Together with scientists from the Paul Scherrer Institute (PSI), Empa's X-ray specialists are now also offering their industrial partners access to state-of-the-art material analysis of 3D printed workpieces. To this end, Empa recently became a member of the "ANAXAM" technology transfer center in Villigen.

Membership of the ANAXAM technology transfer center, which was initiated in 2019 by the Paul Scherrer Institute (PSI), the University of Applied Sciences Northwestern Switzerland (FHNW), the Swiss Nanoscience Institute (SNI) and the Canton of Aargau, promotes the exchange of experience among researchers in the growing field of additive manufacturing. Above all, however, industrial companies now have access to important additional analytical equipment - an important factor in staying ahead of the game when it comes to quality control in 3D printing.

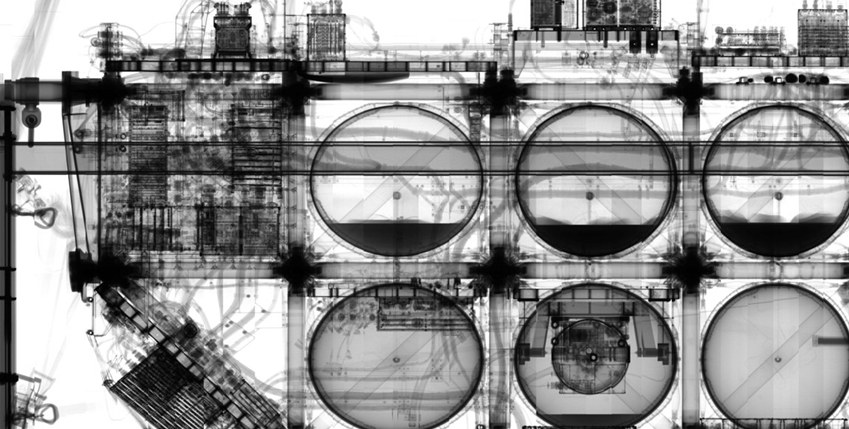

X-ray tomography for heavy and light objects

Three Empa devices are likely to be of particular interest to developers of 3D printing solutions. In the Linac high-energy X-ray tomograph, which is particularly suitable for large workpieces, workpieces up to 70 centimetres in diameter and up to 2 meters high can be examined. The X-rays penetrate steel up to 35 centimeters thick. X-ray images of samples made of reinforced concrete are also possible with this device without any problems. At the other end of the scale is the RX X-ray tomograph, which can produce images with a resolution of 0.6 micrometers. This means that even the smallest material defects can be detected. Empa's phase-contrast X-ray devices are particularly suitable for lightweight materials, such as plastic components, which only show low contrasts in X-ray light. Thanks to a special analysis of the scattered X-rays, resolutions of up to one micrometer can be achieved with this new method.

The EURECA satellite for X-ray examinations was delivered to Empa in August 2016 (Image: Empa)

The EURECA satellite for X-ray examinations was delivered to Empa in August 2016 (Image: Empa)

The equipment available at Empa's X-ray center is supplemented by the Empa platform for image analysis, which uses highly developed image processing methods to make the information in the two- and three-dimensional X-ray scans accessible. And with training courses for industry, Empa's experts ensure that the analytical methods are used safely and effectively.