Over the past twelve months, Schweizer Electronic has implemented important measures to consolidate and expand its position as one of the leading international PCB manufacturers. The following is a brief insight into the company's future-oriented planning.

In the NTI Top 100 list of the world's leading PCB manufacturers with an annual turnover of more than USD 100 million, Dr. Nakahara positioned Schramberger Schweizer Electronic AG in 97th place for 2018, but four places lower in 2019 at position 101. Turnover fell by around 3.5 % from 2018 to 2019, while companies in the neighbouring list increased their turnover.

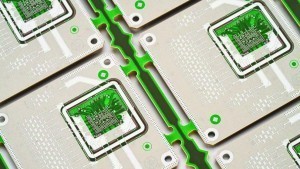

In the coronavirus year 2020, the family-run stock corporation, like many other manufacturers, also suffered considerable losses in turnover in board production, not least due to the weakening automotive industry. The management temporarily introduced short-time working and adjusted the workforce at the main site in Schramberg to the situation by various means. Specifically, this meant that it also had to lay off employees. Today, a workforce of 1000 employees is reported. In order to halt this downward trend and turn it into an upward trend, the company took various measures as early as 2020 as part of a new corporate strategy geared towards the future and continued these in the first quarter of 2021:  Fig. 1: Schweizer Electronic's new PCB factory in Jintan (China)

Fig. 1: Schweizer Electronic's new PCB factory in Jintan (China)

- Significant increase in PCB production capacity from 2021 with the new PCB factory in China

- Expansion of the distribution channels

- Acceleration of the automation of board production

- New internet presence

- More political involvement in the electronics industry.

Capacity expansion

The commissioning of the new high-tech PCB plant in Jintan (China), combined with the gradual realization of the necessary certifications as an automotive supplier such as ISO 9001, VDA 6.3, IATF 16949 (Automotive), will significantly increase Schweizer's overall capacity in PCB production(Fig. 1). According to company information, the new plant will have around five times the capacity of the plant in Schramberg. Around €100 million had been invested by mid-2020, with around €40 million more to follow. According to Nicolas Schweizer, CEO of Schweizer Electronic AG, the company management believes that the two production plants in Germany and China are well positioned for the future with regard to the different requirements of all market segments. If the production capacities can be optimally utilized, the company should be able to move up several positions in the future NTI 100 list. While the expansion of capacity is primarily focused on Asia, the main aim of German production is to expand the technological capabilities of production in order to secure the Schramberg site in the long term(Fig. 2, 3).

More distribution channels

A logical measure taken by Schweizer in connection with the commissioning of the new high-performance plant in China is the expansion of sales channels, particularly in Asia itself. In August 2020, the company announced that it had signed a sales representative agreement with Varikorea Co. Ltd. in South Korea [1]. The partner is now authorized to distribute high-tech PCBs from Schweizer Electronic AG and its embedding solutions in its sales territory. The Schramberg-based company is thus entering the South Korean electronics market. The aim is to supply the country's high-performance automotive industry in particular. Varikorea acts as a total solution provider specializing in the automotive and industrial markets, backed by strong local technical support in display products, semiconductors, embedding solutions and robotics. On its main website, the company demonstratively presents a selection of Epson's Scara-type articulated arm robots, and on other pages automation solutions with these robots. The Epson Robot Management solutions could also be used in the German electronics industry.

Schweizer currently has four locations (Schramberg, Jintan and Jiangsu in China, Singapore) and four additional sales partners (Nisko in Israel, Neutronics for USA/Canada, Nagase for Japan, Varikorea for South Korea) on its world map on the new website. Here is a small note on these entries: The color coding for the locations and sales partners differs so minimally that you have to look very carefully to see which color dot means what. You can only be sure by clicking on the dots and the window that opens. Although these are minor details, they could have been solved more clearly by using more distinct color differences when redesigning the website. High-contrast color selection is also a feature in PCB production, e.g. for solder resist.

Automation

PCB manufacturers are investing in the automation of their production, especially during the challenging coronavirus period, in order to be prepared as soon as the recovery begins. This was reported on in detail in the PCB section of Plus 12/2020. Modernization of production facilities with the aim of ensuring competitive PCB production in Germany through highly efficient automated production is easier to implement in times of underutilized production lines. Schweizer is evidently following this path and taking measures to raise PCB production to a higher, long-term competitive level through automation and to prepare for the future requirements of Industry 4.0.

