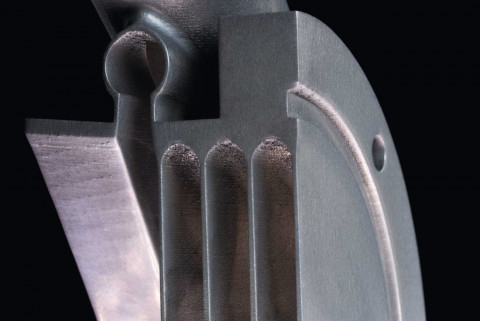

The surface finishing of irregularly shaped objects usually poses considerable challenges for electrochemical surface technology, especially in combination with higher processing speeds and requirements for component precision. Here, classic electropolishing is faced with an impossible task. An alternative here is the process of electroablation, which can be classified as dynamic electrochemistry. The process is suitable for surface finishing and post-processing of metallic objects of all kinds. Recently, this method has also been used in the post-processing of 3D-printed components, especially when hidden or internal surfaces need to be smoothed and processed.

Electrochemical process

Electroablation belongs to the group of electrochemical processes for surface treatment and is generally little known in Central Europe. In principle, the method is similar to classic electropolishing. Here too, metal is removed from the surface of the anodically polarized workpiece by applying a current (potential), thus creating a smoother surface. As with electropolishing, anodic dissolution under electroablation conditions smoothes the surfaces of metal objects due to an increased current density at the micro peaks compared to the micro valleys. The resulting accelerated metal removal at the elevated (roughness-causing) positions leads to a leveling of the surface. The main difference to electropolishing, however, lies in the high speed of the process, caused by the higher current flow compared to electropolishing, and the associated high metal removal rate (ablation). Conventional electropolishing usually uses low (direct) currents, normally less than 0.5 A/cm2, which limits the speed of the electropolishing process. Electroablation is based on a pulsed current with a relatively high frequency, so it is a dynamic electrochemical process. In contrast to electropolishing, which works in a diffusion-limited range of constant current, electroablation uses high currents of up to 100 amps/cm2, well above this diffusion-limited current plateau. As a result, the electroablation process can often run more than an order of magnitude faster than conventional electropolishing. Electroablation was presented for the first time at FormNext 2023 in Frankfurt by the Australian company "3DM Surface Finishing" for the post-processing of 3D-printed metal components

Electroablation was presented for the first time at FormNext 2023 in Frankfurt by the Australian company "3DM Surface Finishing" for the post-processing of 3D-printed metal components

Dynamic electrochemistry as the answer to increased component requirements

The largest share of the polishing market is still accounted for by mechanical or abrasive polishing methods, in which the part is either processed with manual polishing tools and equipment or tumbled and otherwise exposed to abrasives to obtain a smooth surface. These processes are also slow, usually take place in several polishing stages and are not able to evenly process more complex structures with internal surfaces. However, the trend is moving precisely in the direction of more complex component geometries through to free forms from additive manufacturing. Electro-ablation is able to achieve leveling even in holes, valleys and concealed or inner surfaces of metallic workpieces without the use of auxiliary electrodes. Due to the high frequencies used, the smoothing effect is distributed more evenly over all surfaces, including the internal surfaces mentioned above. The process enables the surface finishing of a variety of widely used metals such as titanium, stainless steel, niobium, chrome-cobalt, Inconel and aluminum and their alloys. Although mostly used in conventional surface treatment, electro-ablation was also presented for the first time at FormNext 2023 in Frankfurt for the post-processing of 3D-printed metal components. The Australian company "3DM Surface Finishing" has further developed the process for this application and also offers suitable electroablation inverter systems for its use. Using electro-ablation, the surface roughness resulting from 3D printing can be quickly reduced from well over 5-20 micrometers to values below Ra = 0.1 micrometersµm. This enables efficient use of this finishing process in series production.