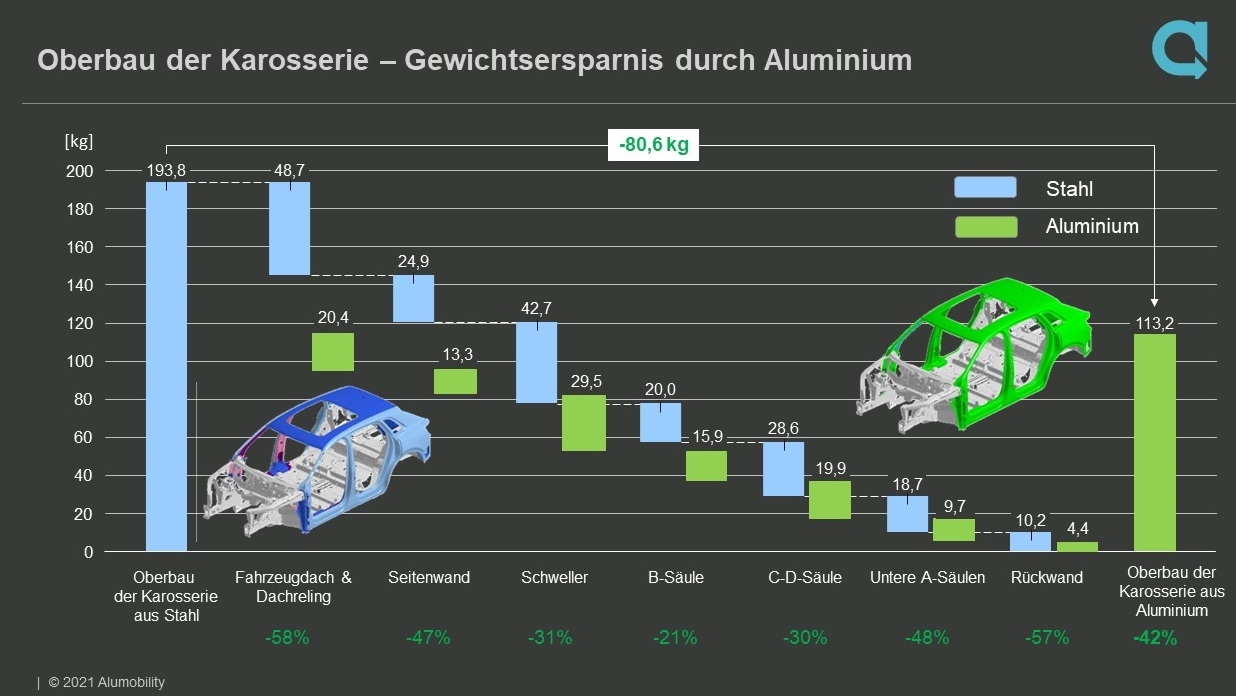

Every kilogram counts: With the rapid shift towards electromobility, consistent lightweight construction in the automotive industry is a higher priority than ever before. The latest study by the non-profit organization Alumobility shows in detail how much weight can be saved in modern car body production through the use of aluminium. Using the example of the current Audi e-tron® electric SUV, the study presented at this year's EuroCarBody conference shows that the use of the versatile lightweight metal in the superstructure of the body, the so-called top hat, can reduce weight by more than 80 kilograms. While the design in conventional HSS, AHSS and other steels weighs around 193.8 kilograms, the same components made entirely of aluminum only weigh around 113.2 kilograms - a difference of 42 percent.

Calculated for the entire body structure, including the doors and the steel platform, the weight drops from 481 to 399 kilograms, which is still around one sixth of the weight of the version with the usual steel content of around 80 percent (the results of the Alumobility study can be found at the following link: https://alumobility.com/technical-studies/chapeau-aluminum-top-hat-offers-lighter-alternative-to-the-steel-reference).

"Our latest research shows that aluminum offers a sustainable alternative to steel for the upper part of the vehicle body in automotive manufacturing," says Mark White, Executive Director of Alumobility. "In addition, the aluminum upper body can meet or exceed all required performance criteria with the same dimensions as steel. The weight saving leads to lower fuel consumption and lower emissions in vehicles with combustion engines, while the driving performance and range of electric vehicles are improved or the battery can be more compact."

Weight reduction in detail: every aluminum component contributes to savings

In terms of weight, the vehicle roof and roof rails offer the greatest savings potential using the Audi e-tron® as an example: replacing steel with aluminum here reduces the weight from 48.7 kilograms to 20.4 kilograms, which corresponds to a reduction of 58 percent. The sills save 13.2 kilograms or 31 percent, followed by the side panel (11.6 kilograms; 47 percent), the lower part of the A-pillars (9 kilograms; 48 percent), C- and D-pillars (8.7 kilograms; 30 percent) and the rear panel (5.8 kilograms; 57 percent). Depending on the aluminum grade, the B-pillars also contribute between 4.1 and 7 kilograms to the weight reduction (21 and 35 percent respectively).

Versatile aluminum: sustainable alternative saves time and money

Further results of the Alumobility study: aluminum can reduce the number of components and connections required and thus simplify the production process. This is achieved through the carefully coordinated combination of different aluminum alloys and the use of state-of-the-art forming and joining technology. In particular, an aluminum roof requires fewer components and connections than its steel counterpart, which reduces time and costs during vehicle assembly. This is achieved without compromising on performance and safety: the aluminum components meet or even exceed all the requirements in the car manufacturers' specifications.

Alumobility association is committed to pioneering automotive engineering

Alumobility was founded in January 2021 by the founding members Constellium and Novelis. The core task of the non-profit association is to conduct technical studies on the range of applications for aluminum body panels in automotive production. This summer, ARO, Atlas Copco and Sika also joined the association as specialists in innovative aluminum joining technologies.