Machine manufacturers are always coming up with interesting innovations that are presented at the 'productronica' trade fair. But it will be some time before the next 'productronica' (November 2023). In the meantime, PLUS asks how these innovations are being received by EMS providers - and what they expect from upcoming machines. And a used machine dealer spills the beans.

"The boss sends his apologies - a new container has arrived." It's not that easy to get Thorsten Düvel from TWD 'on the line'. The company, based in Leimberg near Aachen, deals in used machines for PCB assembly and has more than 28 years of experience in buying and selling these systems. This made TWD Managing Director Thorsten Düvel the perfect person to talk to for our special issue. Especially in the bumpy market situation - characterized by poor component availability, raw material shortages, high energy prices and supply chain disruptions - assessments from a supplier of used machines are of interest. If machines have to be replaced today, buyers often have different requirements than in the past. But what do the buyers of such machines expect - from their manufacturers, and what do the assemblers in particular expect?

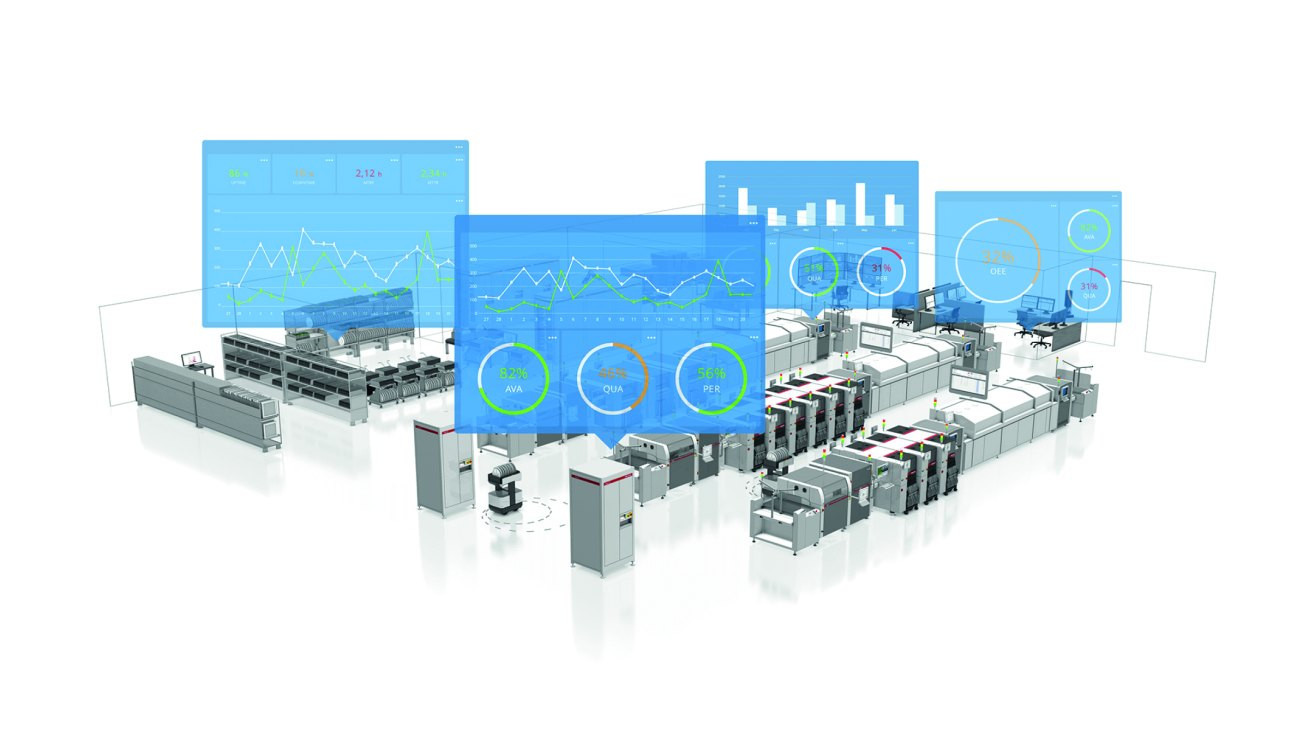

Traceability has become an integral part of electronics production (Image: Critical Manufacturing)

Traceability has become an integral part of electronics production (Image: Critical Manufacturing)

We hoped Thorsten Düvel would provide answers to these questions. Weeks passed before a phone call was made - PLUS had to give way to incoming containers at TWD. "The demand has not decreased, it has remained the same," explains Düvel in conversation. However, his customers are placing more and more value on systems "that don't have such high power consumption". It is clear that energy costs must also be reduced in the EMS sector. At the same time, tried-and-tested machines are valued due to their reliability and known application possibilities.

At TWD, incoming machines are thoroughly dry ice-cleaned and reconditioned. According to Düvel, vacuum vapor phase systems in particular are desperately sought after. Special dispensers, small transport systems and flip stations are also very popular purchases. However, according to Düvel, one thing is clear: "The situation is forcing customers to be cautious, they want to wait and see how the situation develops before investing." Also because of the Ukraine conflict. The uncertainty is palpable.

Otherwise, demand differs between large customers and small EMS service providers. "Large customers are going for high volume, smaller ones need to be flexible above all." Demand in Germany also tends to be for individual machines, while entire lines are supplied abroad, for example to Portugal, the USA or a German production plant in Taiwan.

Andreas Kraus, Kraus HardwareWhenasked what innovations his customers are looking for in new machines, Düvel emphasizes one point in particular: "Machines have to offer a high degree of flexibility, especially today: fast programming from CAD data, rapid recording and description of components." As far as traceability is concerned, the data depth of today's machines is enormous according to Düvel ("It's crazy how much data can be read out."). However, additional interfaces between machines are often desired so that modules from different manufacturers can communicate even better with each other - especially when transferring transport systems.

