Decades of experience show that measurements, especially in the refrigerant circuit, are time-consuming and complicated in research and test centers. Sampling is often difficult or not feasible. Therefore, the ratio between oil and refrigerant is often estimated in practice using indirect methods.

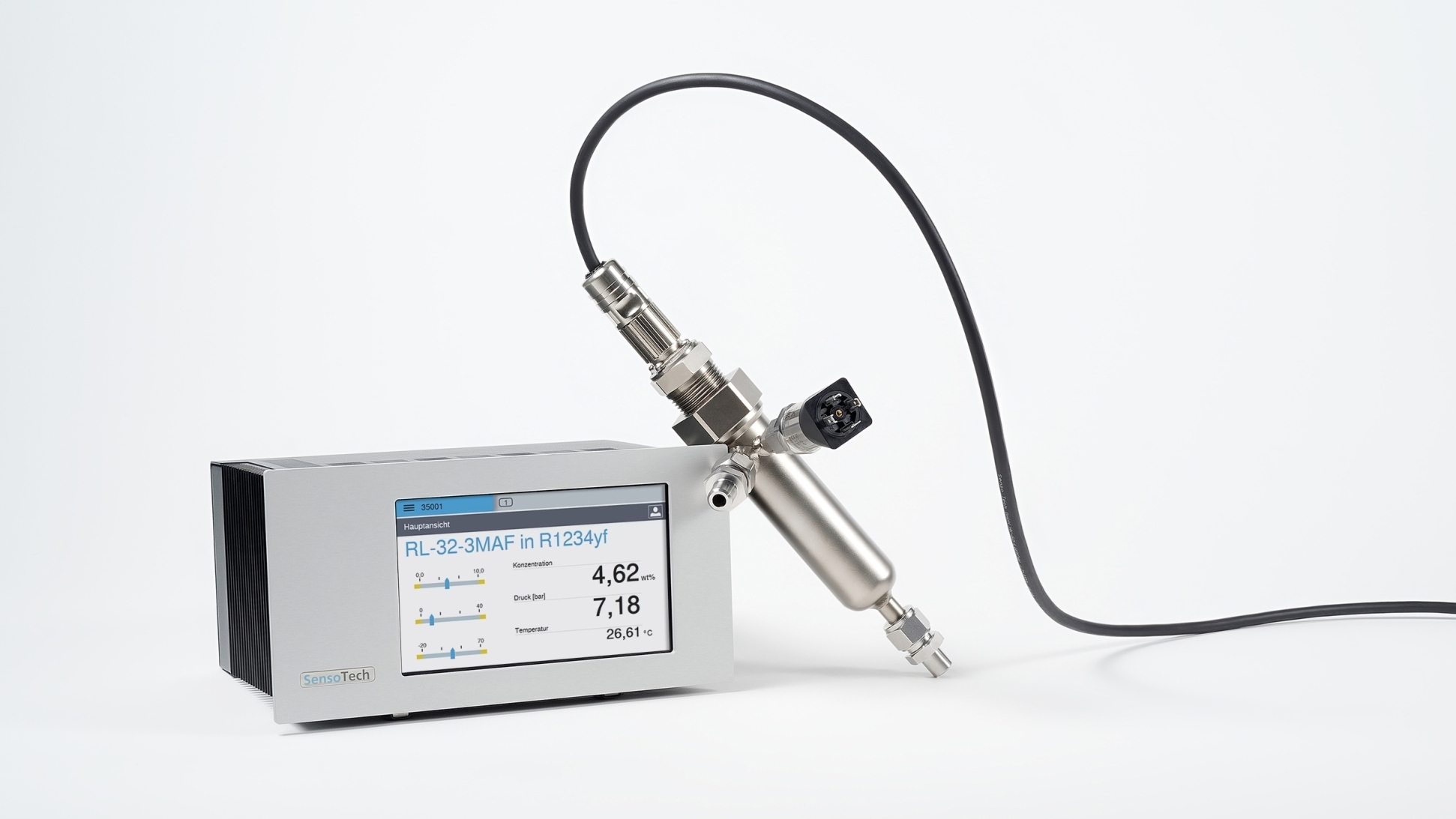

In order to carry out these measurements as precisely as possible, SensoTech has developed the inline solution LiquiSonic® OCR, which offers unbeatable advantages.

SensoTech attaches great importance to precise measured values when monitoring the oil concentration. The determination of the oil concentration is based on pressure, temperature and sonic velocity measurements in the liquid refrigerant. This measuring principle enables highly accurate and fast adjustment of the desired oil/refrigerant ratio.

Probably the greatest advantage of online oil condition monitoring in real time is the permanent availability of the measured values. As the data is updated every second, the user has precise knowledge of the oil/refrigerant ratio at all times. Time-consuming adjustment of the oil concentration and delayed measured values in the circuit are therefore a thing of the past.

Monitoring a wide range of refrigerants with one measuring device

SensoTech impresses with sustainable and comprehensive process solutions. Numerous product data sets (calculation models) can be stored in the controller of the measuring system. This makes it easy to monitor a wide range of refrigerants. Thanks to decades of experience and the manufacture of the measuring devices, there is almost no refrigerant left that has not yet been measured by SensoTech.

LiquiSonic® OCR also impresses users with its maintenance-free operation and comprehensive documentation options. The supplied process adapter ensures simple installation and immediate readiness for use. SensoTech thus offers a compact measuring system with a wide range of functions and options.