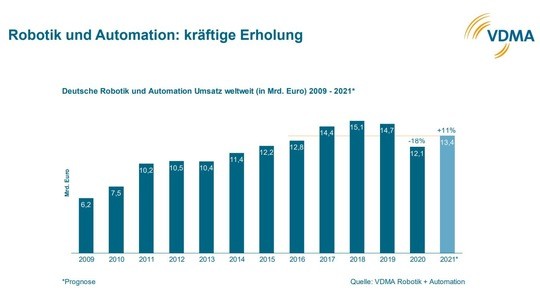

The robotics and automation industry in Germany will generate an 11% increase in turnover in 2021 with 13.4 billion euros - according to the forecast of the VDMA trade association R+A. Green technology strategies are important drivers of economic recovery. In contrast, 2020 was still clearly negative, particularly due to the coronavirus pandemic, although the decline in turnover in domestic and international business was more moderate than expected at minus 18%.

"The forecast for the current year shows a strong recovery and represents a positive turnaround for the industry," says Wilfried Eberhardt, Chairman of VDMA Robotics + Automation. "Order books in particular are currently filling up quickly. Even better sales figures are achievable if the current supply bottlenecks for key components are eliminated quickly. The outlook into 2022 is excellent, as complex projects that are currently underway will only be invoiced with a time delay. With the current momentum, the chances of reaching or even exceeding the record result from 2018 as early as next year are therefore good," explains Eberhardt.

A comparison of the three sub-sectors of Robotics + Automation

The three sub-sectors developed differently in 2020: turnover in robotics fell by 23% to 3.1 billion euros. Integrated Assembly Solutions recorded a 20% drop in turnover to 6.4 billion euros. The Machine Vision division lost a comparatively low 4%, with industry sales reaching €2.6 billion. Overall, turnover in robotics and automation fell by 18%.

"The forecast for the current year 2021 shows a strong recovery and represents a positive turnaround for the industry," says Wilfried Eberhardt, Chairman of the VDMA Robotics + Automation Association.

"The forecast for the current year 2021 shows a strong recovery and represents a positive turnaround for the industry," says Wilfried Eberhardt, Chairman of the VDMA Robotics + Automation Association.

Forecast 2021 - sub-sectors & overall

VDMA Robotics + Automation is forecasting the strongest recovery in sales for 2021 for the robotics sector with an increase of 15 percent - followed by integrated assembly solutions with an increase of 10 percent and industrial image processing with an increase of 7 percent. "For robotics and automation as a whole, we expect sales to increase by 11% in the current year," says Eberhard.

Impetus for the future

Demand for robotics and automation technologies is characterized by strong catch-up effects: Investments were postponed during the coronavirus crisis and are now filling the order books. The social transformation on the path to climate neutrality and the sustainable use of resources is also generating new business: robotics and automation are increasingly proving to be key technologies.

Here are three examples:

- In agriculture, low-cost field robots are helping to localize weeds using artificial intelligence and burn them with lasers in a targeted manner. Organic farmers halve their weeding costs with such an automation solution from IGUS in Cologne, while at the same time replacing chemical agents.

- The industry is relying on automation technology to produce fuel cells for hydrogen-powered cars in the future in a cost- and energy-saving way. INNOCISE, a company founded in Saarbrücken in 2019, is working with Schunk to offer innovative robotic grippers based on a principle copied from nature. They use bionic adhesive properties and do not require any external energy when gripping components. This significantly reduces energy requirements in production.

- High-performance batteries are a core technology for decarbonization - in the transport sector and in industrial production, in stationary storage technology and in the stabilization of power grids. Intelligent automation reduces production costs, which helps battery technology achieve a breakthrough in e-mobility and other areas. At the same time, the highly efficient production technology reduces the CO2 backpack.

Innovation "Made in Germany" - solar power plant

An impressive example of robotics and automation in the energy sector is currently the construction of one of the largest solar power plants in the world. The Constance-based company RCT Solutions is supplying production expertise and technology "Made in Germany" for this project. The experts from Lake Constance are helping the client and operator in Turkey, one of the country's largest construction groups, to decouple itself from international supply chains for solar panels. As a first step, a purpose-built Industry 4.0 factory in Ankara is producing 3.5 million solar modules. In a photovoltaic power plant in Konya, 260 kilometers away, these panels, which are manufactured in-house, will be installed directly after production. The aim is to generate 1 GW of electricity from solar energy in the final expansion phase - in the sixth largest solar power plant in the world. The investment volume is around 1.1 billion euros.

"In many European countries, people are currently thinking about rebuilding a complete photovoltaic value chain that includes all production steps," says Peter Fath, CEO of RCT Solutions.

"Turkey has now shown that it works. It has already created 1,400 new jobs at the factory in Ankara."

"The solar power plant in Konya shows where the journey is heading," adds Patrick Schwarzkopf, Managing Director of the VDMA Robotics + Automation Association. "The task now is to achieve the ambitious climate targets in reality. To do this, we need to scale up renewable energies and environmental technologies to unprecedented dimensions. Robotics and automation enable us to do this with the highest quality and competitive costs."

Outlook automatica sprint: June 22-24, 2021

automatica sprint, a new trade fair format in the automatica portfolio, will offer the robotics and automation industry a digital platform for exchange, knowledge and business this year. "The great response from the industry to the online format proves that we are absolutely meeting the special needs in the current times," says Falk Senger, Managing Director of Messe München. Over 80 leading companies are taking part in the digital trade fair format.

munich_i, a newly created platform for artificial intelligence (AI) and robotics, also offers great added value. The central element is the High-Tech Summit on June 22. Under the motto "intelligence empowering tomorrow", experts from science and business will discuss the interaction of human and artificial intelligence in the areas of work, health and mobility. Participation in the Hightech Summit is included in the ticket for visitors to the automatica sprint digital platform.