The fifth DeburringExpo took place at the Karlsruhe Exhibition Center from October 10 to 12, 2023. 107 exhibitors from 13 countries showed their products to 1204 visitors during these three days.

An experienced electroplating technician once said: "Pre-treatment is everything. Without careful pre-treatment, you will never get a good coating." Pre-treatment includes operations such as deburring, edge rounding, cleaning and surface finishing. And it is precisely these areas of surface technology that DeburringExpo covers. The diverse range of products and services presented by the exhibitors in Karlsruhe reflects the changing challenges facing manufacturing companies today. In addition, the leading trade fair for deburring technologies and precision surfaces offered a top-class supporting program with its bilingual specialist forum and various theme parks.

5th Leading Trade Fair for Deburring Technologies and Precision Surfaces

Clean components that are deburred as required and a precise, product-specific surface finish are among the quality-critical features of sustainable production. However, the tasks in these production areas have become more diverse and complex due to new and modified products in areas such as mobility, energy technology, semiconductor production, aerospace, medical and pharmaceutical technology as well as changes in production technologies and materials. In order to meet given specifications, appropriately adapted processes are required for deburring, edge rounding and cleaning as well as the production of precision surfaces.

- 1200 trade visitors

- 107 exhibitors

- Exhibitors from 13 different countries

- 500 participants at the specialist forum

Machines, systems and tools presenting solutions for quality assurance, automation and production integration as well as services reflected almost the entire spectrum of an increasingly important industry. "The diverse range of products and services is designed to master the various challenges such as improving quality, increasing productivity, cost-effectiveness, flexibility and resource efficiency and to strengthen the competitiveness of manufacturing companies," reports Hartmut Herdin, Managing Director of the private trade fair organizer fairXperts GmbH & Co.

Innovations in all areas

Machines and processes for deburring and cleaning components in a single step were also presented

The high quality of the future-oriented range is also based on the numerous new and further developments presented by the exhibitors. Among other things, the focus was on solutions for meeting and verifying ever stricter specifications with regard to deburring and surface quality as well as edge rounding. These include, for example, new systems and tools for manual and automated deburring and the production of precision surfaces. Machines and processes for deburring and cleaning components in a single step were also presented, whereby this can also be fully automated and integrated into production in a dry process. The spectrum of innovations also ranges from systems for processing precision parts in the sub-micrometre range to new solutions for vibratory finishing, ECM systems for deburring and as an alternative for shaping and component design through to process automation with self-learning robots and digitalization.

Raisins from the range

Deburring systems

The ADoC deburring system from Alpine Metal Tech is used for the fully automatic deburring of aluminum castings. In order to meet the high quality and surface requirements, the system is equipped with integrated inline measurement with line sensors. This corrects component deviations as well as clamping and casting errors from component to component and achieves a consistent deburring result. The deburring contour taught into a CAD/CAM system is calculated in the cell using the measurement data obtained and a new machining program is created for the milling robot.

With the new FlexJet HD high-pressure water jet deburring system, system manufacturer Karl Roll has developed an efficient solution for deburring and cleaning in a single work step. Flitter burrs and clamping chips can be removed just as effectively as welding beads and layers of paint and scale. Individually adapted nozzle systems ensure a high degree of workpiece flexibility combined with high precision for reproducible results.

AW Maschinen- & Anlagentechnik GmbH & Co KG describes its cryogenic deburring without nitrogen down to minus 40 °C as a world first. Traditionally, the burrs to be removed are embrittled by supplying liquid nitrogen and irradiated with granulate. However, the AW Technik process does not require nitrogen. At its heart is a granulate screw conveyor with a heat exchanger unit.

The inline-capable quattroClean power technology from acp systems AG uses recycled, liquid carbon dioxide as an abrasive processing medium. It is compressed inline into fine snow granulate, accelerated to supersonic speed by compressed air and blasted onto the surface to be processed. The deburring effect is primarily based on the mechanical force of the impinging granulate and the embrittlement of the burrs due to the strong cooling.

For manual deburring, Botzian & Kirch GmbH offers solutions with electric micromotors and pneumatic hand grinders, which are equipped with the appropriate precision tools depending on the task. In many cases, micromotors are convincing because they run extremely quietly at high speeds and have very good concentricity properties. Cobots are ideal for automated deburring. Four different models with simple operation and competitive prices are available.

Deburring tools

MD Drucklufttechtnik GmbH & Co KG presents a world first with its first electric drive for brushing and deburring applications. Two series are being launched: the smaller model with a diameter of 36 mm covers a speed range of 700 to 6,500 rpm and has a maximum torque of 1.1 Nm. The 45 mm model with 700 to 4,500 rpm and 1.9 Nm delivers less spin but more power.

