With GreenTin+, Feinhütte Halsbrücke GmbH is setting an economic and ecological milestone: using an energy-saving full recycling process, the experts obtain high-purity tin or electrolytically purified alloys from dross, ash, runners, sludge, chips or solder pastes in pyro- and hydrometallurgical plants. "With a purity of 99.99%, the tin GreenTin+ obtained with our recycling processes clearly surpasses the quality of imported tin from primary raw materials," emphasizes Tobias Patzig, authorized signatory of Feinhütte Halsbrücke GmbH.

Recycled tin offers a number of other advantages, such as independence from international supply chains. In addition, the sustainable recycling of tin not only significantly reduces the energy input. The process reduces mining exploitation and the processing and smelting of ores to a minimum. CO2 emissions can thus be significantly reduced by up to 98.9% per tonne of tin and the general negative impact on the entire ecosystem can be significantly reduced. But recycled materials also do justice to humanitarian sustainability. Finally, the extraction situation in tin mines is playing a role for more and more companies.

Unlike other raw materials such as paper or plastic, metals can be recycled as often as required without any loss of quality and can be reused without restriction. This means that the origin of the material does not necessarily say anything about its purity or quality. Rather, the decisive parameters here are the type and scope of the processing steps, the know-how involved and the performance of the units. "We can draw on centuries of experience, modern facilities and optimized production processes. As a result, our metals and alloys, which are obtained from a wide range of recycling processes, are of a quality that is in no way inferior to that of primary raw materials," emphasizes Patzig.

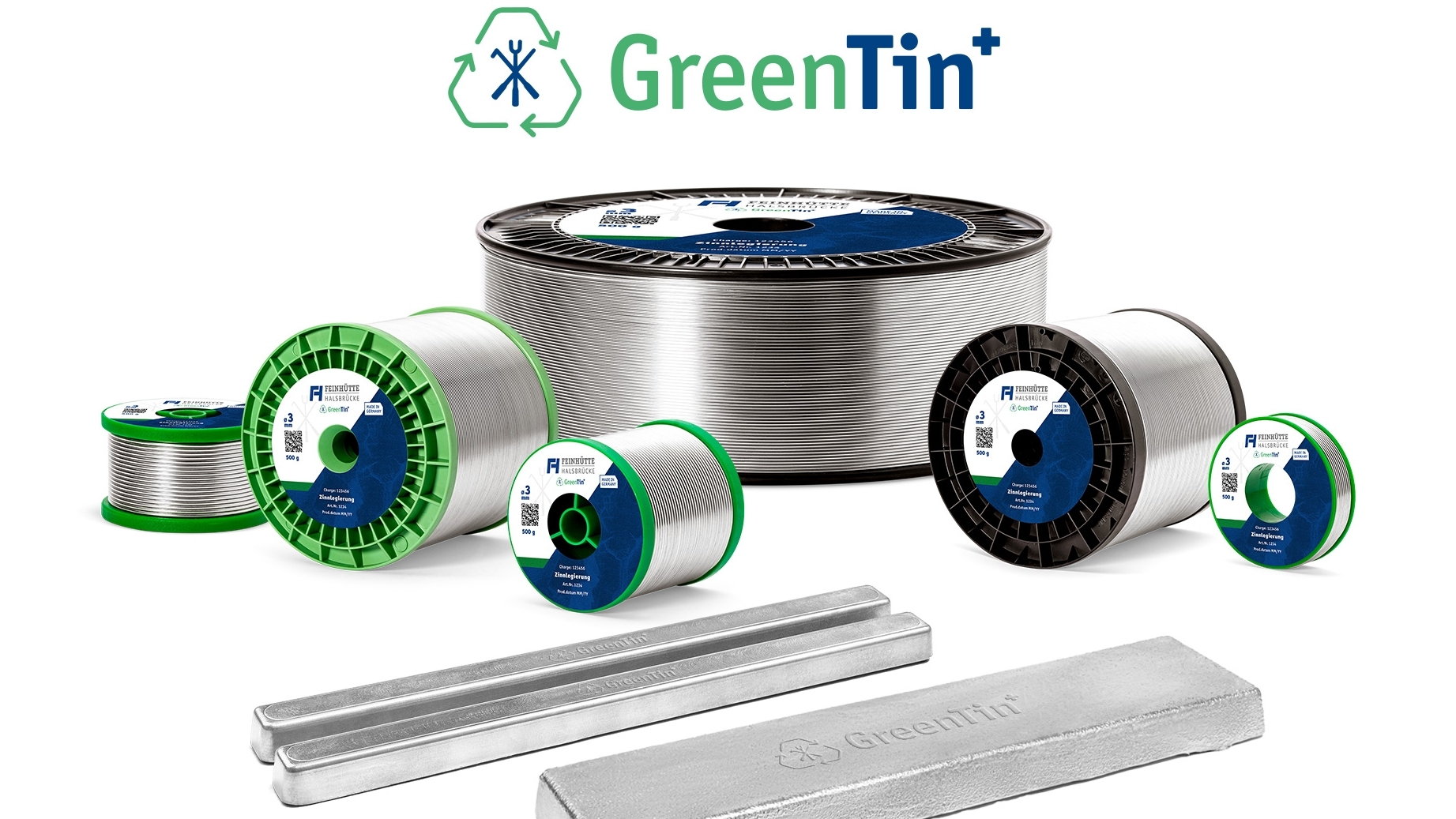

GreenTin+ is offered as wire, ingots, bars, bulk material or similar. The quality of the recycled metal, which is well above the general market standard, is suitable for the manufacture of extremely high-quality products, such as those required in electronics production for consumer electronics. In addition, Feinhütte Halsbrücke is the first tin manufacturer in the world to be able to provide certified proof of the use of 100% recycled material. "We are sending another important signal to the market with the ISO 14021 certification that our customers have recently requested," says Patzig.