Fraunhofer researchers from Chemnitz, Görlitz, Aachen, Stuttgart and Halle (Saale) are working to reduce the cost of producing electrolysers for green hydrogen by more than a quarter in a new large-scale research project. Together, they are building a reference factory in which new production processes can be developed and tested over the next four years. The best and most economical processes will be reproduced in parallel in a completely virtual form and transferred to a technology toolkit, which will allow industrial companies to check exactly what production costs they can expect for certain types of electrolyser before planning production. The project contributes to achieving the climate targets and strengthens Germany as a business location. The German government is therefore funding it with 22 million euros via the hydrogen flagship project "H2Giga".

Hydrogen is an important building block in the conversion of industry and transport to renewable energies. In order to produce it at market prices and in a climate-neutral way, electrolysers - in which water is split into hydrogen and oxygen using electricity from wind or sun, for example - must be produced automatically in large numbers. With the technologies available to date, mass production would be far too expensive and uncompetitive. This is where the reference factory comes in. Research into cheaper materials, the quality of components, durability, better production technologies, the scalability of production processes, their automation, the networking of production lines, the development of efficient supply chains and factory planning should make large-scale production profitable. Production costs for water electrolysers in the gigawatt range are expected to fall by more than 25 percent.

Digital twins: Innovation pool reduces investment risk

The best and most economical production processes are recreated virtually for an innovation pool. These are known as "digital twins". They allow production processes and the combination of new production systems to be calculated and thoroughly tested on the computer. "We are building a digital library of future-proof electrolyser production processes that can be used to determine the investment costs and even the return on investment in advance, depending on the planned production volume, vertical range of manufacture and production variant," says Dr. Ulrike Beyer, Head of the Hydrogen Task Force at the Fraunhofer Institute for Machine Tools and Forming Technology IWU and coordinator of the large-scale research project. "The resulting technology kit will give the electrolyser industry a real boost. We are expecting an enormous innovation impact - also because our open-technology approach allows us to constantly integrate new ideas and concepts from industry and science."

Technology leadership strengthens business location

The Fraunhofer researchers are convinced that the best way to quickly make green hydrogen widely applicable is to establish its production as a competitive business model. However, there are currently still too few electrolyser manufacturers on the market and they tend to serve niche markets with small quantities. A strong domestic market for hydrogen technologies is still lacking. Technological leadership in this industrial sector can help to develop such a market. This would further strengthen Germany as a business location - also in terms of exports.

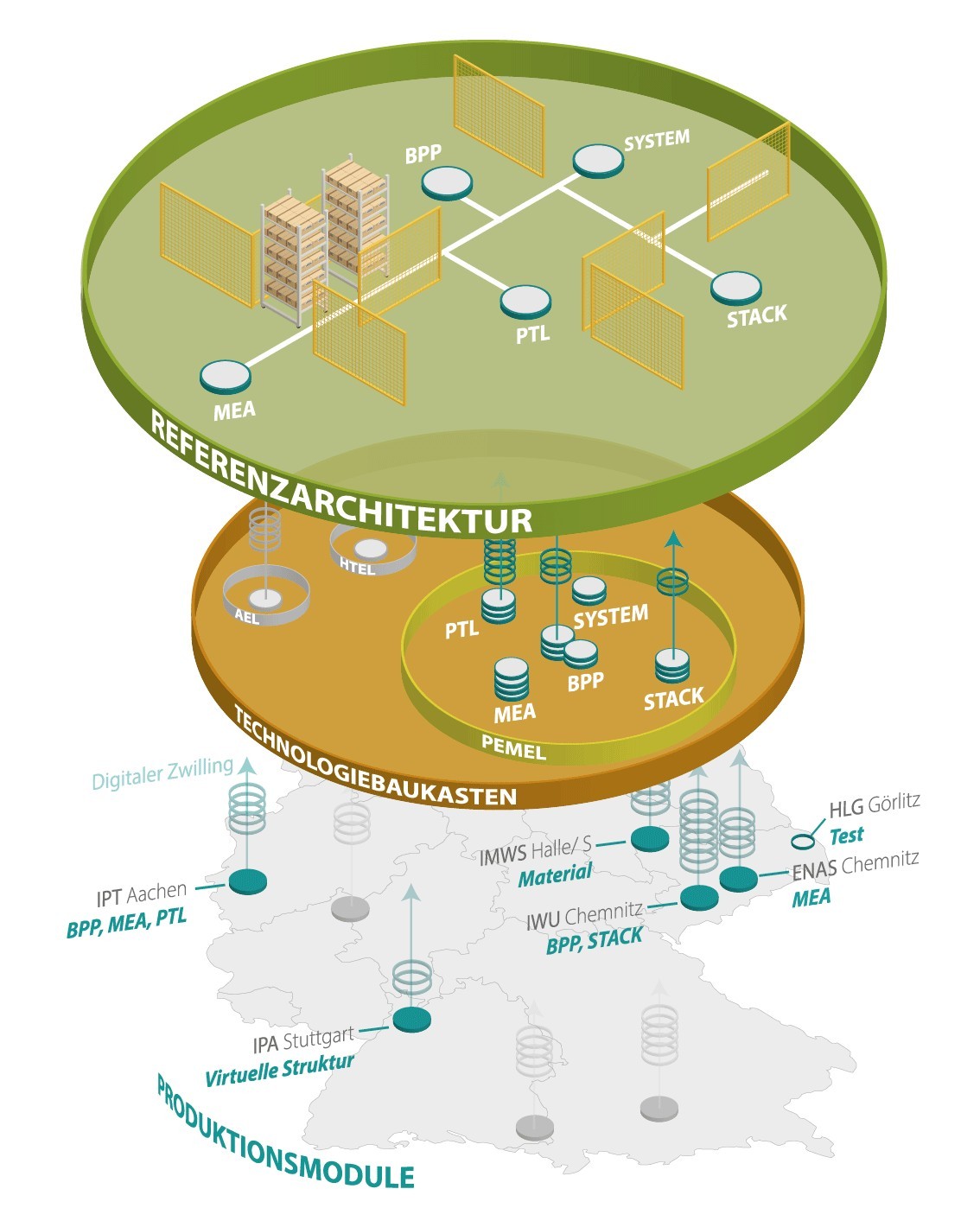

Germany-wide large-scale research project: structure and key elements of the reference factory © Fraunhofer IWU