With the new "Burrless Chamfering Cutter", the chamfer cutter has been raised to a new level. The world's first V-shaped cutting edge completely prevents the formation of secondary burrs, eliminating the need for downstream deburring processes. In order to cover as many applications and material groups as possible, the new chamfer cutter is available in different versions, for example for non-ferrous metals, plastics, composite materials and even superalloys.

Brush deburring provides metal and plastic processing companies with a deburring process that can be used for workpiece weights of just a few grams as well as for components weighing several tons. It is also suitable for soft materials as well as harder materials. These properties undoubtedly make this traditional process one of the most flexible of all.

Mass finishing technology

Avatec offers the matching "trolley" workstation for the TE6HD, TE10HD and W10HD mass finishing systems, in which the machine, abrasive media supply, separation and process fluid travel along tidily. Equipped with sturdy handles and locking wheels, the trolley can be set up flexibly and safely with a footprint of less than 1m2. The sturdy design also allows the storage of abrasives in easy-to-handle plastic boxes and two 20-liter canisters for process and waste water.

The hemispherical containers of mass finishing systems are usually filled with polyurethane to protect them from the abrasiveness caused by the process. And yet the ravages of time are gnawing away at this protective coating, usually in the form of localized wear to the point where it breaks through to the bare metal substrate. A professional repair by Metaline is an economically and ecologically sound approach. The first step is to determine whether the existing coating is still bondable and therefore repairable. The company offers support and the right materials, application methods and adhesion promoters so that repairs can be carried out by the customer. If the protective coating is already badly worn, infiltrated or full of holes, the question arises as to whether the "coating residues" need to be completely removed. After complete removal, the system manufacturer can cast in the new lining using his casting mold. For geometrically simple vibratory finishing drums (without flap ejection), a sprayed coating can be applied as an alternative, for which Metaline has the material and the appropriate spraying process.

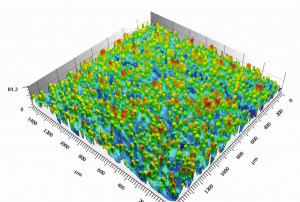

The Isotropic Superfinish makes it possible to achieve optimum results in terms of low surface roughness, increased functional performance of the component and its service life while maintaining the geometry and dimensional tolerances. The results can be achieved with standard vibratory machines used with specific media and products. The processing media are selected based on the material and geometry of the workpiece to be treated. The latest updates to this technology also make it possible to machine additively manufactured components.

Automation

The RFC is a modular robot cell for the automated deburring of different workpieces. Unlike workpiece-guided finishing processes with a fixed number of spindles and therefore a limited selection of tools, this solution is designed for tool-controlled finishing. It therefore offers a very high degree of flexibility in terms of both the mix of parts (size, weight and geometry of the workpieces) and the number of tools provided for this purpose. The robot cell is available as a stand-alone solution or can be integrated into a flexible manufacturing system (FMS) from Fastems.

Mepsa presented efficient solutions for the effective automation of deburring, grinding, polishing, satin finishing and chipping processes for parts made of metal and other materials. The manufacturer of robot cells and special systems ensures the feasibility of the project through prior process and feasibility tests. This helps to ensure that the company's automation solutions meet strict specifications for dimensional accuracy and surface roughness while ensuring an optimum balance between productivity and profitability.

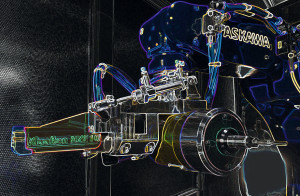

Klaassen Werkzeugmaschinen und Automatisierungstechnik presents the self-learning deburring robot, a world first for the deburring of gear components. The solution, which has already proven itself many times over, enables a wide variety of gear geometries and dimensions to be processed using intuitive operation. No CAD/CAM programming is required. The deburring results and high application flexibility set new standards in the field of deburring gear components. Users can thus forget their fear of contact with robot technology when it comes to deburring. Thanks to its simple operation, the solution is ideal for both small and large series.

Expert forum with theme parks

The high-calibre supporting program at DeburringExpo also provided impetus and expertise for process design and optimization. Like the exhibition, the specialist forum lasted three days. Each day had a different focus: Tuesday was dedicated to mechanical deburring, Wednesday offered topics relating to quality assurance and Thursday was all about non-mechanical deburring. The second day of the forum featured the theme parks "Cleaning after deburring" and "Automated deburring with industrial robots". Solutions were presented and suggestions offered for mastering various current challenges efficiently and sustainably.

The bilingual specialist forum has established itself as an internationally sought-after source of knowledge

The bilingual DeburringExpo specialist forum has now established itself as an internationally sought-after source of knowledge. In a total of 23 simultaneously translated (German - English) presentations, experts from industry, science and research provided information on basic principles, new processes and ways to optimize processes and costs. The presentations, as well as the reports on best-practice applications and trends in various industrial sectors, were characterized by a high degree of practical orientation and relevance. Participation in the specialist forum was free of charge for visitors to DeburringExpo.