In 2022, automotive supplier BIA put one of the most modern electroplating lines in Europe into operation at its main plant in Solingen. The background to the complete new build was the modernization of the plant technology and the integration of new, efficient production techniques.

This also includes the conversion from conventional chromium(VI)- to modern chromium(III)-based coating processes. However, these are not only more expensive due to the large number of additives required, but also pose a greater challenge for wastewater treatment. In the treatment processes established to date, a large proportion of the valuable substances used in the electroplating baths are currently lost - a circumstance that places an additional burden on the economic efficiency of the chromium(III) processes.

New expansion of water treatment

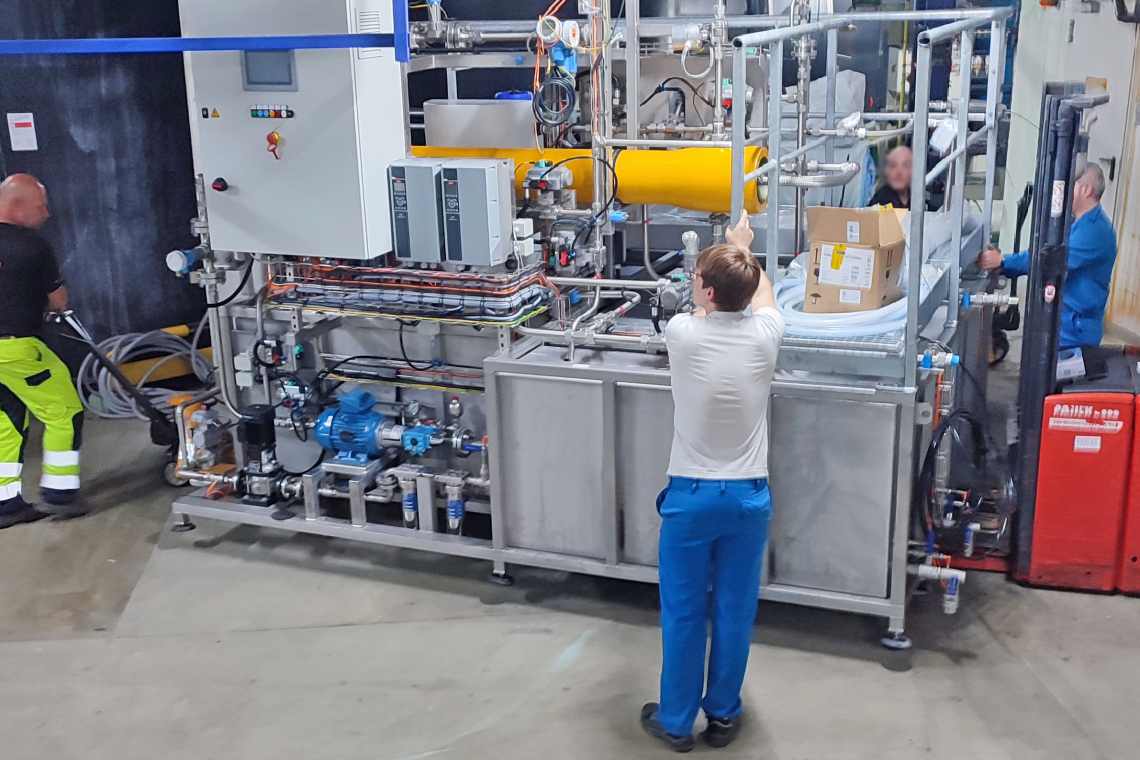

BIA has now installed a pilot plant that recovers almost all of the valuable materials when treating the chromium(III) rinsing water. These are then fed back into the electroplating process. The treated water can then also be reused in the process and thus close cycles within the process. The development of the plant was a joint project between the Technical University of Birmingham, the TH Cologne, the NCSR Demokritos in Athens, BIA Development and Process Technology and the plant manufacturers Nijhuis Saur Industries and Salinity Solutions as part of the European research funding project IntelWATT.

The new chromium(III) wastewater treatment system at BIA uses the principle of reverse osmosis.

The new chromium(III) wastewater purification system at BIA uses the principle of reverse osmosis. Although this process is tried and tested and has been known for a long time, it has never been used on an industrial scale to purify electroplating rinsing water. It is expected that this will result in the almost complete recovery of all valuable substances dissolved in the rinsing water, which can then be fed back into the process. BIA expects this to have an economic and ecological effect. As a positive side effect, the loss and consumption of process water will also be reduced.

The new water treatment plant is now in trial operation and is initially only cleaning the chromium(III) waste water from an electroplating plant. If the concept proves to be efficient as expected, BIA will also transfer it to the other plants at all BIA production sites worldwide. In the long term, the new wastewater technology offers considerable potential for improved recyclability, resource conservation and cost-effectiveness for the already expensive chromium(III) coatings.