In the production of printed circuit boards, depth machining processes in particular require an intelligent and intuitive control system. Ernst Lenz Maschinenbau GmbH relies on the SLM (Smart Layer Management) software package, which Sieb & Meyer has developed in addition to its proven CNC controls. The smart tool makes it easier for machine developers and users to meet increasing demands on the quality and process accuracy of processing machines.

The trend towards ever greater functional integration density of assemblies is continuing - this is also evident in PCB production. Increasing signal speeds require a clean PCB design and high production quality. Ever greater process accuracy is required, particularly in deep drilling and milling, and the number of quality-determining parameters is increasing. Relevant production data must also be recorded and saved for analysis and quality control. In order to meet these requirements, Sieb & Meyer AG has developed the optional SLM software package for the CNC 84.00 control generation.

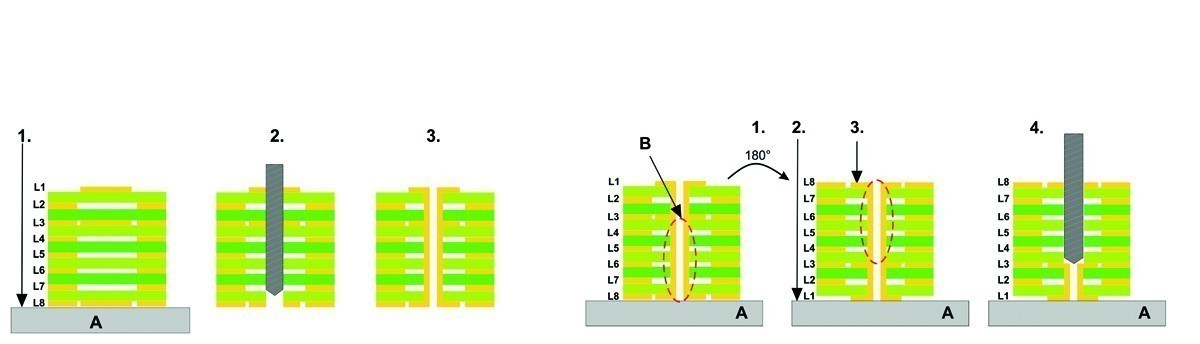

Vias with open ends can lead to signal interference with high-frequency signals due to the antenna effect. This effect can be eliminated with backdrilling: 1) multi-layer PCB, 2) drilling, 3) through-hole plating between the layers, 4) after turning the PCB, the through-hole plating is drilled out to the desired position. The backdrilling function of the SLM software package enables precise drilling to the depth of the layer in the PCB

Vias with open ends can lead to signal interference with high-frequency signals due to the antenna effect. This effect can be eliminated with backdrilling: 1) multi-layer PCB, 2) drilling, 3) through-hole plating between the layers, 4) after turning the PCB, the through-hole plating is drilled out to the desired position. The backdrilling function of the SLM software package enables precise drilling to the depth of the layer in the PCB

One of the objectives of the development was to meet the increasing demands of the market for deep processing. This applies, for example, to processes such as backdrilling or residual web milling. Secondly, the focus was on an innovative implementation that would continue to inspire users in the years to come. A third, increasingly important aspect is usability: "Despite the extensive functionality, the operator should be able to set up the necessary process parameters easily and comprehensibly," explains Holger Dornau, Head of Sales/Marketing CNC at Sieb & Meyer AG.

