As a non-contact tool, the laser has enormous potential for a wide range of applications in the automotive industry. The use of laser technology promises high quality, flexibility and cost efficiency in PCB depaneling for the industry.

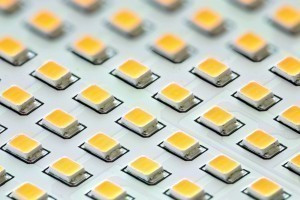

PCBs are used almost everywhere in vehicles: in on-board electronics and sensor technology, in lighting and in many other automotive applications. PCBs must meet very high quality requirements, especially in safety-relevant applications. To ensure this, every detail is important in PCB production. Fig. 2: IMS application before depaneling

Fig. 2: IMS application before depaneling

During depaneling, the final step in PCB production, the boards are separated from a panel. In contrast to mechanical separation processes such as milling or punching, no dust is deposited on the assembled PCBs during the laser process, which could lead to malfunctions during subsequent use. The separation process is gentle; the mechanical or thermal component stress caused by lasering is negligible.

Laser technology can be used to implement standards in terms of technical cleanliness - for example in accordance with VDA 19 / ISO 16232. LPKF's CleanCut technology enables carbonization and discoloration-free processing of the substrate. The result: high-quality PCBs with maximum technical cleanliness. The process thus prevents potential component failures during use. The output for the user is therefore high, especially for sensitive components such as sensors.

The diversity of processable materials for the laser ranges from standard applications such as FR4, flex or ceramic to insulated metal substrates (IMS) and system-in-packages (SiPs). By adjusting the parameters, different materials and material compositions can be processed with the same tool.

The variety of materials of the technically clean and precise laser-cut PCBs allows them to be used in different application environments: From heat and cold, as present in the engine compartment or, for example, in sensors in the chassis, to pressurized environments such as tires.

The design of the PCB is subject to few restrictions: Contours do not have to be straight, there are no minimum radii, webs to be taken into account or similar limitations. The precision of the cuts is very high thanks to the specifically controllable laser beam, whereby the respective cutting channels are extremely narrow. With a full cut, the individual PCBs can be aligned on the panel in a space-saving manner without larger separation channels. Compared to mechanical separation processes, material savings of more than 30% can be achieved.

This type of laser system can be easily integrated into existing Manufacturing Execution Systems (MES). Thanks to sophisticated software, they achieve a high level of process stability. Extensive automation simplifies handling. Thanks to the increased power of the integrated laser sources, the cutting speed is fully competitive with mechanical systems. Fig. 3: The LPKF CuttingMaster is used for depaneling and can be optionally equipped with an automation solution and a variable cobot

Fig. 3: The LPKF CuttingMaster is used for depaneling and can be optionally equipped with an automation solution and a variable cobot

The follow-up costs are low as it has no significant wear parts such as milling heads. This means that there are no ongoing parts costs or production stops for replacements. The laser can also be used for marking, drilling or ablating individual layers of material.