Trimet Aluminium SE has developed a new aluminum alloy. The wrought alloy trimal®-52 meets the highest requirements in terms of strength and deformation capacity. With this latest innovation, the aluminum specialist is expanding its product range for lightweight automotive construction.

The new aluminum alloy trimal®-52 (AlMgSi) meets the highest requirements for structural components in vehicle construction. Trimet has developed the wrought alloy from the 6xxx family. Alloys from this series are established materials in automotive engineering. With strengths of more than 305 megapascals and a yield strength of more than 280 megapascals, trimal®-52 is suitable for structural components that require not only corrosion resistance but also the best crash properties and maximum strength.

"The conversion of the automotive sector to battery drive opens up new areas of application for aluminum and at the same time places new demands on the material," says Thomas Reuther, Member of the Executive Board of Trimet Aluminium SE. "Our new alloy not only scores points for its outstanding material properties, it is also easy and flexible to process."

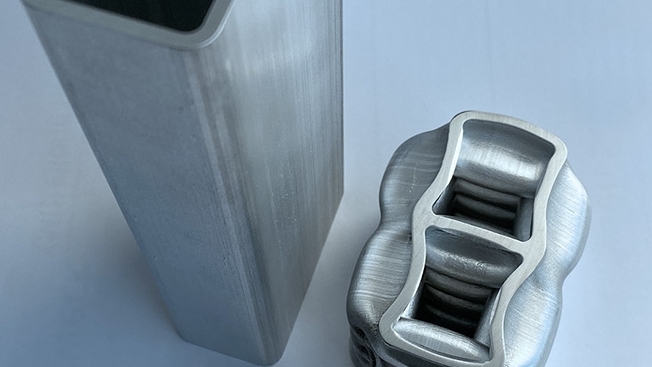

The outstanding properties of trimal®-52 include an elongation at break of more than ten percent. The material is easy to press and can be recycled without any problems. The profiles produced from the alloy can also be thermally or mechanically bonded with other materials, for example cast nodes. The trimal®-52 alloy is particularly suitable for extruded profiles in accordance with the delivery specifications of automotive OEMs, especially for components with crash requirements and a yield strength of 280-320 MPa.