Software package opens up new possibilities

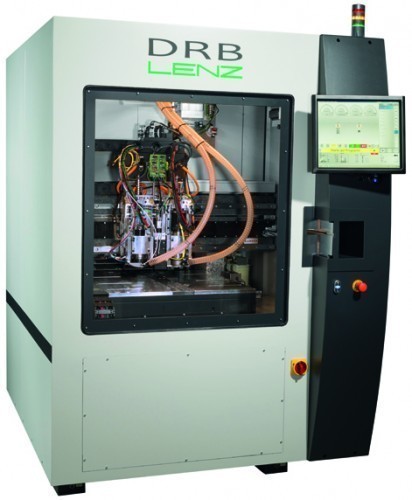

Ernst Lenz Maschinenbau GmbH has already decided to use the innovative software package. "We have been building drilling and milling machines for the PCB industry since 1968," says Managing Director Uwe Lenz. "Our focus is on special applications and niche solutions." Although deep processing of printed circuit boards has long been standard, the demands on accuracy are becoming ever greater. With the DRB 610-1+1 drilling and milling machine, Lenz has therefore developed a series in which the PCB is aligned in the X-Y position using a CCD camera and can be measured in the Z direction using various depth measurement sensors. "The CNC 84.00 machine control used here already guarantees a high degree of accuracy, productivity and availability," says Uwe Lenz. "The SLM software package also enables us to record and calculate the measured tolerances of the PCB and take them into account in the work process in real time."

Drilling and milling machines from Ernst Lenz Maschinenbau GmbH with CNC 84.00 machine control (Image: Ernst Lenz Maschinenbau GmbH)

Drilling and milling machines from Ernst Lenz Maschinenbau GmbH with CNC 84.00 machine control (Image: Ernst Lenz Maschinenbau GmbH)

The tool enables high-precision processing of the PCB using various powerful processes - the top or bottom side of the PCB or the top side of the base can be taken into account as a reference plane.

The percentage mode allows additional consideration of thickness variations within the PCB. "Typical applications from the deep processing of PCBs include backdrilling," says Holger Dornau. "Among other things, this produces very expensive PCBs for the IT industry. This technology can also be used for deep milling very precise embedded structures on PCBs for automotive applications." The SLM software package enables Lenz to record and calculate the measured tolerances of the PCB and take them into account in the work process in real time (Image: Ernst Lenz Maschinenbau GmbH)

The SLM software package enables Lenz to record and calculate the measured tolerances of the PCB and take them into account in the work process in real time (Image: Ernst Lenz Maschinenbau GmbH)

Compensating for thickness tolerances

"Our DRB 610-1+1 is used to process thick PCBs with 20 or more layers, which are specifically required for the IT sector," confirms Uwe Lenz. "They are used, for example, as back panels for fast internet switches." Backdrilling involves drilling out vias in holes up to a certain position so that they do not act as interfering antennas in the high-frequency range. As these are very thick, multi-pressed PCBs, the thickness tolerance is very high and must be measured and compensated for. SLM helps with this.

The software package is also ideal for milling cavities. The background: embedded components are becoming increasingly popular in the electronics industry. Manufacturers have to create a very precise and flat surface with very small tolerances in the PCB. "These are also multi-pressed multilayers where the thickness tolerances have to be compensated for," says Uwe Lenz. "The required tolerances are in the micrometer range. This is definitely a challenge, but one that can be mastered well with the software from Sieb & Meyer."

Intuitive to set up and operate

The process setup is also easy to manage: "It takes place exclusively on content-coordinated and easy-to-understand input pages of the CNC software," explains Holger Dornau. Parameters such as the thickness of the infeed material or a fixed depth offset ensure the process accuracy of the CNC machine. Once set, the operator can save the parameters in a configuration file and use them again later. Determined surface data can also be saved and reloaded later for reuse. "SLM gives us the opportunity to respond to the different needs of our customers in deep machining and to anchor individual adjustments in the program in advance," emphasizes Uwe Lenz. "The machine operator can simply define individual product-relevant machining steps in advance and then only has to read in the program tailored to their needs."

