AT&S has developed a concept for virtual audits in which customers or partners do not have to be physically present on site, but can visit the plant virtually thanks to technical aids such as VR glasses and video transmission.

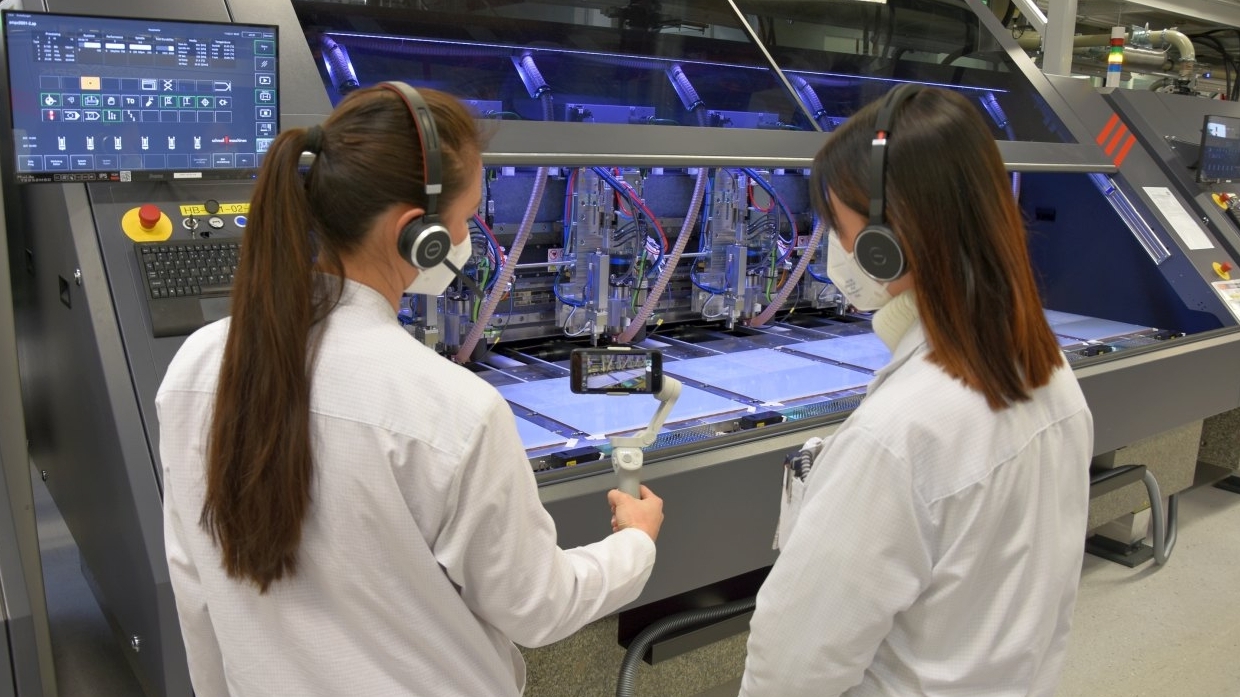

With the help of a helmet camera or smartphone camera, technicians show the customer the key production steps in PCB manufacturing online as they walk through the production hall. Audit participants can be individually connected via a collaboration tool, communicate with each other and the auditor can access all documents in the shortest possible time and is continuously networked with all those responsible.

"Restricted travel options and protective measures in the plants have now made it almost impossible to carry out on-site audits," says Michael Monschein, Head of Corporate Quality Assurance at AT&S. However, the coronavirus pandemic has reinforced trends that have been emerging for years. The Austrian manufacturer is therefore certain that this form of audit will continue to be used even after the pandemic.