In order to be able to separate printed circuit boards, they are scribed beforehand and cut-outs and contours are milled. LHMT develops machine tools on which not only the actual scribing and milling process, but also the loading and unloading of the circuit boards is fully automated. For safe and gentle handling, LHMT turned to J. Schmalz GmbH, which was able to implement a reliable gripper solution with its NBR ESD suction cups, among other things.

Until a finished PCB is ready for installation, it goes through many different process steps - exposure, wet chemical processes such as copper etching, drilling - before it passes through the processing steps in an LHMT machine. The LHMT handling devices are used to load/unload the individual production processes. In the scoring machines, the individual panel - i.e. the entire PCB - is given its predetermined breaking points at the end of its complete production process to enable individual PCBs to be broken out later.

LHMT - which stands for PCB Handling and Manufacturing Technologies - was founded in 2002 and is part of the Schmoll-Maschinen Group, a well-known manufacturer of systems for electronic mass production and microprocessing. The machines produced by LHMT GmbH in Neuhausen near Pforzheim are closely integrated into a modern manufacturing process in their operating environment: LHMT develops special machines in the field of CNC and automation technology as well as robot automation and image processing for the semiconductor industry.

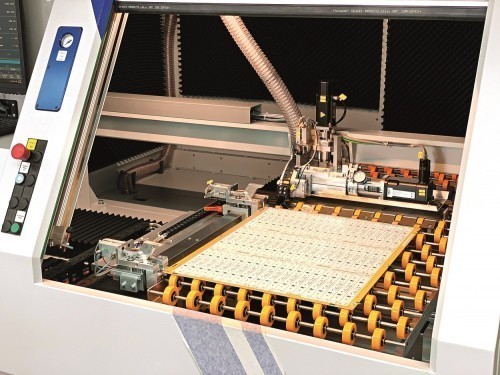

Fig. 4: Instead of a robot, an axis system can also place the PCBs safely on the roller track. The yellow NBR ESD suction cups reliably protect against damage caused by electrostatic discharge

Fig. 4: Instead of a robot, an axis system can also place the PCBs safely on the roller track. The yellow NBR ESD suction cups reliably protect against damage caused by electrostatic discharge

The scribing and milling machining steps give the PCB the external shape required for the subsequent application. "Because the workpieces are becoming ever finer and more sensitive, we rely on a fully automated process here," explains Knut Handte, Head of Design at LHMT. The PCB blanks, which are provided in so-called inclined cassettes or product carriers, are automatically removed individually by a handling device using a 6-axis robot. The pin holders are measured by a CCD camera (charge coupled device) and the blanks are then transferred to the scoring machine.

Sensitive object

"What sounds so simple is actually quite a challenge. After all, not all PCBs are the same," emphasizes Handte. While particularly thin and light PCBs are used in smartphones, servers tend to use thick and solid PCBs with a lot of copper. What they all have in common is the extremely sensitive surface, on which no marks must be left. "That's why gripping is usually done on the outside, on the edge of the panel - and of course with a vacuum," explains the design manager. The gripper not only has to cope with different formats, but also with existing reference holes. The scoring machine is geared towards this and therefore delivers an exact result. In addition, the gripper has less and less space: the complexity of the PCBs is increasing with the need to accommodate more and more functions on ever smaller surfaces. "You also have to bear in mind that different PCBs are processed on our machines - the process steps and the handling system have to be correspondingly universal and flexible. This is the only way we can avoid long set-up times," adds Handte.

This flexibility is a particular challenge for the automated feed system. LHMT, in cooperation with the vacuum experts at

J. Schmalz GmbH, LHMT has developed and tested two different automation solutions. One uses a flexible robot arm that can perform various loading and unloading steps in a small space. Alternatively, the panels can be picked up via an axis system and then placed on the belt conveyor. "Such systems are cheaper than robots, but not quite as flexible. In contrast, the cycle time is much shorter with 2-axis systems: we currently achieve a cycle time of less than six seconds with our RobiFlex2x1 system. When using intermediate layers, the system achieves eleven seconds. All parts are gripped exclusively with a vacuum gripper," explains the design manager. While LHMT developed mechanical components such as the robot connection, gripper structure and axis system, Schmalz supplied the components for the handling process: the suction cups and their connection to the gripper. "Each individual panel must be handled sensitively without leaving marks. At the same time, the fast movement sequences require the plate to be held securely - without deforming it, of course," explains Christian Stoisser, International Industry and Key Account Management Electronics at Schmalz. Another special feature of handling PCBs and other electronic components is the risk of damage caused by electrostatic discharges in power electronics, among other things. This is not visible, but is noticeable at the end of the functional test. "Our milling and scribing process is relatively far down the value chain. This means that the value of the PCB is already very high and we therefore naturally want to keep the reject rate as low as possible," explains Handte.

Fig. 5: Schmalz has combined suction cups, spring plungers and nipples - i.e. the connection - to create a customized solution for LHMT

Fig. 5: Schmalz has combined suction cups, spring plungers and nipples - i.e. the connection - to create a customized solution for LHMT

Dissipative combination

Schmalz has developed NBR-ESD suction cups with a specific resistance especially to protect against unwanted discharge. In combination with the conductive spring plungers FSTIm, the vacuum expert ensures a good connection in every gripper position and thus reliably protects the PCB. The suction cups are mounted on suction spiders that are individually constructed from aluminum profiles. "The lightweight aluminum is a basic requirement for short cycle times. A mechanical gripper would make the assembly too heavy and the robot would not be able to move as quickly," says Head of Design Handte.  Fig. 8: Design manager Knut Handte from LHMT (right) together with Patrik Stejskal, system consultant for vacuum automation at Schmalz

Fig. 8: Design manager Knut Handte from LHMT (right) together with Patrik Stejskal, system consultant for vacuum automation at Schmalz

Once the handling solution is connected to the special machine, the PCB moves into the scoring machine after it has been successfully removed and deposited. LHMT also offers handling devices for loading and unloading complete production steps, for example for cleaning or etching lines. "Six plates per minute is a realistic cycle rate," explains Handte. In between, the handling system still has to automatically and separately deposit the protective layers between the PCBs and react flexibly to cassette changes. "This means that the automation must be much faster in order to ensure continuous loading of the process system and to process all additional tasks just in time." Meanwhile, the fully automatic scribing process of the PCB takes place, following a customer-specific program. Depending on the version, the machine can score both lengthwise and crosswise. After the process, the PCB can be removed automatically without manual intervention. After stripping and final quality control, the PCBs are ready for dispatch and assembly.

"We are very satisfied with the Schmalz solutions," praises Handte. "The quality is right through and through and thanks to the NBR ESD suction cups, we can also offer our machines as an ESD-safe version."

Successful in many application sectors

Schmalz has specialized internationally in automation with vacuum and ergonomic handling systems. The products are used in logistics applications as well as in the automotive industry, the electronics sector and furniture production. The broad spectrum in the vacuum automation business field includes individual components such as suction pads or vacuum generators, complete gripping systems and clamping solutions for holding workpieces, for example on CNC machining centers. In the Handling division, Schmalz offers innovative handling solutions for industry and trade with vacuum lifters and crane systems. With the energy storage business area, the company is building up another mainstay in the field of stationary energy storage systems. Schmalz is represented in all major markets with its own locations and trading partners in more than 80 countries. The family-owned company employs around 1500 people at its German headquarters (Glatten, Black Forest) and in 19 other companies worldwide.