During operation, the CNC software guides the user safely through the production process, which significantly reduces potential operating errors. The levels determined are displayed in tabular form by the software. Output to a file takes place automatically once the measuring or machining process has been completed. Subsequent analysis of this data allows direct conclusions to be drawn about the production quality achieved. The operator can also display the surfaces within the program graphics. The color tone and saturation give him a quick visual impression of how even the determined surface is. With the control package from Sieb & Meyer, Lenz can serve every customer and, above all, unusual areas of application (Image: Ernst Lenz Maschinenbau GmbH)

With the control package from Sieb & Meyer, Lenz can serve every customer and, above all, unusual areas of application (Image: Ernst Lenz Maschinenbau GmbH)

Exploiting potential and meeting challenges

"We have achieved our original objective," concludes Holger Dornau. "We have created a future-oriented control package whose possibilities go far beyond current requirements." So there is still room for improvement - particularly important for customers like Lenz, who have to deal with very different applications on a daily basis, but which can all be served by the software package. Although there will rarely be a customer who really needs all the functions - conversely, Lenz can serve every customer and, above all, unusual application areas from the range of the software package. "The SLM tool is a way for us to set ourselves apart from the competition," concludes Uwe Lenz. "It is the perfect complement to the CNC control system from Sieb & Meyer. Everything builds on each other logically."-dir/vti-

https://lenz-gmbh.de/cnc-maschinen/

www.sieb-meyer.de/alle-produkte-der-cnc-steuerungssysteme.html

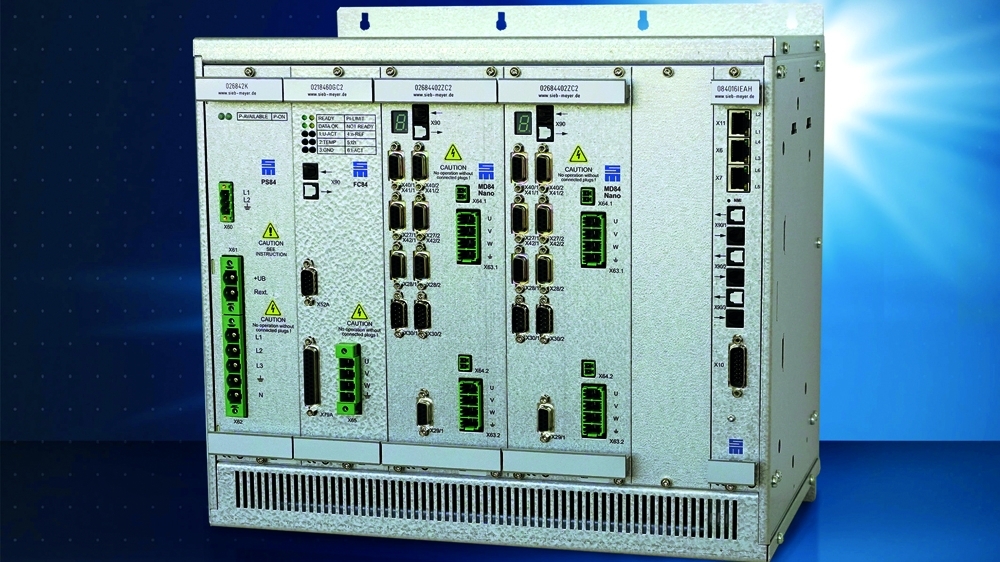

CNC controls are the mainstay

CNC controls are Sieb & Meyer's mainstay. These solutions have been continuously developed since the start of CNC production a good 40 years ago and continue to write their success story. Sieb & Meyer sees itself as a system supplier that provides its customers with a product that is perfectly tailored to PCB drilling and milling applications - including software interface, CNC axis controller, frequency inverter, servo amplifier and, last but not least, the appropriate I/O terminal.

Lenz DRB 610-1+1 AL

PCB drilling and milling machine with:

- air-bearing drilling spindle up to 200,000 min-1 or 300,000 min-1

- ball bearing milling spindle up to 60 000 min-1

- automatic spindle changeover

- Contact deep drilling

- contact depth milling

- Mechanical depth milling with 2nd measuring system

- CCD camera system for position alignment

- SLM software package from Sieb & Meyer

- Automatic loading and unloading system