The Spanish company Technosystem announced in January 2021 that it was supplying automation systems for the PCB production of Schweizer Electronic AG in Schramberg [2]. Technosystem always approaches such projects with the aim of optimizing throughput times in the customer's PCB production. According to the company, the automation systems are adapted precisely to the individual needs of the user in terms of space requirements, process speed and the available hardware and software.

The specific project involved the modernization of a

brown oxide line in the production of printed circuit boards. Key requirements for the high-end automation included cycle times of 12 seconds per cut, the fast automatic exchange of boxes or L-racks without interrupting production and the contactless alignment of the working formats using CCD cameras. Robotic arms were implemented that can also handle thick copper blanks weighing up to 4.5 kg at high speed. Technosystem quoted Schweizer's procurement team as saying that by using the latest technologies, all key objectives of automation in production could be met or exceeded.

Technosystem is part of the Spanish Gabriel Benmayor SA, a group of companies with quite different production directions [3]. Since its foundation 25 years ago, the company has specialized in the development and manufacture of automation systems for the PCB industry. One field of activity is the automation of the handling of printed circuit boards in their various processing stages using robots. According to [2] and [3], Schweizer probably uses a system similar to the Millenium V4 with two 6-axis high-performance robots for handling (loading and unloading) the boards in the system(Fig. 4). More detailed information from Schweizer is not available. The management generally reports little about technological changes in press releases.

New Internet presence

In the past, the author of this report has repeatedly pointed out the growing importance of 'appealing' and informative websites for companies. The special conditions during the corona pandemic further underlined the fact that in times when important industry trade fairs in the traditional form such as electronica or productronica are no longer taking place, company websites are becoming even more important. They are the  Fig. 5: Nicolas-Fabian Schweizerdigitalshowcase for companies' self-presentation. They allow companies to communicate with their customers around the clock and acquire new customers.

Fig. 5: Nicolas-Fabian Schweizerdigitalshowcase for companies' self-presentation. They allow companies to communicate with their customers around the clock and acquire new customers.

It is pleasing to see that Schweizer Electronic evidently sees the redesign of its website as an important component of its package of measures to strengthen its market position and realign itself for the future of the company.

In its press release dated March 1, 2021, the management writes, among other things "The new company design and website, which will go online on March 1, 2021, are another important step by Schweizer on the way to a new era in the company's history. With the new production plant in China, the location in Singapore and the headquarters in Schramberg, it is important for Schweizer to also adapt its digital appearance to the global, growth-oriented and innovative focus of the company."

The press release also states: "The new website focuses on consistent customer and solution orientation. A target group-oriented, digital approach to existing and new customers is crucial, especially in such challenging times. When personal contact with customers, partners and investors is not possible, an innovative, digital presence is particularly crucial. Thanks to the modern structure and detailed presentation of technologies, solutions and products, coupled with an increased focus on innovation and service, Schweizer Electronic AG is doing more justice than ever to its connection between Germany and Asia and its claim to be a global company. This will be realized step by step in different languages. In addition to intuitive user guidance, great importance was also attached to usability on all types of end devices - from smartphones to desktops. Together with communication via social media, the new website now rounds off the company's presence in the digital world

The author found the design with large, high-contrast fonts, skillful background design, lively images from the company's operations, lots of textual and pictorial specialist information very appealing and stimulating. The new Internet pages could really reflect the fact that Schweizer is competent in supplying a huge range of PCB requirements in the electronics industry.

The establishment of the new Systems division is a further logical consequence of the company's future-oriented planning. Through system solutions, including embedded technologies, customers benefit from the customized form factor, improved electrical and thermal performance, the option of active IP protection and increased reliability. Printed circuit boards are increasingly becoming system carriers based on integrated passive and active components of various kinds. The aim is always to further reduce system costs, but also to contribute to increasing environmental protection and energy efficiency.

Schweizer takes over the chairmanship of the ZVEI PCB-ES trade association

Schweizer not only wants to make himself more visible on the Internet, but also at the political level of the electrical engineering/electronics industry. The fact that Nicolas-Fabian Schweizer has stood for election as the new Chairman of the ZVEI Printed Circuit Boards and Electronic Systems (PCB-ES) Association underlines this. With his election as successor to Johann Weber, the trade association now has the CEO of a major company in the PCB industry at the helm, after a chairman who led Zollner Elektronik AG, a major company in the EMS sector (see also 'News PLUS'/www.plus-fachzeitschrift.de).

References:

[1] http://varikorea.com/

[ 2 ] https://evertiq.de/news/26587

[3] https://techno-system.es/