Andreas Kraus, Kraus HardwareWhenasked what innovations his customers are looking for in new machines, Düvel emphasizes one point in particular: "Machines have to offer a high degree of flexibility, especially today: fast programming from CAD data, rapid recording and description of components." As far as traceability is concerned, the data depth of today's machines is enormous according to Düvel ("It's crazy how much data can be read out."). However, additional interfaces between machines are often desired so that modules from different manufacturers can communicate even better with each other - especially when transferring transport systems.

When asked what he expects for the machines in the future, Düvel is cautious. "Perhaps assembly with laser technology for small, flexible productions. Or loading with hot air." He looks forward to such innovations with curiosity. After all, the machines of tomorrow are the used machines of the day after tomorrow.

What innovations are EMS providers hoping for from new machines?

We also asked some EMS service providers how they assess current developments in machines and production systems. Joachim Taube (Development & Operations Management at RAFI) paints a positive picture: "The automation of standard processes is relatively advanced. In the future, solutions for optical inspections with the help of A.I., semi-automated changeover processes for product changes and the further automation of inspection and assembly processes will be interesting." He would also like to see a high degree of flexibility in new machines: "Automation is often only worthwhile for larger quantities. Automated production of medium and small quantities also requires automation solutions that are easy to set up and can be operated reliably and safely." The feeding of material and transportation of the assemblies posed a particular challenge here.

This coincides with the wishes of Matthias Sester, Managing Director of Fritsch Elektronik. "We rely on two different machine types: ASM, to be able to fulfill high-volume orders, and MYDATA, because it makes you highly flexible. Unfortunately, I haven't found a machine that combines both: High flexibility and high-volume capability." The stuttering component availability of the last two years has proved Fritsch right to cover both properties equally: "You often wait six months for certain components. In most cases, either all of them arrive at once or nothing at all. You also often no longer receive materials on a roll, but rather belt sections - we call them 'snippets'. Any EMS service provider that has the ability to process this in a cost-efficient way is one step ahead."

According to Sester, the situation has become more difficult due to the market situation: "When a component is available, I have to be ready for the customer. This must also be reflected in the machine environment. Little has happened in the last three years, we get little support from the machine world." Future machines will have to better combine flexibility and volume capability. Sester also clearly states what this desired flexibility means for him: "Dealing with the variety of components and better handling. Because in the past, everything was always available. That has changed."

"We need full access to machine and production data"

With regard to the important aspect of traceability, Sester notes - quite critically - that machine manufacturers place little value on uniformity: "This is an operational policy decision. They want to sell their own software." He would like to see more transparency - and a certain degree of standardization at machine level: "That would make things easier for everyone. Machine manufacturers should remember: as an EMS provider, I choose a machine precisely because it offers transparency."

For Joachim Taube (RAFI), traceability is "indispensable in electronics production." A transparent representation of the current production situation is the basis for stable processes and optimization. "Overall equipment effectiveness (OEE) is a classic key figure here, which is made up of quality, availability and performance," says Taube. His company offers a data collection system for this and also uses it itself. "KIS.ME (Keep it simple. Manage everything) is a simple solution for connecting manual processes or existing systems without interfering with the machine control system and digitizing process data."

Marc Lauter from KATEK (Group Head Technology) is largely positive about current developments in machines for EMS assembly: "The trend towards optimizing production processes is continuing. The widespread introduction of small, intelligent and easy-to-program robots with measuring and camera systems is to be welcomed. It will relieve the burden on workers and the high degree of automation will improve quality." The increased use of AGVs (automated guided vehicles) for in-house logistics processes will also relieve the burden on employees, who will then be available for other activities.

In his eyes, machine manufacturers are already giving a lot of thought to how processes can be simplified and optimized. However, Lauter also notes: "More flexibility would be desirable, especially for manufacturers from Asia, for example when it comes to software adaptations." Many things simply take too long and some ideas are not implemented at all. One thing is certain: customers expect more flexible designs from future machine innovations, "layout options that enable the assembly of alternative components and designs." KATEK is therefore working intensively with machine and system manufacturers to drive these developments forward. In terms of traceability, KATEK is working on a standardized software solution for all hardware and software.

For Andreas Kraus (Managing Director of Kraus Hardware in Großostheim/Ringheim), improved traceability is also an important aspect of machine innovations. "We need full access to machine and production data in order to process it in our IT system with the other production data." It is convenient to be able to access the machine's database directly or if appropriate interfaces are available. But Kraus also has more pragmatic wishes for machine manufacturers: "Competent support and contact with the manufacturer in the event of technical problems, new options and even adaptations to machine hardware and software. And preferably before the purchase, otherwise it can be painful and expensive. The support provided by dealers has often failed to convince us, which is why we usually buy the machines directly from the manufacturer." And, of course, a "good and fast supply of spare parts, if necessary up to the service call, should this be necessary - at fair prices." This is not necessarily the case at the moment.

For future machines, Kraus hopes above all for fast set-up and changeover times and the resulting short downtimes. However, flexibility is also the most important thing for Kraus Hardware: "We need the widest possible range of options in order to meet the diverse challenges in the field - without compromising on production quality, of course."

www.rafi-group.com, www.katek-group.de, www.fritsch-gmbh.de,

www.kraus-hw.de, www.twdgmbh.de, www.criticalmanufacturing.comwww.kraus-hw.de , www.twdgmbh.de, www.criticalmanufacturing.com