Germany-wide large-scale research project: structure and key elements of the reference factory © Fraunhofer IWU

22 million euros for five Fraunhofer Institutes

In addition to Fraunhofer IWU, four other institutes of the Fraunhofer-Gesellschaft are contributing their expertise: The Fraunhofer Institute for Production Technology IPT in Aachen, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart, the Fraunhofer Institute for Electronic Nano Systems ENAS in Chemnitz and the Fraunhofer Institute for Microstructure of Materials and Systems IMWS in Halle (Saale). Together, they will receive funding of 22 million euros until 2025 from the German government's hydrogen flagship project "H2Giga". It comprises a total of 30 alliances and 130 industry and research partners.

The Fraunhofer IWU in Chemnitz is contributing research into rolling processes for bipolar plates (BPP). The new multi-pass rolling process will ensure that the channel geometries are applied to the anodes and cathodes in a quality-compliant manner. The aim is to achieve high-rate production. This will provide a manufacturing process for the ramp-up of electrolyser production that can deliver the corresponding BPP quantities for series production. By linking functionalization with the forming process using electron beams, it will be possible to insert microstructures to increase the service life and improve the efficiency of an electrolyser. In addition, the subsequent quality control will be further developed. Stacking, i.e. the close stacking of bipolar plates, should also be possible at a higher frequency and with a higher degree of automation. The quality of stacks produced in this way will be tested in the "Fraunhofer Hydrogen Lab Görlitz", which is currently being set up, and in the "Fraunhofer Hydrogen Center Görlitz".

The Fraunhofer IPT 's contribution includes research into new production technology solutions for the manufacture of catalyst coated membranes (CCM), porous transport layers (PTL) and bipolar plates. For CCM production, production facilities are being researched and set up which, on the one hand, allow a cost reduction for the production of a CCM via established process steps and, on the other hand, enable novel production processes such as direct membrane coating. The focus of the research work for the PTL and bipolar plates is on the development of production processes for integrated components for distributing the fluids inside the electrolyser. "Our aim is to achieve a reduction in component costs while simultaneously increasing performance through an overall architecture that is suitable for production," says Dr. Christoph Baum, Managing Director of the Fraunhofer IPT.

The Fraunhofer IPA will map the individual production modules of the reference factory, which will be set up at the participating institutes, as digital twins based on the concept of the administration shell and virtually network them to form a complete production line. To this end, a research team led by Joachim Seidelmann, Head of the Competence Center Digital Tools in Production at Fraunhofer IPA, is setting up a cross-location, service-oriented production IT platform. The basis for this is the Fraunhofer Edge Cloud platform. "To ensure that the exchange of information between the production modules runs as smoothly as possible and that all data can be consistently recorded and evaluated across the distributed locations, we plan to provide all systems, (sub)products and many production aids with an administration shell," says Seidelmann. "The main work lies in the development of the specific sub-models of the administration shell for hydrogen production, which describe the properties and characteristics in detail."

In the large-scale research project, Fraunhofer ENAS is working on qualifying the digital inkjet printing process as a CCM manufacturing process in order to achieve a highly productive, industrial process speed. The Catalyst Coated Membrane (CCM) is a central component of electrolyzers. The project goals include process savings of 33 percent and material savings of 3 percent. Overall, the aim is to reduce the manufacturing costs for CCM production by 30 percent compared to the current state of the art. Dr. Ralf Zichner, head of the Printed Functionalities department at Fraunhofer ENAS, explains: "With the highly productive use of digital inkjet printing technology from Fraunhofer ENAS for CCM production, two out of six process steps are eliminated compared to the state of the art."

The Fraunhofer IMWS focuses on the characterization of electrolyser components and systems, which makes it possible to identify potential weak points and defects in industrial use at an early stage. The aim is to reduce costs for test procedures, optimize fault tolerances and the service life of production elements and achieve shorter development times. "With our expertise in high-resolution diagnostic procedures and the possibilities in the Hydrogen Lab Leuna, we can make decisive contributions to the evaluation and optimization of electrolysis components," says Dr Sylvia Schattauer, Deputy Director of the Fraunhofer IMWS.

Details on funding from the "H2Giga" hydrogen lighthouse project

With its largest research initiative on the energy transition to date, the Federal Ministry of Education and Research (BMBF) is supporting Germany's entry into the hydrogen economy. The three hydrogen flagship projects are the result of an ideas competition and represent a key contribution by the BMBF to the implementation of the National Hydrogen Strategy. Over a period of four years, they are intended to remove existing obstacles that are hindering Germany's entry into a hydrogen economy. This involves the series production of large-scale water electrolysers (H2Giga), the production of hydrogen and derived products on the high seas (H2Mare) and technologies for the transportation of hydrogen (TransHyDE). More than 240 partners from science and industry are working together in the hydrogen flagship projects. The projects were launched in spring on the basis of non-binding funding prospects. The total funding will amount to over 740 million euros.