"Instead of growth, we need to focus on values!" - This mnemonic from BASF board member Saori Dubourg was taken home by the participants of the 30th Aachen Machine Tool Colloquium (AWK) on September 23, 2021.

More than 1,400 specialists and managers from the management levels of the manufacturing industry responded to the call from the Machine Tool Laboratory WZL at RWTH Aachen University and the Fraunhofer Institute for Production Technology IPT for the traditional network meeting: Following a postponement due to the coronavirus pandemic, the AWK was one of the first major face-to-face events to take place on site in Aachen and simultaneously as an online conference under the motto "Internet of Production - Turning Data into Sustainability".

The organizers' aim with AWK'21 was to spark a discussion on value in production technology: After the colloquium, initially planned under the heading "Turning Data into Value", had to be postponed twice, it was possible to focus the topic more strongly with a targeted view to sustainable value creation. The question of how companies can secure their future competitiveness through sustainable and resilient production ran like a common thread through all the presentations, discussions and exhibitions in the Aachen Eurogress and in the two host institutes.

The four leading figures in Aachen production technology, Professors Thomas Bergs, Christian Brecher, Robert Schmitt and Günther Schuh, see the current debate on social values and the resulting changes on the capital market - from a purely financial view of productivity to a stronger focus on the sustainability of products and services and the associated manufacturing processes - as the triggers for the urgently required turnaround in production. They cite the Internet of Production as the most important enabler of this production turnaround: the end-to-end digitalization and networking of machines and systems within the production and value chain.

Sustainability is already being practiced in various industries

As an example of the future of the metal industry, Professor Katja Windt from the SMS Group presented a path to decarbonized steel production. In her presentation, she gave an example of the links between reducingCO2 emissions through hydrogen technology and the digitalization of blast furnace processes, which could ultimately lead to new, hybrid business models.

Lars Wagner, COO of MTU Aero Engines AG, spoke about the potential that could arise from new and improved drive concepts in aviation. With the aim of being able to manufacture both conventional engine models and new, fuel cell-based engines, Wagner presented an excerpt from the company's digitalization strategy, ranging from AI-supported simulation to predictive maintenance. With a view to the rapid implementation of global climate targets, he emphasized the importance of close cooperation in innovation networks.

Focusing on value for the environment, society and the economy

Saori Dubourg, Member of the Board of Executive Directors of BASF SE, explained that sustainability must become "the new normal" - not least due to increased customer demand. Market demand, as well as political conditions such as the European Green Deal, will accelerate the trend and sooner or later drive companies towards transformation.

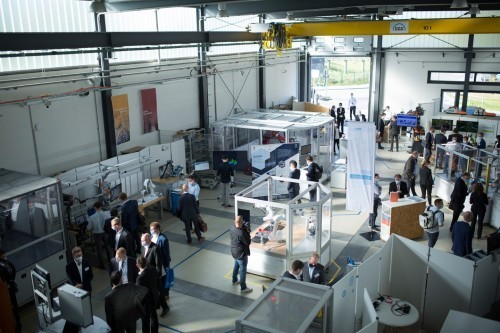

Research up close: sustainable production technologies and product developments in the new hall of the WZL at RWTH Aachen University.

Research up close: sustainable production technologies and product developments in the new hall of the WZL at RWTH Aachen University.

On the way to the future of sustainable production

"We are facing a production turnaround: How, where and what will we produce in the future?" said Professor Thomas Bergs, holder of the Chair of Manufacturing Process Technology at the WZL at RWTH Aachen University and member of the Board of Directors at the Fraunhofer IPT, summarizing the new key issues in production. According to Bergs, the sustainability of manufacturing process chains is becoming an essential evaluation parameter. "How must sustainable production cycles be organized in a global economy? And what regulatory mechanisms can and should there be to control resource consumption? There will undoubtedly be completely new products and production technologies." There is still a lot to be done here and conferences such as AWK'21 could help to get people talking about the conditions under which production could be organized in the future.

Both the Aachen researchers and the speakers saw potential solutions in digital technologies for networking such as edge cloud and 5G mobile technology, in artificial intelligence and the digital twin of product and production. These technologies are already in use in companies today and their further development is attracting a great deal of attention in production research.

About the Aachen Machine Tool Colloquium

The Aachen Machine Tool Colloquium is both a network meeting and an information hub. Participants from various disciplines traditionally meet in Aachen every three years to discuss the production of tomorrow. In addition to the usual face-to-face event, there was a premiere at the 30th Aachen Machine Tool Colloquium: In addition to the analog event in Aachen's Eurogress, large parts of the event program were broadcast digitally.

At the next AWK on May 11 and 12, 2023, industry and science will meet again in Aachen - working title: Technologies forCO2 Neutrality.