defames climate protection efforts and the climate protection movement and discredits important debates on climate protection".

One example of a national requirement in the area of climate protection is the Technical Instructions on Air Quality Control (TA Luft). This contains, among other things, calculation regulations for key air pollutants. In the USA, there are regulations from authorities such as the California Air Resources Board (CARB) and the South Coast Air Quality Management District (SCAQMD) that are intended to help improve air purity. As part of its Blue Sky strategy, China has presented a three-year plan to reduce VOC emissions by 10 % by 2020. Various key industries are affected by these regulations, including the chemical industry, the automotive industry and the electrical industry.

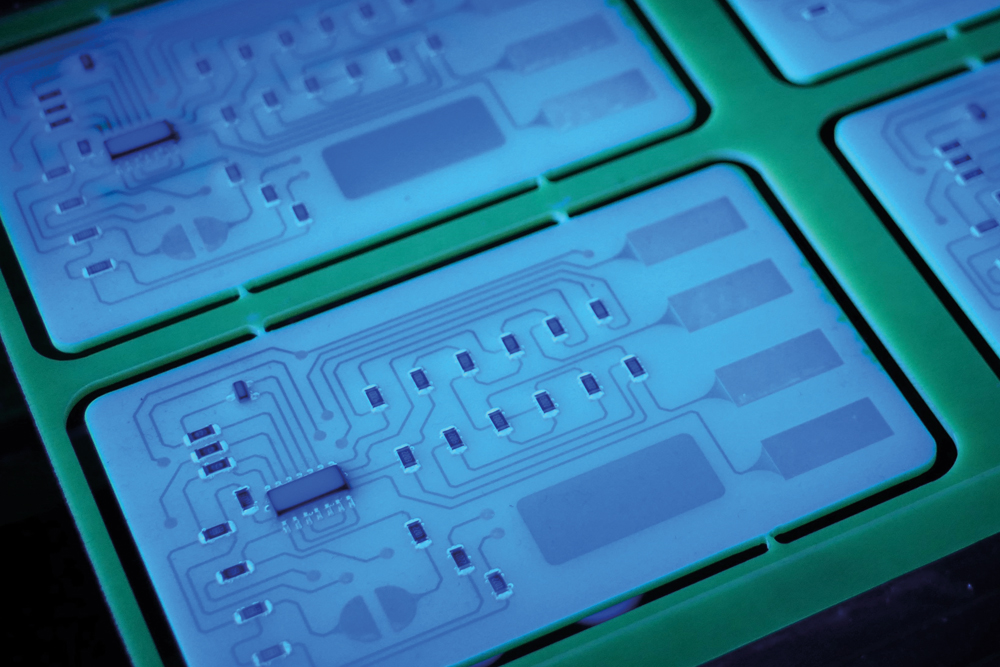

For protective coatings in the electrical industry, a reduction in VOC emissions is possible through various measures in the processing of such coating systems, or VOC-free systems can be used from the outset. Here it is possible to use water-dilutable coating systems (such as the protective coating ELPEGUARD SL 1305 AQ-ECO) and cleaning systems (such as ELPESPEC R 5888), or to choose systems with a 100 % solids content. With a solids content of 100 %, solvent / VOC emissions can be avoided. However, established solvent-based protective coating systems sometimes have a VOC content of 40 to 80 %.

The curing process required after painting can also be made more environmentally friendly. Oxidative curing protective coating systems are usually physically dried in a continuous oven. Although the subsequent oxidative curing can take place at room temperature, in practice it is usually shortened by storing the oven for several hours in order to increase productivity. The energy consumption for operating these ovens is correspondingly high. UV-curable protective coating systems are solvent-free and require considerably less energy during the curing process than conventional drying. However, lamps with environmentally harmful mercury content are used in this UV curing process. This led to the further development of UV-curing protective coating systems for electronics, which are cured using UV LED systems. Protective coating systems are now available that can be cured using special UV LED systems. Here, light with a very narrow wavelength range is emitted, which cures the coating systems. The energy efficiency is significantly higher, as the LED emits (almost) no heat, and the service life of the LEDs is also longer than that of conventional lamps. The narrow waveband of the UV LEDs also means that no harmful ozone is produced.

The new ELPEGUARD thick-film coating Twin-Cure DSL 1602 FLZ/400 has been specially developed for UV LED curing at a wavelength of 395 nm. The coating cures in seconds at an energy of 1500 mJ/cm² and a power of 1500 mW/cm². It is adhesive-free after UV curing and can therefore also be used inline. Curing in shaded areas such as underneath components takes place reliably at room temperature by reaction with air humidity. This thick-film coating combines the properties of a polyurethane system with fast UV LED curing of unsaturated polyacrylates in a single-component copolymer that is characterized by high resistance under mechanical, chemical and climatic stress as well as under extreme temperature changes. -vk-

www.peters.de